Why fittings are knitted. How to correctly knit and bend reinforcement for foundations: installation technology. Toolkit and materials for knitting themselves

Building symbiosis. It seems like a concept from biology. Animals and plants enter symbiosis, that is, mutually beneficial cooperation. One, for example, can serve as a home for another, receiving useful substances from the "lodger" or protection from viruses.

What is the construction symbiosis? Let's look at an example and. The latter is stiffened by steel rods, saving it from destruction. Concrete, on the other hand, saves the reinforcement from oxidation, rust, closing it from the harmful effects of the atmosphere and moisture on the metal.

For symbiosis to work, you need to learn correctly knit reinforcement... Without preliminary adhesion of its rods, walls, interfloor ceilings are not poured. Why? About this and not only, further.

Why knit rebar

To understand why knit reinforcement, you can know the scheme for pouring reinforced concrete structures. First, the metal frame is exposed. However, there are also composite fittings. The latter is lighter in weight and is rolled into coils.

The first is inflexible and heavy. But, the principle of operation of the classic and modern frames is the same. A kind of network is made of rods in the center of the foundation, wall, concrete. The armature is in the center and should remain.

Moving to the edges of the fill, the frame will redistribute the loads in the final structure and become vulnerable. Close to the concrete surface, water vapor can "reach" the reinforcement, provoking metal corrosion. That is why the rods are tied together so that the base does not "float" under the poured concrete mixture.

How to knit foundation reinforcement

Question, how to knit reinforcement for the foundation, is popular, since the laying of rods in the foundation is always required. A metal network is needed even under a private house, not to mention multi-apartment high-rises.

Under the latter, it is customary to fill in monolithic bases, that is, solid slabs. For private houses, often enough strip foundation. How to knit reinforcement for both? The same. There are several ways:

Classic knitting of reinforcement

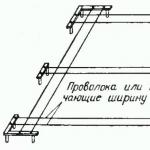

We take steel wire with a diameter of 0.8 to 1.2 millimeters. The exact diameter depends on the width of the rebar. It can be from 6 millimeters to 8 centimeters. The degree of strength that the metal will give to the concrete pour depends on the diameter.

Classic crochet reinforcement

However, this strength is associated with quality, as well as the type of knitting. In addition to manual connection of fittings, there is a welding option. The latter is rarely resorted to, since the docking is hard.

The frame does not have any gaps for the "right" or "left" step. Such shifts are needed for critical loads on the foundation. Where welded joints break, knitted joints will only stretch, preserving the integrity of the structure.

The main load in the foundation is carried by the longitudinal reinforcement rods. Transverse - their support. Tie the corners of the frame and the intersection of the rods. Usually, the fastening wire is used with pliers. They twist the ends of the strapping, fixing it securely. The shape of the mount is a single hinge.

Crochet and screwdriver reinforcement

Crochet reinforcement does not imply an openwork net, as some ladies might think. The hook for the foundation frame is not so much a knitting needle as pliers that remove unnecessary ends of the wire.

Tying reinforcement with a screwdriver

Before this, the fastener is hooked up and twisted into a bundle. The crochet hook also helps to make this loop lock. He picks up the wire. It remains to make rotational movements.

They are made by hand or using a screwdriver. The latter speeds up the knitting process by about 5 seconds on each loop. In order for the method to work, the ends of the wire are inserted into the screwdriver chuck and turned on.

Knitting of fittings with a gun

A gun for fittings is an electrical device powered by a battery. The device speeds up, partially automates knitting. One knot with a pistol takes 1.5-3 seconds, as opposed to at least 10 seconds with other methods of connecting the rods.

Knitting of fittings with a gun

A microchip in the gun adjusts the tension of the wire when tying. Convenient, because with manual connection it is rarely possible to make identical knots. One may be tight and the other flimsy. The wire for tying in the gun is wound on the drum. The part is removable. This saves working time. A new drum immediately replaces the old one.

You have to pay for the convenience of working with a pistol. The device is expensive. Therefore, a reinforcement gun is used, as a rule, on large construction sites that need to be completed in a short time. In private home construction, hooks and pliers are preferred.

Tying reinforcement with staples

A staple is a piece of wire. It has already been folded into a loop. It remains only to tighten it. As a result, the process of knitting the compound is accelerated by 3-4 times. The skill for working with staples is minimal, and a beginner masters the process in just a couple of hours.

Tying reinforcement with staples

In addition, each bracket is of a standard size, which ensures uniformity and stability of the connections. The ease of budgeting is also attractive. One bracket is needed for one joint of reinforcement rods.

Buying wire in coils, you have to take into account the footage, divide it into the approximate length of one fastener. In general, if planned do-it-yourself reinforcement knitting, staples are a convenient and affordable option. The price tag for blanks is slightly higher than for ordinary wire. But, the time saved on mating covers the costs.

Tying reinforcement with clamps

Clamps - plastic "belts". They have the appearance of plaques. The end of the strap is inserted into the plaque and tightened. Fastening is not as reliable as wire, but it is enough to fasten the rods in the foundation of a private house.

Tying reinforcement with plastic clamps

In addition, plastic has advantages over steel reinforcement. The polymer does not rot, even if it comes into contact with water. Besides, working with clamps is simple, non-traumatic. Wire, you can still get hurt, scratched.

Self-sufficiency becomes an additional advantage of the clamps. No additional tool is required for working with plastic belts. Only now, in subzero temperatures, it is difficult to use polymer mounts. Plastic dubs in the cold. The connections are poor. But you can work with wire in any weather.

Most often, clamps are remembered when deciding how to knit fiberglass reinforcement for the foundation... The design is 100% polymer, excluding the weakness of the metal in terms of intolerance to atmospheric phenomena and moisture. However, there are also complex clamps.

Thin wire is implanted into such. Plastic protects her and makes her work easier. But, clamps, even ordinary ones, are about 3 times more expensive than wire for a similar number of fasteners.

Double knot reinforcement

The already described tying methods provide sufficient fixation of the reinforcement rods laid in the foundation pit. However, if the frame needs to be made separately, and then transferred to the main place, it will fold. Welding gives a rigid fixation, but its disadvantages have already been mentioned.

It is desirable to leave the minimum backlash to the rods. Double knitting "comes to the rescue". It requires hard training and consists in the simultaneous tightening of steel rods from both sides. In words, the scheme is difficult to explain. It's easier to watch the tutorial video. It should have 5 steps. Exactly so much in double knit.

There is also a scheme for connecting two spatial frames into one volumetric one. It already consists of 6 steps. Having mastered them, you can harvest the fittings in advance, while the foundation pit and the formwork are being prepared. Then, all that remains is to transfer the frame.

How to knit corners of foundation reinforcement

Knitting corners is a separate issue, since they account for the lion's share of the load. In addition, the corners are straight, sharp and obtuse. A suitable knitting method depends on the configuration. Blunt joints are made rigid, overlapping.

Correct knitting of foundation corners

It is produced by bending one of the free ends of the reinforcement. After that, the inner horizontal rod is attached to the same outer one. An internal horizontal rod is attached to the resulting bundle.

Fasten with a foot. In length, it is equal to 35-50 diameters of longitudinal reinforcement. As for the step between the corner transverse rods and the vertical ones, it is equal to 3/8 of the height of the foundation.

The corners of the abutments in the foundation are fastened with U- or L-shaped clamps. The 90-degree joints of the reinforcement rods are usually fixed with L-shaped anchor elements. The process almost always consists of 5-6 steps. To master them means to provide the house with a bright, that is, a strong future.

Experienced builders know that the strength of the base under the walls of the house directly depends on the correctly selected scheme of the reinforcing frame to create a strip foundation, and the correctness of the installation. In this structure, all, so to speak, "duties" of its constituent elements are clearly distributed. So, the reinforcement takes on deforming linear stresses arising not only from the severity of the walls, but also from temperature changes, and the concrete part of the structure prevents its compression. Thus, in combination, these materials create a reliable support for the walls.

Tying reinforcement under a strip foundation is the best option for fastening the metal "backbone" of a reinforced concrete structure. Such a connection, while maintaining the specified linear and spatial forms of the frame, nevertheless leaves the opportunity to somewhat "balance" when concrete hardens and gains its brand strength, assuming an optimal position when exposed to emerging loads. If we make the skeleton of the foundation rigid, that is, fasten the reinforcement by welding, then even with a slight shrinkage of the soil or under the pressure of the walls of the house, the concrete part of the structure may begin to collapse, since when the solution solidifies, there was no optimal shift of the frame parts and in a seemingly solid monolithic the plate retains significant internal stresses.

Reinforcement of reinforced concrete structures is a key factor in determining their reliability and durability. Concrete structures are reinforced with reinforcing cages assembled with knitting wire, which we will talk about in this article.

The publication presents a wire for reinforcement, considers the scope of its use, varieties and features of application. Provides instructions for calculating material consumption and recommendations for its selection.

1 Knitting wire - where and why is it used?

Reinforcing wire is used in the field of individual and industrial construction for the manufacture of frames used to reinforce reinforced concrete structures. By means of a knitting wire, adjacent reinforcement bars are connected at the point where they overlap.

The material can be used when assembling the following types of frames:

- foundation (tape, monolithic, columnar);

- floors (basement and interfloor);

- floor screeds.

The most common wire for reinforcement in monolithic construction. In the industrial production of reinforced concrete products - piles, floor slabs, reinforced concrete blocks, their frames, in order to save time, are joined using spot welding.

1.1 How to calculate material consumption?

According to the provisions of SNiP, the consumption rate of knitting wire when assembling the reinforcement cage is 30 cm per connection or 4 kg per ton of reinforcement... To find out how much material you need to use, you need to determine the number of reinforcement coupling points in the frame and calculate the total consumption.

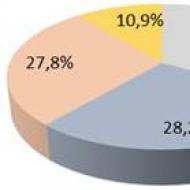

As an example, we give the calculation of the wire consumption for the reinforcement of the tape-type foundation. We use the conditional size of the foundation 5 * 6 m, it will have 2 belts of longitudinal reinforcement - upper and lower, 3 rods in each, connected by vertical and transverse bridges with a step of 40 cm.

Flow rate determination algorithm:

- We calculate the frame perimeter: 5 * 6 = 30 meters.

- Determine the number of jumpers based on a step of 40 cm: 30 / 0.4 = 75 pcs.

- Each jumper will have 6 joining points (3 rods on each belt), we determine the number of connections: 75 * 6 = 450 pcs.

- We calculate the consumption of knitting wire: 450 * 0.3 = 135 m.

In total, to connect the frame rods, we need to use 135 meters of material. In a similar way, having determined the number of connections and multiplying them by the standard consumption, it is possible to calculate the total consumption of wire for assembling the reinforcement cage of any configuration.

2 Classification and varieties

Reinforcement wire is classified into varieties according to such parameters as:

- the presence or absence of a protective coating;

- heat treatment;

- strength class.

Depending on the availability of a protective coating, the material is divided into two types: made from ordinary and. The coating is applied by hot-dip galvanizing, which involves holding the coils of wire in baths of molten zinc.

The material with a protective coating is divided into two classes - 1C and 2C. The differences between them are in the thickness of the galvanized layer, in the material of class 2C the protective layer is much thicker: for comparison - 155 against 85 g / m2 in a wire with a diameter of 6 mm. An alternative to galvanized materials is MNZhKT wire made of a copper-nickel alloy, but its use in construction is unjustified due to its high cost.

By the type of hardening, the reinforcing wire is classified into untreated and annealed (it has the letter O in the marking). The essence of heat treatment is to heat the material to a predetermined temperature in a blast furnace and then cool it down. As a result of annealing, the crystal structure of the metal changes and the internal stress of the steel is destroyed, which provides increased elasticity and mechanical strength of the wire.

Depending on the strength class, the products are classified into two groups B-1 (normal) and B-2 (high strength). The difference between them lies in the grade of the alloys used, for the manufacture of B-1 wire, low-carbon steel is used, for B-2 - steel with an increased number of components. The V-2 material is used to connect frames made of prestressing reinforcement, while class B-1 is intended for the installation of non-stressed structures.

2.1 Sizes and weights

Material diameter depends on the presence of a protective coating - galvanized wire is available in diameters 0.2-6 mm, without coating - 0.16-10 mm... From the factory, products are delivered in coils (weight from 15 to 250 kg) or spools (500-1500 kg). The coil should consist of one piece of wire, the coil should be no more than 3 pieces.

We give a table knitting wire weight 1 meter, BP brand, the most demanded on the market:

- VR-1 (diameter 1 mm) - weight 0.012 kg;

- VR-2 (diameter 2 mm) - weight 0.025 kg;

- VR-3 (diameter 3 mm) - weight 0.06 kg;

- VR-4 (diameter 4 mm) - weight 0.1 kg;

- VR-6 (diameter 6 mm) - weight 0.23 kg.

A characteristic feature of the BP brand is the presence of corrugated walls, due to which the adhesion (adhesion) of the material to the reinforcement bars increases, which has a positive effect on the overall strength of reinforced concrete structures.

Wire "Kazachka

"Recently, wire for tying reinforcement with rings, also called "Kazachka", has become widespread on the market. It is available in 8, 10, 12 and 14 cm lengths, at the ends of which there are rings for a crochet hook. The connection of the fittings "Kazachkoy" is performed much faster than the standard analogue, since there is no need for cutting and independent formation of rings. The material is supplied in the form of bobbins, consisting of 1-5 thousand pieces.

2.2 Wire tying of reinforcement (video)

2.3 How to knit?

To assemble the frame from 10-14 mm reinforcement bars, you need use wire with a diameter of 1.2-1.4 mm... If the material has poor elasticity, the bay must be kept in a fire for 20-30 minutes, and then allowed to cool at natural temperature. It is possible to use products of a smaller diameter, however, in this case, when performing the connection, you will need to bend it twice.

A high-quality mesh made of reinforcement allows you to maintain a certain geometric shape of the foundation when poured with concrete. It is not recommended to cook it due to violations of iron crystals. Regardless of how large-scale the building you will build, reinforcement for the foundation is an integral element. Now there are many ways known how to knit reinforcement for the foundation. You can do this yourself.

A few words about the features of the strip foundation

During construction, due attention must be paid to the foundation. A reliable base will be able to withstand the enormous weight of the future building, therefore, it needs reinforcement with reinforcement. The strip foundation is laid along the perimeter of the building. Such a base can be chosen for any type of building.

Strip foundation when building a house

There are four main types of foundation masonry (foundations, foundations):

- trapezoidal;

- pillow;

- stepped;

- rectangular.

The best option is a trapezoidal shape, since it better withstands the huge load on the base. It is necessary to accurately calculate the slope of the side face to the vertical. For a stone or brick foundation, it should be no more than 30 °. If the base is made of concrete, then the angle should not exceed 45 °.

What kind of reinforcement is used for knitting the frame

There are two main types of reinforcement - metal and composite. Diameter is the main indicator that determines its brand. The thicker the rods, the more load they can withstand. The diameter is calculated at the design stage, taking into account the mass of the future building, as well as the heaving of the soil.

When building a building made of concrete, brick, which is massive, the use of thick rods is required. They can handle the enormous weight of the structure. It is forbidden to use rods with a diameter of less than 12 mm when laying the base - they will not withstand such a load. When building small houses and garages from gas, foam and heat blocks, you can use not so thick reinforcement, enough rods with a diameter of 12 mm.

Metal reinforcement for foundations

Metal reinforcement for foundations In the construction of massive structures, class A-3 is used. The rods of this brand can be bent up to 90 °. Much less often, class A-2 is used for laying foundations. When cold, they can bend up to 180 °.

The most common type of pipe-rolling used when laying a foundation is metal fittings. On sale there are rods of different cross-section diameters - from 12 to 40 mm. They are widely used in construction, in particular for laying foundations for large, heavy buildings.

The cost of a product directly depends on its characteristics, namely:

- rental method,

- steel grades,

- surfaces (grooved or smooth).

Corrugated rods have a higher price. This type has stiffening ribs, which allows the products to better adhere to concrete.

Composite reinforcement is understood as non-metallic rods made of different materials used in construction. For more effective adhesion to concrete, the surface of the rods is roughened or covered with sand.

The most common types of composite rebar are:

- carbon fiber;

- basalt plastic (ABP);

- fiberglass (ASP).

Accordingly, they produce reinforcement from materials: in the manufacture of carbon fiber, carbon fibers are used, for the production of ABP, basalt fiber is used, for ASP - glass. They have many advantages: corrosion resistance, high specific strength, environmental friendliness.

Reinforcement distribution schemes in the structure of the strip foundation frame

The optimal scheme is considered, where in a strip foundation, with a cross section, the reinforcement will represent a rectangle. Two forces act on the base at once: the first is heaving in frost, the second is the pressure of the house. What reinforcement is used for strip foundations to compensate for these two forces?

The material does not play a major role here. To compensate for the influence of these two forces, two belts of reinforcement are installed. The first is at the top, the second at the bottom. If the foundation is laid shallow (up to 1 meter), then this is quite enough. For a foundation that is laid deeper, a third reinforcement belt is required. Greater heights need reinforcement.

There are four main schemes for tying reinforcement for strip foundations. Regardless of the method chosen, the first step is to make a hook from wire, the diameter of which should be 3-4 mm. You can knit the reinforcement with wire yourself.

Wire for tying reinforcement cage

The most reliable way to knit a reinforcing cage is using wire. A less successful alternative is the use of a welding machine. The binding of the frame of the base reinforcement can be carried out using ordinary metal wire or wire processed by the firing method. The second option is preferable - thermally hardened wire becomes more flexible and durable.

Wire for tying reinforcement cage

Wire for tying reinforcement cage Calculator for calculating the amount of wire for tying the reinforcing cage of a strip foundation

It is not enough to know how to knit the reinforcement correctly, you still need to carry out the calculation. For this, the following indicators must be taken into account:

- indents between clamps;

- the number of rods of longitudinal reinforcement;

- base length;

- double sealing of corners.

A modern calculator, which you can use online, will allow you not only to determine the amount of wire for tying the frame under the foundation, but also calculate the approximate number of joints.

Rebar tying tools

A reliable frame is an important element of the foundation and the building as a whole. To enhance it, you need to use certain tools. Depending on the choice of the method - manual or automatic, special devices are selected and used.

These tools include:

- manual or semi-automatic hook;

- automatic pistol.

Manual wire crochet hook

Manual wire crochet hook Using these tools, you can knit reinforcement under the strip foundation. An automatic pistol is used in professional construction, as its cost is quite high. For the construction of one building, the purchase of this device is considered impractical. For independent work, the usual one is suitable.

Reinforcement knitting techniques

At the moment, there are four main methods. The most convenient and fastest way is to take the wire, fold it in half and hold it under a certain section of the frame. Armed with a hook, thread the wire into the loop, pull its free end and put it on the hook, while the wire needs to be slightly bent. We twist the ends, after several turns (3-5) we stop the manipulation by removing the hook.

The next technique is similar to the previous knitting method. The main difference is in the formation of an O-shaped loop. After the wire is securely twisted, the hook is removed.

Algorithm for the third reinforcement knitting scheme for strip foundations:

- we start the wire under the rods;

- insert the hook into the loop and pry on the end of the wire;

- we bend it back and pull it towards ourselves;

- scroll several times.

Reinforcement knitting techniques

Reinforcement knitting techniques According to experts, this is the most convenient technique for beginners.

There is another way to knit foundation reinforcement. As usual, you need to fold the wire in half and bring it under the rods. After that, press it against the rod, and bend the ends towards you. Insert the hook and make a few turns.

Use of additional parts for spatial fixation of reinforcement

When knitting the frame, it is necessary to use additional elements. These include "frogs", U- and L-shaped elements, clamps, fasteners. They allow you to fix the reinforcement, its corners.

It is worth saying a few words about clamps. These are bent products in the form of a rectangle. They are made from rods with a smooth or corrugated surface. Clamps are used for load distribution.

For strapping fiberglass fittings, wire or special plastic clamps are used. The first method is no different from knitting a standard frame (metal). Clamps are an excellent choice for those who are new to tying reinforcement. The cost of products is not much higher than ordinary wire. A hook or gun is also used for reinforcement.

Knitting of fiberglass reinforcement

Knitting of fiberglass reinforcement How to reinforce aerated concrete masonry so that cracks do not appear? For this, it is necessary to correctly select the density and strength of the reinforcement. Also, the reinforcement process itself must be performed in compliance with all requirements.

is divided into three types:

- Longitudinal.

- Transverse.

- Vertical.

Correct reinforcement of walls and corners will allow you to strengthen your structure as much as possible.

Reinforcement of the grillage is carried out strictly according to the project. Despite the fact that it looks like a strip foundation, the laying technology is significantly different.

Strong enough, lightweight, practically does not corrode. However, it has significant disadvantages, among which are low elasticity and heat resistance, a decrease in strength over time, and instability to alkalis.

Many people ask themselves the question: huh? Yes, we do. It allows you to make the floor even and more durable.

Is another species that you may encounter. This is a separate way of connecting rods. It can be crimped and threaded. This connection allows you to withstand the loads on the base.

Building a house begins with laying the foundation. The main requirement for a concrete foundation is its strength. It is achieved by laying a frame made of reinforcement rods tied together inside the concrete. Such a frame is called reinforcing. This article will discuss such an important stage of construction work as strapping reinforcement for the foundation.

First, it is necessary to consider what methods of mating reinforcement for the foundation exist in general. They differ in type:

- tool;

- material;

- mating patterns;

By instrument type- it can be either knitting reinforcement for the foundation manually or using a special tool. As the latter, special crochet hooks, screwdrivers, special pistols, produced just for this operation.

As material, which is used to connect the reinforcement rods to each other used:

- knitting wire- This is the most common and reliable technology for knitting reinforcement for the foundation, because it is performed with tying a knot.

- paper clips- are wire tacks, which, unlike tying with a knitting wire, are performed without knot tying.

- clamps small size made of plastic- This new material has become widespread due to the ease of installation and high knitting speed, moreover, it is not afraid of corrosion. However, such a bundle of reinforcement for the foundation causes some skepticism among professionals. Read more.

- clips- made in the form of latches fixing adjacent rods to each other.

- welded joint- this old method did not become widespread, since the welded joint, due to its fragility, is susceptible to cracking during pouring with concrete and does not have the necessary reliability. To make a high-quality welded joint, you need a highly qualified welder.

Required wire

When choosing a wire, the following factors must be considered:

- Manufacturing accuracy class. The accuracy class is determined by the manufacturing method. There is a wire of a higher accuracy class, its deviation of the actual size, diameter, from the declared by the manufacturer along the entire length of the wire is less than that of the wire of a lower accuracy class. However, for knitting reinforcement, the accuracy class does not really matter.

- Wire rolling method. There are two types of rolled products: cold rolled and hot rolled. Cold-rolled steel is rolled out of billets by presses without heating. In the hot-rolled method, the rolled steel is rolled out in a hot state, which gives it greater strength.

- Which tensile strength group belongs to wire (the first and second groups exist);

- Corrosion resistance grade. On this basis, there is only one difference - whether there is a galvanized coating on the wire or not.

The criterion for choosing a wire is very simple, you need a wire, which is called so - "knitting"... It has a full set of necessary characteristics: sufficient softness with the stated strength, abrasion resistance and reliability when fastened.

The criterion for choosing a wire is very simple, you need a wire, which is called so - "knitting"... It has a full set of necessary characteristics: sufficient softness with the stated strength, abrasion resistance and reliability when fastened.

Galvanized wire is considered overkill.

The optimum diameter of the knitting wire is 1.2-1.4 mm. A lot of effort is spent on a wire with a diameter of 1.6-2 mm, as a result of which the construction slows down, and the unit is too weak, it will simply burst.

Carefully care must be taken that the connection of the reinforcement remains rigid after tying the knot: during pouring, the frame must remain motionless. This will ensure the reliability of the structure after solidification.

You need to check the rigidity of the reinforcement connection by touching the rods - if they are rigidly fixed, then they will not walk, which means that everything is in order. You should not try the knot itself for strength, otherwise there is a risk of loosening the knitting.

Recommended wire length for one tying point is 30 to 50 cm. The wire itself is extremely cheap - about 50 rubles. over 100 meters. To avoid its shortage at the wrong time due to loss or excessive consumption, it is recommended to buy it with a double margin. 100 rubles for 200 meters is quite inexpensive.

How to bend the reinforcement correctly, all the ways

The choice of how to bend the reinforcement for the foundation should be based on its diameter: do it yourself it is quite easy to bend a small diameter, but for thicker reinforcement you will have to use special devices, homemade or specialized.

Among homemade devices, two methods are common. The first is when an ordinary pipe of a suitable diameter is installed vertically and its base is poured with concrete so that it stands firmly.

The reinforcement is inserted all the way inside, and now the end protruding from the pipe can be bent by simply leaning on it. If this presents certain difficulties, then a second pipe is additionally put on the free end of the reinforcement, and now, due to the increased lever, the thick reinforcement is quietly bent.Welding is also often used. By softening the section of the rod by heating, it becomes easy to bend it. The same is done with a blowtorch and a hammer. Heated the bending point with a lamp, bend the armature with a hammer.

The most radical way is to make an incision. with a small grinder and then bend completely with the help of improvised tools.

It should be noted that the methods with the use of welding and notches are not the best - in the place of the bend, in these cases, the strength of the reinforcement decreases to 10%.

Crochet

The execution of the hook for these purposes may be different, this is not so important. The point is in the presence of a hook as such, because with it the wire is threaded. The rules for knitting reinforcement for the foundation are schematically shown in the figure.

The execution of the hook for these purposes may be different, this is not so important. The point is in the presence of a hook as such, because with it the wire is threaded. The rules for knitting reinforcement for the foundation are schematically shown in the figure.

Pay attention to the sequence of actions:

- Bend the wire in half;

- In the direction of the arrow, as in the figure, bring it to the threading position;

- Slide the hook into the loop that will now start;

- Pass the loop with the hook inside between the free ends of the wire;

- Without removing the hook, twist until tightened, but do not pinch;

- Ready!

There are mechanized screw hooks in which the wire is tightened by turning a screw. It turns out very quickly and conveniently.

For strip foundations

Reinforcement of the strip foundation has two schemes for laying the rods:

Reinforcement of the strip foundation has two schemes for laying the rods:

- system of 4 rods: two at the base of the foundation, two at the top (used if the width of the foundation does not exceed 50 cm),

- system of 6 rods: an additional longitudinal rod is placed between the two main ones (used in cases where the width of the foundation is more than 50 cm).

Bent reinforcement is laid at the corners, and the ends should protrude at least 40 cm from the corner. Reinforcement joints should be spaced apart at a distance of no more than 60 bar diameters... For example, if 12 mm reinforcement is used, then the strapping should be every 72 cm or more.

For columnar

This is a foundation that is placed on pillars that act as piles.

A tied one is placed inside the pillars before pouring. The reinforcement strapping for a columnar foundation is the same as for a strip foundation - either 4 rods or 6 for large columnar foundations.

For vertical rods in this type of foundation, 12 mm reinforcement is used, since this is a vertical foundation. The transverse rods can be thinner and smoother.

For wooden houses, it is allowed to use longitudinal and vertical reinforcement thinner than 12 mm. Sometimes for the foundation of small wooden buildings, a welded frame is constructed from vertical rods tied with hoops like a barrel. This is wrong, because with this method of bonding, only welding can be used, and this is not a completely reliable method. We have already talked about this above.For slab

A frame made of reinforcement for the foundation can be in the form of a two-dimensional plane, a mesh formed from reinforcement rods. The second option is three-dimensional, in the form of two nets of intersecting reinforcement, located one above the other and connected by transverse bars.

A frame made of reinforcement for the foundation can be in the form of a two-dimensional plane, a mesh formed from reinforcement rods. The second option is three-dimensional, in the form of two nets of intersecting reinforcement, located one above the other and connected by transverse bars.

Fittings - from 12 mm and higher, up to 16 in private housing construction. The mesh size is 200x200 mm. The distance from the lower reinforcement belt to the cushion (or insulation) is 50 mm. The top chord is also protected from external influences with a 50 mm layer of concrete.

Cost calculation (price for work and materials)

Take, for example, a strip foundation of 10 meters by 10 meters. This is the perimeter of the house. In addition, there will be a foundation for the internal load-bearing walls - two walls 10 meters each. It turns out 60 rpm. foundation.

How much knitting wire is required with the right approach?

Let's say the foundation is less than 50 cm wide - it will use a scheme with four longitudinal rods. In this case, in 1 running meter of the foundation, the following will be used:

- 4 longitudinal rods. So at 60 lm. will be 240 meters.

- 4 vertical. With a foundation height of, say, 50 cm, their height will be no more than 45 cm.

4 x 45 cm = 1.8 m. 60 meters of the foundation - 108 m. - 4 transverse. With a foundation width of 45 cm, the width of the transverse ones will not exceed 35 cm.

4 x 35 cm = 1.40m. 60 meters of the foundation - 84 m.

How much is it?

For longitudinal rods, we use 12 mm reinforcement at a cost of 25-30 r / m. 240 x 35 (30) = 6000 (7200)

For vertical and transverse rods, we take 6-8 mm at a cost of 12-16 r / l. (108 + 84) x 12 (16) = 2304 (3072)

So, the purchase of reinforcing rods for this foundation will cost from 8304 to 10,072 rubles.

Now let's calculate the required amount wire. 4 ties for a 4-rooted foundation for 1 lm. This is, based on a maximum flow rate of 50 cm per tie, 2 meters of wire per meter of structure. We have 60 meters, respectively, we need 120 meters of wire.

Attention: wire is sold in kilograms. It is necessary to convert from meters to kg.

1 m of wire with a diameter of 1.2 mm weighs 9 grams, respectively, 120 m of wire with a diameter of 1.2 mm weighs about 1 kg, which costs about 50 rubles. The wire is cheap, so it can and should be taken with a double margin of -240 meters for 100 rubles. It remains to calculate the cost of installation and knitting of the frame. As a rule, it is not calculated separately and is included in the total cost of foundation pouring. In the regions, such works are cheaper, but the price difference is approximately the same - 1000-2000 rubles per cubic meter. This price includes the installation of the trench, the installation of the formwork, tying the frame, pouring concrete and removing the formwork.

The total length of the foundation we are calculating is 60 meters, width 0.4 m, height 0.5 m. Let's calculate the volume: 60 x 0.4 x 0.5 = 12 m3. With such a volume, the cost of foundation work will be 12,000 - 24,000 rubles.

Useful video

How to knit reinforcement in the video below:

In contact with