Stages of building a brick house. Building a brick house with your own hands - the pros and cons of technology. Principles and tools

Living in a private home is an attractive prospect for many people. Purchasing a finished house or building plot is associated with the desire to make your dream home a reality. At the same time, some of the future homeowners entrust the performance of all work to professionals. The rest seek to put a piece of their soul into the house at all stages of its construction. In addition, building a house with your own hands is often cheaper than buying a ready-made one or contacting a developer.

For those who are interested in building a brick house with their own hands, this article will be useful. Here we will focus on the key stages of building a brick house, starting with design, choosing the material for the walls and ending with finishing and cladding. But, first, let's look at what a brick house is good for.

Brick house - advantages and disadvantages

Advantages of brick houses:

- time-tested reliability. Most of the old houses are built of brick;

- strength. It is determined by the brand of brick and its composition (see "GOST 24332-88 Brick and silicate stones");

- satisfactory thermal insulation;

- the microporous structure of the brick allows the house to breathe;

- the possibility of combining with all known building materials;

- multi-storey. You can build a one-, two-, three- or more-story house;

- relative accessibility;

- a variety of types of ordinary and front bricks, which allows you to implement projects that are unique in beauty.

Cons of a brick house:

- price. Building a brick house is expensive. The use of porous bricks allows to reduce the cost of work by 20%;

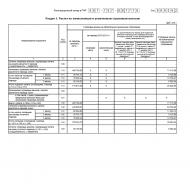

- seasonality. Brick laying is carried out in the dry, warm season. The dependence of the temperature of the solution on the ambient temperature is given in the table;

- the severity of the structure. It is leveled by arranging the foundation of the appropriate type.

Preparatory work

Design of brick houses

There are two ways to get a brick house project:

- choose a solution. Ready-made projects will reduce the risk of errors in the development of the plan. But, even the acquisition of a finished project does not eliminate the need to carry out additional calculations and surveys of the area. Schemes of some of the typical projects are presented in the photo below;

- creation of an individual project of the house. In this case, you can develop a project of a beautiful house that will satisfy your needs to the maximum.

When creating a project on your own, you need to evaluate:

- their financial capacity;

- types of work that you can do with your own hands;

- professionalism and reputation of those who will be involved in the implementation of certain stages of construction (if necessary);

- the complexity of settling formalities related to private housing, communications, water supply, heating, etc.

Stages of building a brick house with your own hands

Brick selection and quantity calculation

Brick can be divided into two types - simple, and facing. In order to reduce the cost of building a brick house, its box and partitions are built from simple brick, and for cladding they acquire a front one.

In addition, the brick is divided into solid and hollow. The first is used for the construction of load-bearing elements of the building. Hollow - to reduce heat loss. Its use reduces the load on the foundation and construction costs.

In addition, the brick is divided into solid and hollow. The first is used for the construction of load-bearing elements of the building. Hollow - to reduce heat loss. Its use reduces the load on the foundation and construction costs.

What else to look for when choosing a brick?

For indicators such as:

For indicators such as:

- water absorption,

- frost resistance,

- thermal conductivity,

- strength (mark M50 indicates that the brick will withstand 50 freeze / thaw cycles).

And also on the color, geometry and integrity of the brick. A solid color will indicate that the brick is made in accordance with the requirements.

How many bricks do you need for a house?

The material was prepared for the site www.site

Advice. The horizontal waterproofing of the foundation of the house is laid twice. The first layer is between the foundation and the plinth, the second is between the plinth and rows of bricks.

If the foundation is incorrectly selected or filled with violations, deformations shown in the diagram may occur.

Brickwork walls

Before you start building brick walls, you need to decide which type of brickwork to choose.

Popular types of brick laying:

With this scheme, you can use a metal mesh for additional bandaging of the rows. It is laid in 5-7 rows and is designed to increase the rigidity of the structure.

With this scheme, you can use a metal mesh for additional bandaging of the rows. It is laid in 5-7 rows and is designed to increase the rigidity of the structure.  Brick masonry. Inside such masonry, voids are usually left, which can then be filled with expanded clay or foam. Thus, the thermal insulation properties of ordinary bricks are increased.

Brick masonry. Inside such masonry, voids are usually left, which can then be filled with expanded clay or foam. Thus, the thermal insulation properties of ordinary bricks are increased.

First of all, brick is laid at the corners of the bearing walls. Not only the appearance of the structure, but also its durability depends on the quality of their installation. The formation of corners involves laying bricks with a height of 5-10 pieces. The correctness of the vertical laying is checked by a plumb line. Horizontally - level. The more often the check is carried out, the less likely it is to skew.

Advice. You can set the horizontal for the entire row using a mooring cord. It is attached to the corners and moves as the subsequent rows of bricks are laid.

As work progresses, the corners are raised.

As work progresses, the corners are raised.

When laying brick walls, it is important not to forget about dressing. For greater strength, each subsequent row should be shifted by half or a third of the brick in relation to the previous one. And also that load-bearing walls must be connected to internal partitions, for this, bricks are removed from the load-bearing wall to the inside.

Brick wall laying - instructions

- cement mortar for bricklaying is mixed to achieve greater plasticity;

- the solution is applied to the right place and leveled. In this case, part of the solution is displayed on a brick located in a row. If the solution is more than needed, then the excess will simply be removed with a trowel;

- a brick is laid on the mortar. For a tighter fit of the brick in a row, they knock on it with a trowel handle. The optimal distance between rows of bricks is 12 mm;

- the last brick in the row is being laid. It is good if the bricks are laid whole or in halves. But, in practice, this is rarely the case. You can get out of the situation as shown in the photo.

In the first case, the gap between adjacent bricks was regulated by the thickness of the mortar, and in the second, brick pieces were used. The choice is yours.

In the first case, the gap between adjacent bricks was regulated by the thickness of the mortar, and in the second, brick pieces were used. The choice is yours.

- after the row is completed, the brickwork is grouted.

Advice. If the surface of the wall will be faced with plaster, then it is advisable to leave a little free space in the seams. If the work is done immediately with the front brick, then the jointing must be done beautifully, filling the entire space.

Jointing brick joints is done with a special tool.

Jointing brick joints is done with a special tool.

Window and door openings in brick walls

During the construction phase, the installation of window and door openings is envisaged. To do this, voids of the appropriate size are left in the walls.

When the planned opening height is reached, a wooden, metal or reinforced concrete lintel should be laid. The width of the jumper is equal to the thickness of the wall. In length - 40-50 cm should exceed the width of the door / window opening. This is due to the fact that for the reliability of the installation, the jumper should go into the wall by 20-25 cm. Rows of bricks will be laid on it in the future.

Advice. When using a wooden jumper, it is necessary to protect its ends with roofing material and treat with a primer. The metal jumper also needs to be treated to prevent rust.

After that, the rest of the bricks are laid until the specified wall height is reached.

At the top of the load-bearing walls, interfloor or attic floors are installed. They can be slab, monolithic or wooden.

Roof of a brick house - roofing work

The roof device includes:

- project development and choice of roofing material. It is depending on the choice that the calculation of the material, the cost and complexity of the work will be carried out;

- installation of a truss system. In the vast majority of cases, a wooden beam is used to perform this type of work;

- framing installation. Its step depends on the type of roofing material. So, for slate, the pitch is 70-80 cm, for metal tiles 35 cm, and for bituminous tiles, a continuous sheathing of plywood or OSB is required;

- roof waterproofing;

- laying of roofing material and installation of decorative elements;

- insulation and vapor barrier (if necessary).

Installing the roof will give the house a finished look and will allow you to carry out further work in any weather and at any time of the year.

Construction of interior walls

It is performed in the same way as the external device, so we will not dwell on it.

Installation of windows and doors

Most often, doors and windows are purchased ready-made. Their installation also remains on the conscience of the manufacturer. But if you are interested in installing windows / doors in a brick house with your own hands, then this can be found in the appropriate section.

Laying communications

Engineering communications, heating pipes, electrical wiring are also an important component that is necessary for the full functioning of the house. Each of these aspects deserves more attention. After all, the implementation of such work requires certain knowledge and skills.

Advice. Don't forget to protect your home from lightning.

Floor device in a brick house

You can lay floors in a private brick house in the following ways:

- wooden floor on logs;

- floors on the ground (wooden or concrete);

- floors on floor slabs.

Insulation of a brick house

An important aspect that must be taken into account when building a brick house, because the brick itself transmits a lot of heat. In order not to heat the air, you need to take care of the insulation. Popular thermal insulation materials include: basalt wool, polystyrene foam, polystyrene foam.

Brick is the leading building material. The service life of a brick house, subject to the construction technology, can exceed a century, and the construction time, using modern technologies, is a matter of weeks. We will talk about how to build a house out of bricks, as well as the pros and cons of brick houses in this article.

There are many varieties, sizes and types of this building material. Building bricks are used to form walls, piers, and other structural elements. The surface is rough, with chips, spots and color transitions.

Facade or facing clinker bricks are used as the main material for finishing work on the facade of architectural structures. In addition, it can be used to create original design installations inside various rooms. Let's figure out which brick is better for building a house.

Types of bricks by type of clay

ceramic brick

Ceramic bricks are used for construction purposes and as cladding. The material is made from red clay by firing. Materials that do not have worthy aesthetic characteristics are used for the construction of walls, arches, partitions. Brick with decorative relief allows you to create an original decor for a barbecue oven, decorate a fireplace or simply decorate a wall.

Refractory brick

Refractory brick differs from ceramic in that it is able to withstand the strongest thermal loads. It is made from refractory clay, firing more than 1300 degrees. It has a low level of thermal conductivity. It is resistant to temperature fluctuations. This is an ideal basis for creating heating structures.

silicate brick

Silicate brick is made from lime, which gives the material a special strength. This is the most common type of building material for building a house, as it has good mechanical properties and a low price.

Types of bricks according to design features

A solid brick is equipped exclusively with holes of technological origin and consists of 83 - 91% of clay. Advantages of this type: strength, ability to withstand heavy loads. The walls of multi-storey buildings are built from this building material.

Hollow, or as it is also called effective brick, has special holes (from 10 to 45% of the volume). It can be square or rounded with through or non-through voids.

Holes can improve the heat-shielding properties of bricks, save raw material consumption in the production process, and simplify some stages of the technological process. This material is quite light, does not overload the foundation of the structure.

The audibility in houses made of hollow elements is much lower than in houses made of solid bricks, since the voids are also soundproofing.

Super efficient brick

Ultra-efficient or porous brick has the highest properties for high-quality thermal insulation and in terms of audibility. Manufacturers add wood sawdust or expanded polystyrene to the clay batch, which, under the influence of high temperatures, burn out and leave closed voids behind them. The products are very light, even despite the fact that their dimensions are significantly larger than those of other types of building materials.

All brick sizes for landscaping and construction are standardized. There are three main types of this building material:

- Single (250x120x65 mm);

- One and a half (250x120x88 mm);

- Double (250x120x138 mm).

These dimensions will be useful to you when calculating the number of bricks for building a house. Having calculated the quantity, based on the dimensions of the building, you can calculate how much it will cost to build a brick house.

How to build a brick house

Let us briefly outline all the stages of building brick houses. Before the start of construction, a foundation is erected under the load-bearing walls, which can be block or monolithic. To figure out what kind of foundation is needed for a brick house, we recommend reading an article about ). Then the tasks associated with are solved and only then proceed to the very laying of load-bearing walls and partitions.

The thickness of the brick walls varies depending on the features of the project, the purpose of the house, as well as the presence or absence of insulation. As a rule, the thickness of the partitions is chosen in the range of 120-250 mm, and the thickness of the bearing brick wall is chosen from 380 to 510 mm. In modern buildings, the load-bearing wall pie consists of one and a half to two bricks, a layer of insulation and masonry of facade bricks 120 mm wide.

Before laying, make sure that the foundation is absolutely level. To do this, check the measurements for slope, verticality, horizontality. There are the following schemes for laying building bricks:

- Chain type of masonry with dressing of seams in each row;

- Simple brickwork with continuous seam dressing;

- Lightweight type of brickwork with the addition of insulation.

Below is a small infographic with the main types of brickwork:

We also offer a look at the process of masonry brick work.

Insulation of brick houses

Insulation of external walls is an important stage in construction, which can significantly improve the operational properties of the building.

For the insulation of architectural structures made of bricks, mineral wool or polystyrene is used. Plaster is applied over the “fur coat”, fixing the heat-insulating layers, giving the building an attractive appearance. Of the latest innovations, the “wet facade” is popular, which combines the functions of insulation and decorative finishing of external walls.

From the competent installation of insulation depends on how much home owners can save on heating in winter and reduce energy costs for air conditioning in summer. Distinguish between external and internal type of insulation. Often use the first option, which is less expensive and convenient in practice.

The disadvantage of brick houses compared, for example, with buildings made of , is the presence of a large number of cold bridges in the form of seams in brickwork. This can result in increased heating costs for your home. To avoid this, you do not need to save on additional insulation.

How to finish a brick house outside

Now let's deal with the issue of exterior decoration of a brick house. For decorating a brick wall, the most ordinary plaster is suitable. The master will be able to achieve both unusual relief and an absolutely smooth surface. This finish improves the fire resistance of the structure, positively affects the soundproofing qualities. To finish the basement, plaster is used less frequently.

The outer side of a brick wall is often decorated with natural or decorative stone. It looks very solid and respectable. This material is very strong and reliable, capable of retaining its original appearance for centuries. In this case, the plinth is best decorated with natural stone.

Another popular type of decorative brick wall decoration is modern thermal panels. The facade is particularly dense, looks aesthetically pleasing and elegant. A special advantage is that the thermal insulation properties of the house are improved several times.

Pros and cons of a brick house

Let's summarize all the advantages and disadvantages of brick buildings. The advantages of brick houses are:

- Durability. Brick building is considered to be one of the most durable. The service life of such a house can reach several centuries, since this material is not subject to decay, like.

- A brick house retains its original appearance for a long time, so additional external finishing of such structures is not always required. Brick itself is a good finishing material.

- Nowadays, the loft style has become widespread, which involves the use of natural brickwork as an interior decoration. Therefore, when building a brick house, you can save on interior decoration.

- Fire resistance. Brick walls are non-combustible, so in this component they outperform houses made of logs or timber, as well as frame buildings. Often this advantage is decisive when choosing.

- Strength. Brick walls are among the most durable in private construction. They withstand significant loads from the roof, and also allow the construction of multi-storey buildings.

- Environmental Safety. For the production of bricks, only natural materials are used - sand, clay and water, which do not emit harmful substances into the atmosphere.

- Frost resistance. Brickwork withstands many more freezing cycles than aerated concrete, so such houses can stand without exterior finish in aggressive conditions for hundreds of years.

The most frost-resistant type of brick is clinker brick, which is often used on the outer layer for building cladding. - Investing in a brick house is a good investment, as this building material has proven itself in all respects.

A few decades ago, brick had no competitors, but with the advent of new building materials on the market, the disadvantages of brick houses became obvious. Let's analyze the main ones.

- High material cost. Brick is not the cheapest building material, so not everyone can afford to build a brick house and choose cheaper analogues, for example.

- The need to attract masons for laying the house. The construction of brick walls is not an easy task, therefore, hired workers of the appropriate qualification are often involved in such work. The work of masons is paid quite high.

- Terms of construction of a brick house. The construction of a building from this building material is slower than using more modern construction technologies. As a rule, it takes several months to build brick walls. True, in comparison with wooden houses, brick ones do not have significant shrinkage, which allows finishing immediately after the construction of the box and bringing the house under the roof.

- Due to the heavy weight of a brick house, it requires a heavy monolithic foundation. Such a foundation will cost much more than for light buildings made of wood or.

- To ensure sufficient heat capacity of a brick wall, it must have a significant thickness. This increases the consumption of materials and estimates for construction. Houses made of modern building materials with the same heat capacity have a wall size many times smaller than that of brick buildings.

A brick house is perhaps the most durable and adapted to our weather conditions. It contains many positive qualities, such as strength, long service life, energy intensity and fire safety. In addition, the disadvantage will be the need to attract specialists for construction, as well as the need to equip a strong foundation.

At the end, we suggest watching a short video with the calculation of the cost of building a brick house

Considering the average climatic indicators in all regions of Russia, brick is an ideal option for building a house. This is evidenced by a number of undeniable advantages, such as strength, durability, resistance to various precipitation and seismic vibrations. Having correctly approached the construction process, it is quite within the power of any master to build a brick house from the foundation to the roof.

A brick house is always reliability and quality.

Where does construction begin?

Any construction begins with the receipt of permits. Then, there is a design, where options for connecting communications are considered. All this is fixed in the plan for building a house. Geological exploration is carried out on the spot to determine the type of soil. This is necessary to determine the type of foundation. Although for a brick house, in any design, it is recommended to fill in the tape base. But still, reconnaissance of the area is necessary to identify groundwater and depth from the passage. According to the data received, you will know how deep you need to dig a trench under the foundation.

Foundation for a brick house

Whatever the arguments are, in favor of foundations on piles or concrete pillars, the best option for a brick house is only a tape-type foundation. Reliability and low complexity of execution simply leaves no chance for other types of foundations. The tape is located under all load-bearing walls and some partitions. The width of the foundation must be 15–20 cm more than the thickness of the walls. A set of tools and materials for laying a strip foundation for a brick house is as follows:

- to prepare the mixture, cement, sand and aggregate in the form of gravel or crushed stone of the middle fraction are needed;

- roofing material or any materials produced from it, for waterproofing the base;

- to raise the formwork above the ground, you will need unedged boards or plywood;

- reinforcing bars;

- mixer, containers, shovels, theodolite and any device for "removing" air from the thickness of concrete.

Schematic drawing of a strip foundation.

At the construction site, the soil is cleared of foreign objects. The top layer of the earth is removed by 10 cm along with the turf. Further work is carried out according to the situation. If a basement is planned in the house, then a foundation pit is dug, to a depth below the freezing level of the soil. If such construction is not provided, then only a trench of the appropriate size is prepared. When working manually or with hired equipment, it is necessary to monitor the evenness of the corners so that the foundation slab is without distortions, which will subsequently affect the evenness of the brickwork. The depth of the trench or pit for the basement or basement should be the same.

Depending on the type of laying the tape base, and there are two of them: monolithic and prefabricated, further work is also carried out according to plan. When pouring cement mortar, the bottom of the pit is first covered with a sand-cement cushion, watered, compacted and covered with waterproofing. Preparation ends by pouring a small layer of mortar.

When laying the prefabricated base, the same manipulations are performed, with the difference that the pillow is laid at the place where the plates are installed. This is a more complex version of laying a strip foundation, and for its implementation, special equipment or at least five people will be needed. Blocks are installed in a trench and connected with a concrete mixture.

Formwork with reinforcement and supports for reinforcement.

The formwork is necessary to raise the base tape above the ground. This will protect the brick from moisture transmitted from the soil. Concrete in this case is more resistant, moreover, the base is waterproofed after laying. Of all types of foundation for a brick house, the tape base more reliably protects the brickwork from moisture. Formwork is assembled from two sides, on both sides of the trench. So that the sides do not break the concrete during solidification, it is fastened on top with wooden lintels, after 30–40 cm.

Now the frame is next. To create it, reinforcement with a cross section of 8 to 10 mm is required. The rods are cut to such a length that, when installed in a trench, the metal head does not protrude above the formwork surface, but is 5–10 cm below it. pre-laid bricks.

It remains only to pour the solution. If it is not possible to prepare the amount of concrete for a one-time pour, laying in several layers is allowed, only they should be no more than 20 cm, with each exposure until completely solidified. At this stage, the laying of communications supplies from the outside to the inside of the house and the drainage of sewage from the inside to the outside are organized. In places where pipes exit, metal sleeves are installed. After pouring the last layer under the formwork, the surface is leveled, bayoneted with fittings to release air gaps, covered with roofing felt and left for a month until completely dry. When the base gains strength, you can proceed to the next work.

Formwork can be removed after 10 days after pouring.

Building walls right

When building a house for permanent residence, the thickness of the walls must be calculated at least two bricks. And experts consider well masonry to be more rational in terms of reliability and reduce heat losses. A kind of multilayer system. The brick is laid in two rows with the installation of insulation between them. This allows not only to reduce heat loss, but also the load on the base. The appearance of a brick house should be at its best, even without additional finishing, so you need to choose the right brick for construction. The stone is only flat, with right angles.

Option for well masonry bricks.

You need to start building walls by raising the corners. For beginner builders, this is the easiest option that allows you to evenly lay out the masonry. In order to avoid troubles, such as breaking stones or shifting the wall horizontally, here you need to show maximum attention and patience. When laying, the stones should, as it were, “look” at each other in both planes. Raising the corners by 4–5 stones, twine is pulled between the corners for subsequent work. It will allow you to control the horizontal. But first, the height of the corners is checked by the level. Small differences can later be leveled by laying more mortar.

Having prepared an impromptu level, bricklaying continues. You need to know at least an elementary dressing technique in order to create a stable wall. Principle of chess. Bricks from each subsequent row are shifted by 1/2 - 1/3 of the stone laid in the previous row. To start knitting, the first brick from the next masonry is cut in half with a grinder. In places where door and window openings are installed, the brick is laid in a bonded way, across the entire width.

In order not to disturb the evenness of the masonry, distribute the solution evenly. Also, a small amount of the mixture must be put on the end part of the already laid stone, and putting the next one, by tapping the trowel on the surface, trim it in the plane. Having laid out all the rows to the raised corners, it is necessary to make a dressing. Reinforcement or metal mesh is needed. It is laid out on the surface of the finished row and laid next. Further work is carried out in the same mode, preliminarily raising the corners, hanging the twine and continuing the laying along the stretched line.

A stretched rope allows you to focus on the evenness of laying bricks.

Finishing - worth it or not?

Using a smooth ceramic stone for laying walls, additional processing or decoration will not be necessary. If you plan to plaster the surface, then try to rationally use the solution. It is not necessary to allow it to protrude beyond the brick when laying. Subsequently, you will have to chip off the excess to cover the surface with plaster. Such manipulations can be avoided when finishing exterior brick walls with siding. . But still, accuracy is useful when laying facing stone. To make the seams neat, trim them with a trowel after laying.

Roof of a brick house

Here, complete freedom of imagination is allowed. Brick walls are reliable, and when laying a solid foundation, this quality increases several times. Therefore, it is allowed to model the most complex system, up to structures with attic rooms. But if we are talking about building a brick house, then it would be more appropriate to talk about a gable roof with a pediment made of stone. There are two construction options here: in the process of building walls and after laying the rafters.

The brick pediment, laid out during the installation of the walls, is additionally strengthened before laying the rafters so that the winds and the weight of the wooden floors do not destroy it. Additional support is created by laying a transverse wall or pilasters inside the attic. It will be easier to do this when laying reinforced concrete floors in a brick house. Internal partitions must be at least 25 cm thick, that is, laid out in one brick.

Usually, the design and laying of the rafters are adjusted to the gables, if its installation was carried out before their installation. In another version, after assembling the structure, closing the end span, one can make annoying mistakes in geometry. Simply put, the pediment will not be fully combined with the truss system. Such flaws can be hidden with wooden plumb lines, but in the future this will lead to a skewed roof.

When laying the gables of a brick roof, it is much more convenient to hem the structure.

In the variant with pre-installation of rafters, it is necessary to put a Mauerlat along the load-bearing walls. This is a kind of basis for rafter legs. Again, there are some adjustments when building a brick gable. Mauerlat does not fit on all walls, but only on both sides. Before laying the foundation for the rafters, a reinforced belt is poured along the top of the wall. It is necessary to relieve the stress exerted on the Mauerlat. Actually, this is what needs to be done during the laying of walls for the subsequent installation of the roof structure. . The reinforced belt prevents tensile forces that create a load on the Mauerlat, from which it can move to the side and “lead” the rafter legs, and, as a result, the entire roof structure.

Considering further the option of preliminary construction of a brick pediment, we proceed to the following works. The ridge beam is mounted from the upper points. Rafters are stuffed down from it. Their length in any case should be 20-30 cm below the wall. Such an overhang will protect the walls from precipitation. At the edges, the rafter legs are connected with a crate, which is subsequently stuffed over the entire area of the roof. The distance of laying the board is selected according to the type of roofing material. Usually it is no more than 20 cm. By laying the rafters, an overhang is organized over the gable. There are no difficulties in the work, just the boards are stuffed on supports with a ledge beyond the wall.

When building brick houses, there are no restrictions on the choice of truss structure.

If the option of pre-assembling the roof is used, followed by laying the pediment with bricks, then the last work will be carried out in conditions of limited access. But depending on the type of roof structure of a brick house, there may not be such inconveniences. For example, a hip roof has a free attic space. Depending on the angle of the gable roof, when choosing such a design, there may be no problems with laying the gable.

Summary of work

After the construction of a brick house under the roof, other related work is carried out. These include insulation, walls, if necessary, waterproofing of the roof and its insulation, summing up communications and internal arrangement. In general, it is possible to build a brick house from the foundation to the roof on your own within one year. Someone fits in a shorter time, but still there is no need to rush in this matter. The base must gain strength and shrink brickwork.

Many are now interested in how to build a brick house with their own hands. Brick is one of the most durable materials, so such a house will stand for more than one hundred years. However, it is very expensive, so the construction will require significant costs.

Own brick house has long been considered a symbol of prosperity and respectability. Where to start construction, and how to make it as profitable as possible?

Project preparation and budgeting

The construction of a brick house can take more than one year, it all depends on the scale of the structure. Work begins with careful planning and a detailed budget to estimate the upcoming costs.

Approximately 20% of the cost of the house falls on the foundation, the price will also depend on the number of floors, the presence of an attic and other design features.

The simplest option is a one-story building erected according to a standard project. It is necessary to determine in advance the dimensions of the load-bearing walls and their thickness. For areas with a harsh climate, laying of 2-2.5 bricks is usually used, this avoids serious heat losses during the cold period of time.

You should consider the location of rooms, corridors, window and door openings. The project reflects the placement of windows and doors, as well as their area, which allows you to correctly calculate the number of bricks.

It is necessary to determine the type and type of roofing and roofing materials, consider options for insulation and interior decoration.

Advice! It is also important to consider unforeseen expenses. Brick is always purchased a little more than it should be, since at least 5% is necessarily spent on battle and marriage.

When all the calculations are completed, you can purchase the material and proceed directly to the construction. It is very difficult to cope with such a task alone and the work can be delayed indefinitely, so it would be wise to calculate options for hiring assistants.

Foundation construction

The foundation is the basis of the house and the guarantee of its durability, and in no case should you save on it. For: a solid concrete slab will be very expensive, and in this case is not justified.

If the soil contains too much moisture, it is pre-drained and carefully compacted.

According to the plan of the house, on a leveled area, the perimeter of the future foundation is marked with pegs and twine. Then a trench is dug under the foundation, the depth of which will depend on the parameters of the soil and the depth of its freezing, as well as on the type and design of the building.

More accurate data can be found in SNiP 2.02.01-83 “The depth of foundations. A layer of sand or gravel is poured to the bottom. A dense base will help the building avoid deformation and cracks during shrinkage.

The foundation is reinforced with a metal frame made of reinforcement to give it increased strength.

Advice! To achieve maximum strength, it is desirable to fill the fill at a time. For these purposes, it is optimal to order the finished mixture with delivery using an industrial auto-mixer.

If this option is not suitable, then a concrete mixer should be used, and several people should carry out such work at once. The top layer of the plinth is leveled with a trowel. The foundation needs time to dry thoroughly, the full setting time of the concrete is about thirty days.

Wall construction

How to build a brick house yourself? Brickwork can be done by hand, but if possible, it is still better to entrust the work to a professional master. This is a rather complicated business that requires experience and skills.

Improperly executed masonry can lead to cracks in the walls and the collapse of the entire house. However, if you are confident in your abilities, independent work will save a lot of money.

Which brick to choose: silicate or ceramic?

It is important to choose the right brick, optimally suited for the construction of walls.

There are two options - silicate and ceramic, both have their advantages:

- Silicate brick is the cheapest option, while in terms of decorative and other properties it is not inferior to ceramic;

- Silicate brick can have different colors, which plays an important role in the construction of a house. Double silicate brick M 150 is convenient for the construction of load-bearing walls, its dimensions allow you to save on the purchase of materials. However, it is not waterproof, so it cannot be used to build a basement;

- Ceramic building bricks have increased resistance to a variety of destructive influences. He will not be afraid of either humidity or low temperatures, it is a very durable material, although it has a high thermal conductivity compared to silicate brick.

It is better to consider all options in advance and choose the material that is best in price and quality. Before laying, a layer of roofing material is laid on the foundation for waterproofing. A control cord is pulled from corner to corner, helping to see a straight line for the correct laying of rows of bricks.

Solution preparation

It consists of fine, carefully sifted sand, clean water and cement grade M400 or M500. For a mortar grade M50, the ratio of sand and cement during preparation will be 4:1. The more sand in the solution, the less durable it will be.

Before work, the sand is sifted through a construction sieve so that there are no pebbles, twigs and other construction debris left in it.

Advice! It is important that the amount of the prepared solution can be used at a time, otherwise it will harden and will no longer be suitable for further work.

The components of the solution in the required proportions are placed in a concrete mixer and mixed until fully prepared, then the solution is poured into a tub and you can proceed directly to the brickwork.

Brickwork walls

Masonry starts from the corners, where several bricks are laid out at once. Then, a solution is laid out on the base in an even layer up to 8 mm thick, and bricks are laid on it.

The first row should be a reference according to the scheme, since the entire subsequent wall will depend on it. The lower rows - the basement of the building - should be lined only with ceramic bricks.

Instructions for laying bricks - basic rules:

- Before work, if the brick is very dry, then it is immersed in water for several minutes. Ceramics tend to absorb moisture, and if this is not done, it will draw it out of the solution, reducing its strength;

- The laying is carried out with strict adherence to the dressing: this is the name of the basic principle according to which each subsequent brick must be laid on two in the previous row. This scheme ensures the strength of the joints and prevents the appearance of cracks;

- With each new row, the corners rise up, they must constantly exceed the main masonry by 4-5 rows. They are constantly checked with plumb bob. The horizontality of the rows is determined using the building level, it is important to ensure that the solution layer throughout the row is uniform;

- The walls must be strictly perpendicular to each other; a construction square is used to check. It is necessary to constantly monitor the correctness of all measurements and control the quality of work.

Bricklaying is a rather painstaking work that requires responsibility and patience. The photo shows what the correct masonry looks like.

- Before installing floor slabs in a two-story house, a bonded row of masonry must be made;

- Reinforcement of brickwork with special meshes every few rows contributes to strengthening the strength. When working, building bricks should only be intact, without chips and cracks.

The video in this article will show the main stages of the construction of brick walls:

Roof in a brick house

As a rule, pitched roofs are used for low-rise buildings, since snow does not accumulate on them in winter, and they last longer. After the walls are completely finished, you can lay the attic floor and proceed to the arrangement of the roof.

Its frame consists of Mauerlat and rafters.

Mauerlat is a support for rafters, a thick beam is usually used, and it is better to lay it around the entire perimeter of the building. Rafters are powerful beams that will later support the roof.

For fixing roofing materials, a wooden crate is used, the pitch of which will depend on the selected coating. If a soft roof is used, then a solid flooring made of plywood or OSB boards is used as a crate.

The roof in a brick house requires additional insulation. First, a vapor barrier layer is located under it, insulation material (most often, mineral wool) is laid on it, and a waterproofing layer is placed on top so that condensate does not accumulate in the attic.

A multi-layer "roofing cake" will allow the building to not lose heat, while in the attic it is necessary to provide sufficient ventilation.

Arrangement of insulated floors in a brick house

The floors in a brick house are very often made of wood, as they are the easiest to insulate. In this case, wooden logs are installed, between which layers of insulation are laid.

Subfloor boards are laid on top, on which any finishing coating can be laid. Laminate, linoleum, parquet can act as such a coating, but in any case, the floor will not be cold to the touch.

If desired, in a country house, you can equip a floor heating system. This is an additional heating and protection against colds in cold weather.

Electric underfloor heating involves laying heating elements under the floor covering. It is comfortable, convenient and safe, especially since the temperature can be adjusted.

Upon completion of construction work, you can proceed to rough and fine finishing. There can be many options here, and the choice will depend only on the capabilities and desires of the owner.

A brick house can serve its owners from 100 to 150 years. It is thanks to the strength and durability that this material enjoys an advantage in the construction market. A variety of colors and shapes will allow you to create various architectural works and turn the house into a palace.

Peculiarities

Construction is a painstaking process that requires precision in execution. For brick houses, both the quality of the material and the laying process itself are important.

A brick house has its pros and cons:

- Energy efficiency. A brick house with walls of 40 centimeters without various heat-insulating materials is competitive with a wooden wall of 1 meter. This indicator allows you to live in warmth in winter and not languish in the heat in summer. It also handles wind and heat well.

- Durability. The minimum term even for the lowest quality brick is at least 50 years. This quality will save you from constant overhauls and replacement of elements, as is the case with wooden houses.

- Convenience. Small dimensions allow you to create complex structures - corners, arches, polygonal walls, loggias. Inside you can make a fireplace from the wall, a stove.

- Diversity. Brick pattern, color range, shape - all these qualities will make your building individual and not like the rest.

- Hygroscopicity. Brick is a porous material. Along with strength, it absorbs moisture, which leads to destruction. The solution to this problem is plastering with mortars with a high cement content.

- Low thermal conductivity. This quality can be a plus in a house with constant heating. But if this is a suburban area and you are not there all the time, then you should expect high humidity, and, as a result, mold. It will not be possible to warm up such a house quickly - it will take a couple of days for the structure to begin to store heat and slowly cool down.

- Heaviness. Brick is a heavy material compared to its counterparts, such as aerated concrete. Therefore, it requires a massive and deep foundation. However, there is salvation here too - silicate brick with a relatively low weight.

- A large amount of plaster for the exterior of the facade, if brickwork or, for example, siding is not provided.

At the moment, the construction market offers two types of bricks for construction:

- Silicate. Lightweight material with large dimensions, which is important when calculating the load on the foundation. It has low thermal conductivity. It is easy to mount, and due to the size it is also done quickly. It's easy to cut. No special tools or tools are required for installation. It is important that such a brick has an acceptable price.

- Ceramic. Dense and strong. It has a beautiful appearance, so it is often used in cladding and does not need additional plaster. Hollow brick has low thermal conductivity. In turn, ceramic bricks are also divided into building and facing. The cladding option has a beautiful structure, because it serves as a decoration and a “cleaner” for your home. The price of ceramic bricks is, of course, higher.

Of the two types, silicate is acceptable. At low cost and a small amount of time, even a beginner is able to build the walls of the house. Ideally, it is better to combine two types - to make the walls silicate, but to make the lining with ceramic bricks. However, the cladding material today is diverse, so the facing brick has a lot of competitors.

This species division is conditional, since building materials today have a wide variety for every budget and taste. To satisfy your desires, you need to explore all the options offered.

Projects

The most important stage, on which the whole construction of the house and its location depends, is, of course, drawing up a plan. Much of this is decided by SNiP (building norms and rules).

Professionals and everyone who has encountered the construction of brick houses are advised to use a project that was developed by people who know the intricacies of the process. This will facilitate the construction process with a minimum of possible errors, and everything related to registration and registration by cadastral services. This does not mean that you cannot use your plan. You just have to be very careful here. Then you will get a house that best meets your requirements.

It is necessary to take into account the layout of the entire territory, because the economy does not end with one house.

The location of the house relative to the neighbor's house should be taken into account, and not the borders, which for brick houses are at least 6 meters. But from the neighbor's border, the house should be 3 meters away, but if the neighbors have no complaints, then the house may be closer. From the red line (a conditional line between your site and the roadway), the house must be at least 5 meters away. You should not neglect the rules, otherwise you will face a fine or even demolition and a requirement to relocate the building.

The plan of a private house takes into account all walls, windows, openings, wooden floors. The standard for construction is silicate brick with dimensions of 250x120x65 mm. It is under it that the thickness of the walls is oriented. In a house with permanent residence, the thickness of the wall must be at least one and a half bricks. An ideal, but very costly option is 2.5. For country houses where residence is not regular and does not provide for winter stay, the wall thickness can be one brick.

It is necessary to determine the load-bearing wall (should go across the entire building), and designate it in the plan, determine the floors and complete the layout of each. House sizes may vary. For a one-story house, the dimensions of 8 by 10 m are optimal, which will accommodate all the necessary rooms. A two- or three-story house can be smaller and benefit from a height of 8 by 8 m.

materials

To build a brick house, the following materials are needed:

- the material of the proposed skin;

- cement - the M-400 brand is suitable for construction;

- river sand;

- slaked lime;

- crushed stone or gravel;

- board, plywood;

- thermal insulation materials;

- fittings;

- wooden floors;

- roofing material or hydroisol;

- plasticizer to increase the elasticity and plasticity of the solution.

Preparatory work

The first thing to do is to prepare the surface, level the area, remove all unnecessary, debris, shrubs. Next, the marking of the site for the foundation begins. It takes into account the external walls of the house. Then, according to the markup, you can start digging trenches.

Then choose the type of foundation and masonry.

foundation type:

- Tape (the most popular). The trenches are lined with bricks or boards and poured according to the tape pattern. Installed under load-bearing walls. Concrete consumption in this case is average.

- Slab. For him, they dig pits and pour the foundation in the form of a slab. Such a foundation is suitable for heavy houses. But with this design you need a lot of concrete.

- Columnar. Support for the house - monolithic pillars, which are poured and connected with transfers. Minus - strong shrinkage.

- Pile. Holes are made with a drill and piles are installed. For such a complex design, special equipment is required.

The higher the house, the deeper the trenches should be. For two- or three-story houses, this figure should be at least 1.5 meters.

The laying of the walls can also be different:

- Standard - in 4 bricks.

- With metal mesh. It serves as an additional material for linking rows. For the necessary rigidity, it is laid in 5-7 rows.

- Well. Masonry to increase thermal insulation. Gaps are left inside the masonry, which are filled with a certain material - expanded clay, foam, cement. Not only thermal insulation increases, but it is also possible to save on bricks.

- Lightweight. With such masonry, a contour is built in the form of one brick of the outer wall and one inner. The gap between them is filled with a solution.

At this stage, the calculation of the number of bricks is also underway. To do this, we calculate the area of \u200b\u200bthe bearing walls (the perimeter must be multiplied by the height). Next, you need to subtract the area of the openings. Then calculate how many bricks will be needed per 1 square meter of wall, given the type of masonry chosen. We multiply this figure by the figure obtained from the bearing walls. To the resulting figure, we add 5-10 percent for fitting or waste.

Before construction, get a mixer for mixing concrete, containers for mixing it, shovels, trowels, level, cord, plumb line, saw, grinder, jointing. All this will allow you to quickly and correctly build the walls of the future home.

How to build with your own hands?

After choosing the type of foundation and masonry, you can begin to build a house.

When installing the foundation, crushed stone (~ 5 cm) is first poured into the bottom of the trenches. So the design will be more durable. Then the reinforcement for the bundle is installed. To save money, you can also use just metal elements, corners, a profile, wire - everything that will help tie the foundation and make it stronger. It remains to pour and leave it to dry. The minimum waiting time is 1 month. Some leave the foundation to harden for a year and start work the following year.

The finished coating is covered with roofing material. In order for the foundation to serve you for many years and the house does not give cracks and deformations, it is important to waterproof the foundation with a special film or composition.

This will protect against moisture, and melt and ground spring water will not get into the basement of the house. When installing the foundation, consider the depth of the basement, sewerage, the location of the toilet and bathroom. For quick access to the basement in the basement, you can make a door.

The next step is building walls. The cement mortar must be well mixed for greater bonding power and to avoid subsequent shedding. The amount of solution should not exceed the speed of the master, otherwise it will simply harden and you will lose the material.

Laying starts from the corner. The solution should fill the entire space (approximate width 1.2 - 1.5 cm). Each brick is tapped to avoid excess air in the seams, and, as a result, rapid destruction. Excess mortar can be removed with a trowel. It is good if the last brick in the row is whole or half. But if this did not happen and there was a gap, then a larger amount of mortar or a piece of brick will help. If you are working with a front brick, then at the end you need to do the jointing from the outside - cleaning the excess mortar and leveling the seam. If this is an inner wall, then you need to leave a small distance between the seams for further filling with mortar from neighboring bricks.

Thus, rows are lined up to various openings - door, window. Here it must be taken into account that the length of a row with an opening can change from ending with one brick to using only a part. You can easily cut it with a grinder. These are voids, the height of which is closed by reinforcement - a jumper. Its width should correspond to the thickness of the walls. The length should, of course, be 20-30 cm longer than the opening, and be fixed on the rows. Further work continues as usual. Then comes the construction of the inner walls. Their laying should go from the bearing walls, if brick walls are meant in the house.

The next stage is the installation of floors (anchoring) - interfloor, roofing, attic. The role of the floor can be a slab, wooden beams. They must be embedded in the walls. Anchoring involves the complete interconnection of all structural elements of the house and avoids deformations and "walking" of the building.

The technology of the roof device includes rafters - wooden beams, lathing - on which roofing material will be installed, waterproofing, coating, snow retention system, thermal insulation.

Attic walls can be made of brick or other material to save money. This also applies to the walls of the house - facing bricks, siding, block house, plaster and similar materials.

It is important to build a floor for further movement inside. For starters, it can be a draft floor on logs from a draft board. If you do not want to spend extra money, then you can lay the boards directly on the ground. Then you will need to stock up on stairs.

If these stages are passed, then the main part of the load on building a house is over. Now you can safely start interior arrangement, installation of doors, windows. The construction of the house also includes the installation of communications - heating, ventilation, electrical wiring.

- Get to know the area. It is important to study the depth of groundwater, the level of swampiness. After all, it will depend on these factors whether your house will “play” or whether the foundation will undergo deformation.

- Documentation. Construction can only begin with a complete set of all permits, project and plan.

- Foundation waterproofing. It is better to do it twice - between the foundation and the plinth and between the plinth and future walls. Do not save, thereby ensuring the durability of the building.

- It is better to mark the foundation using a rope or a dense thread - this is a guarantee of accuracy.

- Provide the protruding part of the foundation with supports when pouring, otherwise its base will be less than the spread top, which can completely break the boards with its weight.

- The most suitable type of foundation for our climate and relief is strip foundation. If the house is planned on several floors and a large area, you need to make a deep foundation. Keep in mind that you need to think over the course of communications so as not to destroy it later.

- Quality. The better the material, the longer the building will last. Choose even bricks without cracks and chips, with clear corner lines and even color. Consider the strength, which is indicated on each brand of brick. M50, for example, can withstand 50 freeze and thaw seasons, respectively.

- For more warmth, use heat-insulating materials in the masonry. Although it is possible to make thermal insulation from the inside of the walls.

- Remove the excess solution immediately, otherwise it will harden and you will see a “grimy” and sloppy house. After hardening, it will be difficult to get rid of this daub.

- To keep the walls straight, brick to brick, stretch a rope or thread from one corner to another.

- After raising the walls, a break of about six months is necessary. During this time, the walls will settle and firmly set in place. To avoid excess moisture, cover the last row of bricks with roofing felt or film.

- If the site is not electrified, purchase a generator.

- The brick gable of the future roof is installed before the installation of the rafters. In order for it not to bend and be resistant to the wind, additional support is needed in the form of transverse masonry or pilasters.

- To keep the adjacent wall strong, make a bunch every 2-3 rows. To prevent the wall from moving, make a recess in the brick with a grinder under the height of the connecting element.