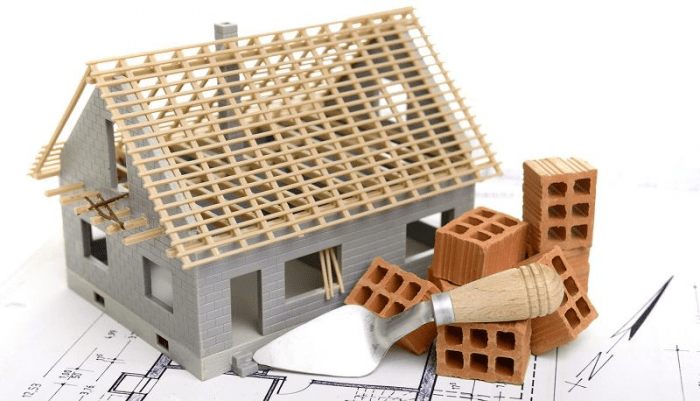

Is it possible to build a brick house yourself. How to build a brick house inexpensively, with your own hands. Roof installation in brick buildings

Building a house for a family causes positive emotions from the expectation of your corner, concerns about the correct laying of the foundation and the choice of material for the walls. A variant of the structure, which has a margin of safety in comparison with aerated concrete blocks, is a brick house. The materials, tools and step-by-step instructions required for construction will be described in the article.

Benefits of a brick house

Choosing a material for building a brick house is easier if you know about its pros and cons. With regard to the brick of the pluses, it is worth noting:

- strength;

- frost resistance;

- durability;

- fire safety;

- environmental friendliness;

- soundproofing properties;

- aesthetics;

- self-laying.

A brick wall can withstand three times more loads than a foam block wall. To increase strength, laying is carried out in several rows of bricks. Installing a roof on brick walls requires less preparation than for a house made of foam blocks. This fact is explained by the density of the brick, which prevents the block from cracking under the weight of the beams. Brick pores are smaller than those of gas blocks and foam blocks. Due to the structure, less moisture gets into the brick, which is the key to frost resistance. Moisture does not expand in frost, so cracks do not appear and the service life is tripled. The brick is made of natural materials. On the one hand, it is an indicator of environmental friendliness. On the other hand, the brick is resistant to high temperatures and fire, which speaks in favor of the fire safety of the building.

With proper laying, the brick performs soundproofing properties, cutting off extraneous sound coming from the street. Rest in a brick house is comfortable and calm. No other material can be compared with facing brick in terms of decorative properties. The surface, lined with bricks, retains its appearance for a long time without maintenance. The plaster that is laid on top of porous building blocks crumbles and needs to be repaired, which incurs unplanned expenses in the family budget. Laying bricks is easy with your own hands if you have experience in the construction industry. The skill is acquired when building walls with the help of an experienced craftsman.

Disadvantages of a brick house

An honest assessment of the properties of a material requires knowledge of its shortcomings. The disadvantages of brick are:

- the size;

- use of solutions;

- thermal conductivity;

- temperature inertia;

- the need for finishing;

- shrinkage;

- price.

The size of bricks for building walls is smaller than that of porous blocks. Masonry requires more time than when building walls from gas blocks and foam blocks. The solution is to build walls with warm ceramics having a block size of 51x25x29. Brick laying is impossible without wet mortars, which imposes restrictions on work in the cold season, when the moisture in the mortar freezes, stopping work. The set of strength of the cement-sand mortar takes longer than the adhesive for foam blocks and gas blocks. Brick is a cold and inert stone. It takes more time and more fuel to warm up a house made of bricks than, for example, for frame structures. At the same time, the brick quickly releases heat into the air, which requires constant temperature maintenance and warming of surfaces laid out of stone.

Loft style allows the use of a brick wall without finishing. For other styles, plastering and wall finishing are performed, which require additional costs from the budget. You can save on the basement or garage of a brick house, where the walls remain bare. After the erection of the walls of a brick house and before the start of finishing work, the period necessary for the shrinkage of the building is expected. Due to shrinkage, small cracks appear on the walls, which destroys the finish, so it will only be more expensive to rush. In cold regions, shrinkage of a brick house occurs within a year or more. The way out is drywall and materials that are resistant to deformation of the walls. The cost of high-quality bricks is higher than that of heat-insulating blocks.

Preparatory work

Preparation for the construction of a brick house begins with the selection of a site and a project for the needs of the family. The site is cleared of surface debris, after which a layer of turf is removed from the area where the building will stand. If the site is sloping, a suitable type of foundation is selected or the surface is leveled.

Brick house projects

The first step in choosing a project is to determine the number of storeys of a brick house. The expediency of the second floor depends on the number of residents and on the cost of heating the house. The project takes into account:

- attic;

- garage;

- number of bedrooms;

- kitchen;

- canteen;

- terrace;

- number of bathrooms;

- technical room;

- type of roofing system.

The attic of a brick house replaces the second floor. Therefore, it can be envisaged as an alternative to the second floor, which will save material and money for building a brick house. A truss system is selected under the attic. The space in the attic will increase the sloping roof. The available area in this case will be up to 95% of that on the main level. For the attic of a brick house, a method of natural lighting is selected, represented by dormer or end windows. At the same time, the first windows are much more expensive than the second ones, but the correct design of the truss system is necessary for the end windows. A garage is included in the project of a brick house. The building can be located under the house or adjacent to it. If it is impossible to build a garage adjacent to the house on the site, then a separate building is being built.

The number of bedrooms, bathrooms and toilets in a brick house is calculated from the needs of the family, as well as the guests visiting the house. A kitchen combined with a dining room takes up less space than two separate rooms. Serving food in a combined kitchen is easier than in a separate one. The project includes a terrace or veranda, if necessary. The technical room in a brick house is used to accommodate a washing machine, dryer and heating appliances. The project includes the amount of bricks and finishing materials required for the construction of the building. In accordance with the estimated weight of the brick house and the type of soil on the site, the type of foundation is selected.

Stages of building a brick house with your own hands

When the technical part of the brick house is agreed upon, the choice of the type of brick for construction and its purchase is carried out.

Brick selection

When choosing a brick, take into account:

- material;

- hollowness;

- the size;

- price;

- workmanship quality.

As a brick material is considered:

- ceramics;

- silicate;

- clinker;

- hyperpressed.

Sand-lime brick was popular in the construction of houses, as can be seen from the abundance of buildings from it. In addition to the form, he has no pluses. Brick has a high heat dissipation, which makes the building cold. Ceramic bricks have less heat transfer compared to silicate bricks. Another name is "red brick". Brick production is carried out by firing molded clay at a temperature of a thousand degrees. The brick owes its color to clay, but the shade is changed by adding pigments to the material. When choosing red brick for building a house, it is important to pay attention to the quality of firing. A brown-red color is considered normal, which turns green when struck. Insufficient firing is expressed in a mustard hue and a dull sound from impact. An overexposed brick is identified by the black edges and core. Red-brown brick is suitable for building walls.

Advice! A batch of bricks from the selected material must be inspected for damage and correct geometry.

Hyper-pressed brick is processed under high pressure. The composition of the stone includes mountain calcareous rocks, dolomite, shell rock and marble. Substances are crushed and placed in molds for pressing. Processing takes place not only with great weight, but also with high temperature. From under the press, the bricks come out dense, which explains the minimum moisture absorption. The amount of moisture affects frost resistance, reaching 150 cycles. A hyperpressed brick house will last 150 years with proper maintenance. The disadvantage of bricks is high thermal conductivity in comparison with red bricks, heavy weight and high price. Putting it is easier than red, because the geometry of the block is correct, and the lines are even.

Note! Clinker bricks are used for wall cladding due to their high cost.

How many bricks do you need for a house

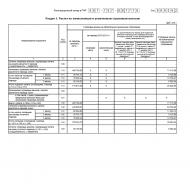

The calculation of the number of required bricks is carried out in accordance with the project, taking into account:

- wall thickness;

- masonry type;

- brick size;

- wall height;

- seam thickness.

According to the plan, the perimeter of the brick house is determined. To do this, you need to sum up the length of each wall. Knowing the perimeter, the area is determined. The resulting sum of the length of the walls is multiplied by their height. If the length of each wall is 7 meters, then the perimeter is 28 meters. With a height of 3 meters, the area of \u200b\u200bplanes will be 84 square meters. The laying of the wall is not continuous. There are window and door openings, it is required to determine their area and subtract it from 84 square meters.

Advice! When laying gables with bricks, their area is also taken into account.

To obtain an accurate result, the height of the masonry joint is subtracted from the height of the wall. When laying a wall three meters high, about 45 rows will be obtained from a standard brick. The height of a standard block is 6.5 cm. With a joint thickness of 0.5 cm, the height of all joints will be 28 cm, which is equivalent to four rows of bricks. It turns out that for laying a wall of three meters, 40 rows are needed. For laying a square meter of a wall of standard brick, taking into account the thickness of the seam, 61 elements are required. To determine the number of bricks for four walls, 84 is multiplied by 61, which is 5124 elements. When laying in two bricks, you will need twice as much material or 10300 elements, this is without taking into account the gables.

Advice! The area is calculated only for the outer walls. The number of bricks for interior walls is determined by the given sample.

Basic construction work

The main construction begins with laying the foundation. The foundation of a house made of bricks requires precise calculations, since the weight of the building is two or three times that of a similarly sized lightweight block structure.

Pouring the foundation of the house

On the site with the removed turf, marks of the corners of the house are installed. The correctness of the beacons is checked by the length of the diagonals, they must match. The second beacon is dug in next to the width of the wall. A fishing line or twine is stretched between the lighthouses. Thanks to the fishing line, it is easier to dig a trench. The illustration above shows how you can still check the correctness of right angles. The depth of the trench is selected in accordance with soil studies, the main of which is the freezing point. When digging a trench, it must be passed so that the expanding moisture in the soil does not force it out. The bottom is compacted in the finished trench. This is done manually or mechanically. A pillow of sand and gravel is laid at the bottom. Each layer is made 20 cm thick, the layers are leveled and rammed. Next, the formwork is mounted to the height of the foundation above the ground level. A metal frame is laid inside the formwork and supporting elements are installed to keep the walls from concrete pressure.

Foundation waterproofing

The first stage of waterproofing is carried out before concrete is poured. Roofing material is laid on top of the pillow in the trench. The sheets are overlapped to prevent the concrete from being pushed through. It is more efficient to fill the entire area at once, to obtain a monolithic foundation. The foundation concrete under the house is compacted with a deep vibrator to fill all the voids. The surface of the foundation is leveled with a rule and a trowel. The formwork from the foundation for the house is removed after a week or two, depending on weather conditions. Next is the external waterproofing. The walls of the foundation under the house are covered with roofing material or bituminous mastic. If insulation is planned, then the foam is placed under the roofing material, but on top of the bituminous mastic. Waterproofing is also carried out for the upper part of the foundation before laying the walls to prevent capillary movement of moisture along the walls of the house.

Advice! Before pouring, communication shafts and sleeves are laid under the foundation.

Brickwork walls

Laying the walls of a brick house is a responsible process. The first block is laid from the corner of one of the four walls. For ease of leveling the brick in a horizontal plane, a fishing line is stretched under the house along the edge of the foundation. The fishing line is placed at a height that is equal to the height of the brick plus the seam. The corner block of the wall is exposed in three planes. After laying the first row of wall bricks, the fishing line moves to the next. Checking the horizontal level with a bubble device is carried out every two rows. The deviation from the vertical at the height of the wall should not exceed 1.2 cm. Each next row of bricks of the wall is laid with the intersection of the seams to ensure the strength of the plane of the wall of the house.

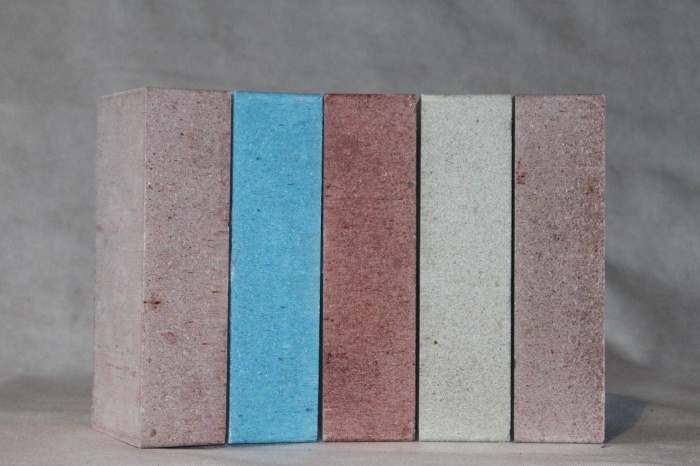

The mortar is applied to the stacked block or the mounted row of the wall. The composition is evenly distributed over the surface. The chipped part of the block turns inward to keep the face of the block attractive. When laying a wall in two bricks with a space between the walls, a binder block is made. You can combine partitions with the main walls with blocks laid across. Types of block masonry are shown in the photo above.

Window and door openings in brick walls

When the walls are pasted out, space is left for window and door openings. Their laying is carried out simultaneously with the construction of walls from blocks. A metal or concrete lintel is mounted above the opening in the wall, holding the subsequent rows of masonry. The jumper can be cast in place. To do this, when the required level of the wall is reached, formwork is set, metal reinforcement is laid and concrete is poured. The laying of blocks on the wall is continued after the strength of the lintel has been cured.

Ceilings in a brick house

In a block house there are such types of floors:

- basement;

- basement;

- interfloor;

- attic.

Overlappings are used to separate the premises of a brick house. Ceilings are made of wooden beams, which are sheathed with finishing flooring or from concrete slabs. Plates are laid ready or poured in place. Metal beams are used for laying floors in a block house. The advantage of metal and concrete floors in a brick house is their strength. But floors of this type have a high thermal conductivity in comparison with wood, therefore, they require high-quality insulation. Lifting equipment is required for laying concrete slabs, and a reinforced belt is also constructed to distribute the load. The maximum length of the span covered by the reinforced concrete slab reaches 12 meters.

Wooden floors in a brick house are limited in length to six meters. When covering large areas, supporting elements are mounted in the form of internal walls or pillars. A metal channel covers distances of more than six meters without the use of supports in a brick house. In this case, the size of the channel increases in proportion to its length. Wooden and metal floors require maintenance in the form of repainting and treatment with antiseptic compounds against corrosion. Regardless of the material used to make beams for floors in a brick house, they must:

- withstand the load;

- be rigid;

- have soundproofing;

- have thermal insulation if the temperature difference in the rooms is more than ten degrees;

- be resistant to fire.

The distance when laying metal beams is up to 60 cm, for wooden beams the distance varies depending on the thickness of the board.

Roof of a brick house

Any configuration for a roof in a brick house is allowed:

- gable;

- lean-to;

- flat;

- broken line;

- hip.

There are no restrictions on the form for brick houses, because brick walls withstand wind and sediment loads from rain and snow. The construction of the roof of a brick house is shown in the video.

Construction of interior walls

The internal walls of a brick house are built from bricks used for external walls, or from lightweight blocks: gas blocks and foam blocks. The laying of lightweight blocks is faster, they are lighter and provide better sound insulation compared to bricks. When building walls from lightweight blocks in a brick house, a metal mesh is laid in two rows to stiffen the wall plane. Interlacing of internal walls from blocks with external from a brick is made. Internal walls are built together with external ones if they act as a support for the truss system. If the partitions are not supports, then they are erected after the installation of the ceilings and the truss system. The construction of the internal walls of a brick house is described in the video below.

Installation of windows and doors

The installation of windows and doors in a brick house is carried out after a rough interior finish, which includes plastering and grouting the walls. Window and door frames are mounted in wall openings on wedges. Wedges allow you to set the position of a window or door in three planes. After aligning the windows and doors in a brick house, the structures are attached to the walls with frame anchors. The space between the window frame and the door is filled with foam. Excess foam is removed after polymerization.

Laying communications

Installation of communications in a brick house begins with their supply to the house. Pipes are laid through sleeves laid before pouring the foundation of a brick house. The exception is the gas main, which is introduced according to the project through the wall of a brick house. The layout of the water supply in a brick house begins with a bathroom and a bathroom. Further pipes are led to the kitchen. The drain pipe is laid with a slope of 2 cm per meter to drain the liquid into the sewer. For safety, an anti-leakage system is installed that automatically blocks the flow of water in the event of a breakthrough. Hot and cold water pipes are covered with thermal insulation to maintain temperature and prevent water condensation. A video about laying sewers in a brick house is below.

Floor device in a brick house

The device of the floor in a brick house is determined by the type of floor. If wooden beams are laid in a brick house, then an edged board is knocked out from below the beams, on which waterproofing is laid and a heater in the form of mineral wool is placed in the cavities between the beams. From above, the cotton wool is covered with a layer of waterproofing and a draft floor is mounted from the edged board. The finishing flooring or mats under the warm floor are laid on the edged board, after which the cladding is performed. For floors made of metal beams, the floor is equipped in the same way as for wooden ones. A rough screed is poured onto concrete floors and insulation is laid. Next, the installation of a warm floor or finishing flooring is carried out. Floor insulation in a brick house is shown in the video.

Insulation of a brick house

Warming of a brick house is carried out with foam plastic, extruded polystyrene foam or mineral wool. If the finishing of a brick house is planned with decorative plaster, then the installation of the crate is not performed. The insulation is attached to the brick wall with plastic umbrellas that are inserted into the drilled holes. Five umbrellas are consumed per sheet of insulation. On the reverse side, the insulation is covered with glue for adhesion to the brick wall. The seams between the insulation are filled with glue. A fiberglass mesh is applied to the insulated brick walls, which is fixed with glue.

Facade decoration of a brick house

On the glue applied to the grid, finishing with decorative plaster is carried out. The plaster is applied after three alignments with grout. When finishing with siding or facade panels of a brick house, a crate made of wood or a metal profile is mounted after insulation. A facing material is attached to the crate. Before facing the mineral wool, waterproofing is laid, blocking the penetration of moisture to the insulation and the brick wall.

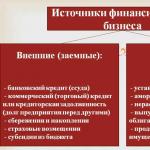

What determines the cost of a brick house

The cost of a brick house consists of the materials spent for its construction. A large area of \u200b\u200bthe house requires a lot of money. The amount is affected by the type of brick used in the construction of walls, the thickness and height of the brick walls. Brick consumption affects the amount of mortar for masonry. A tall building needs a solid foundation, the width and height of which are proportional to the consumption of concrete. Increases the estimate of payment to workers, the supply and connection of communications, the delivery of goods to the construction site.

Despite the variety of building materials (and today foam blocks, cinder blocks, aerated concrete, frame houses, etc. are available on the market), brick remains the most common solution for construction. It is durable and relatively cheap, has excellent thermal insulation properties and looks great with any design ideas. In addition, it is universal and can be used to make both a one-story and multi-story house, attach a veranda, porch or other structures.

However, in order for your home to be reliable and durable, you need to build it correctly. First of all, a project is being developed, which indicates the scheme of the building, from which stone it will be erected, the calculation of the material and other nuances. You can see the drawings on our website. Today we’ll talk about how to build a brick house with your own hands, and what features you need to consider.

Foundation

Every design needs a good foundation. For a brick house, deep strip foundations are used, since they are able to withstand the load of a heavy structure, and they are relatively inexpensive. Structures of this kind fall into three categories.  in particular:

in particular:

- Monolith. It is used in places where there is a risk of uneven shrinkage of the building. It is one-piece and acts as a single structure, which avoids deformation of the walls.

- Made. Not as strong as monolithic, but cheaper and much easier to equip.

- Mixed. A hybrid between the two above.

Walls

To build walls, you will need a special mortar. It is divided into three types:

- Three-component. Classic, consisting of sand, water and cement.

- Lime. The same, but plus lime.

- Plasticizer. It is made more difficult, but it is considered more reliable for bricks.

Before starting work, experts advise laying out the bricks in a pile around the perimeter of the future construction, so as not to constantly run after the stone to one specific place. For a couple  hours before starting work, the stone should be thoroughly moistened. In addition, decide on the corner points and directions of the walls, which will help you with a tape measure and thread.

hours before starting work, the stone should be thoroughly moistened. In addition, decide on the corner points and directions of the walls, which will help you with a tape measure and thread.

Laying always starts from the corner, gradually moving along the length of the future wall. You can make two rows of stone, laying a heat-insulating layer between them. In order for the mortar to be evenly distributed, it is necessary to lay a new stone on the mortar and smoothly adjust it to the one standing next to it. To make the material fit better, it should be tapped with a trowel handle. Consider some rules that you definitely need to know when working on your own:

- red brick is laid in the lower rows, not silicate. It is also used for rooms with high humidity and chimneys;

- you will need to reinforce the walls to increase their strength;

- during laying, it is not necessary to clog the seams with cement mortar completely, because this will complicate the finishing;

- you need to carefully monitor the level of masonry.

In addition, it is necessary to ensure that the insulation certainly remains dry. If you take a break from work, hide it or just cover it. Just a few simple and clear rules will help you make the masonry fast, but of high quality.

Overlappings

Overlapping is a layer that separates one floor from another, as well as the main residential part from  attic. They also have a number of requirements that you need to be aware of:

attic. They also have a number of requirements that you need to be aware of:

- must be strong and withstand any load;

- be rigid, do not bend over time;

- are required to meet the requirements of thermal protection, since in the cold season the temperature in the room and outside the floors is very different.

If you are building a one-story house, you need to ensure that the floor meets the requirements for thermal protection. This is a top priority. With multi-storey buildings it is more difficult, the load requirements are higher there.

Roof

The roof should reliably protect your house from bad weather. It is subject to increased requirements for strength, it must withstand not only the force of a hurricane wind, but the mass of snowdrifts. If you are building a one-story house, a pitched roof with one or another slope will suit you. For residential premises, gable or four-pitched roofs are used; for outbuildings, a single-pitched roof is enough.

Building your own home is a very real task. However, you need to prepare for a huge investment of time and money. However, if you are ready to start your construction, the photos and videos posted on our website will help you achieve an excellent result. Follow all the steps according to the instructions, and your home will never let you down.

Turnkey construction of brick houses in Moscow and the Moscow region from 18,000 rubles per meter. This price includes a gas silicate block + facing brick, foundation, walls, roof, screed. When building a brick house with our company, the design of the house is free of charge. Aerated concrete lined with bricks allows you to reduce the load on the foundation, reduce heat loss and reduce the cost. The state employs 50 highly qualified teams that regularly take special courses to improve their skills.

Benefits of building a brick house

- Durability and strength of the structure

- Great looking home

- High degree of fire protection

- Wide architectural possibilities

- Immunity to decay and microorganisms

Disadvantages of building a brick house

- The price is higher compared to gas-block houses

- Sufficient weight of the material, the rise in the cost of the foundation

- High thermal conductivity - the need for thick walls

- Tendency to saturate with moisture (hygroscopicity), the need to constantly heat the house

When building a brick house in the Moscow region and Moscow, the specialists of the SVS company are guided by building codes and standards. It all starts with calculating the depth of the foundation. The depth is affected by the heaving and quality of the soil, the magnitude of the expected load. A pillow of sand and gravel is necessarily laid under the metal-concrete base, and the foundation itself is covered with waterproofing material. Having decided to entrust the construction of a turnkey brick house to the SVS company, our employees will calculate the number of bricks per house so that there are no surpluses that are simply thrown away and you do not have to overpay. When laying, SVS specialists lay every third layer of bricks and blocks with a reinforcing mesh, which gives strength to the structure.

The cost of building houses with brick cladding - from 18,000 rubles m²

Brick house - the price of construction in the suburbs and Moscow

The price of building a brick house per m2 in SVS starts from 18 thousand rubles. This is a building made of gas silicate block, lined with brick. This includes pouring the foundation, screeds, erecting walls and roofs. The cost of building a brick house, where a ceramic block is laid at the base, is slightly higher and amounts to 19 thousand rubles.

The cost of individual design - 250 rubles per 1 sq. meter.

When building a house with our company - design is free of charge

Deciding to entrust the construction of a turnkey brick house in Moscow and the region to us, you will receive one hundred percent compliance with all building codes and state standards, exact deadlines, unsurpassed quality, the conclusion of a formal contract, price stability during the work process, total control over the construction site - photo and video reports every week and the ability to set online surveillance. Before ordering the construction of a brick house, you can see the projects and prices directly on the SVS website or check with the manager. The company's specialists have developed hundreds of ready-made projects of brick houses with an already calculated estimated cost.

Many experts call a brick house the standard of durability and strength. Subject to the recommended technology, such a dwelling can be built with your own hands, and then enjoy a comfortable life in it for decades.

A huge number of people are attracted by the prospect of living in a private house. Especially if its construction is carried out from scratch and independently. Indeed, in this case, a person gets a unique chance to create the house of his dreams. An ideal home can be built from various building materials. One of the most popular in this case is brick. Residential buildings from it have the following advantages:

- relative availability of building materials;

- good level of thermal insulation;

- durability and reliability;

- the possibility of implementing original projects using different types of front and ordinary bricks;

- high strength;

- the ideal microclimate in the house due to the fact that the described material has a special structure that allows the dwelling to breathe;

- the possibility of erecting a private building with several floors.

Private brick house

In addition, brick can be used in combination with many other building products and materials. Thanks to this, any fantasies of a private developer can be translated into reality. The main disadvantage of the buildings under consideration is usually attributed to the severity of their construction. This problem is dealt with by building reliable foundations with special characteristics. The second minus of a brick house is the high cost of building materials. They can really be reduced by 15–25 percent if porous bricks are used.

Another disadvantage of such residential buildings is that bricklaying can be carried out exclusively in the warm and dry season. At this point, a person needs to correctly calculate the time when the construction of his dream house will be carried out.

In order to build a residential building, you need to find a good plot of land for it, draw up a construction project, prepare and approve the documents for the work, decide on the type of foundation and building materials that will be used. You can draw up a house project yourself or choose a ready-made solution. In the second case, the probability of incorrect design is reduced to zero. But you still have to research the site where the construction will be carried out, as well as perform a lot of additional calculations.

If the project is being prepared with your own hands, it is imperative to take into account the existing financial budget and focus solely on it. Also in this case, you need to decide what construction activities you can do yourself. To build a home without spending too much money, it is important to choose the right brick. It can be hollow and full-bodied, as well as facing and simple. Everything is simple here. Hollow products make it possible to reduce construction costs and the load on the foundation of the house. The load-bearing elements of the building are erected from solid bricks.

brick house project

Face products are good for building decoration. But all the partitions of the building and its box are best made from ordinary bricks. Then the construction will be cheaper. In addition, you should pay attention to the following characteristics of the material used:

- integrity and accuracy of geometry;

- water absorption coefficient;

- thermal conductivity;

- resistance to low temperatures;

- strength.

The next preparatory step is the calculation of the required number of bricks. It is necessary to determine the area of \u200b\u200bbearing walls (their height should be multiplied by the perimeter of the building) and subtract the area of \u200b\u200ball openings (windows, doors) from the resulting indicator. Then choose a specific option for laying bricks. For this, special tables are used. From them you will find out the required number of products for the construction of one square of the wall. This number must be multiplied by the quadrature (total) of the wall surfaces to obtain the total need for building materials.

It is also necessary to choose the type of mortar that will be used for masonry. It can be lime, cement or combined (cement-lime). The basis of such mixtures is well-sifted river sand. Its ratio to cement varies between 1:3–1:6. With your own hands, it is easiest to work with a combined masonry mortar. It has a fair amount of lime. It plays the role of an effective plasticizer. The cement mixture always turns out to be inelastic. Its difficult to use. Although such a solution provides maximum masonry strength.

The key to the successful construction of a brick house with your own hands is the competent selection of its foundation. Experts recommend opting for a strip foundation. Structurally, it repeats the lines of the building under construction (its load-bearing walls), which gives the structure the required strength. You can also equip a pile, slab or. In some cases, they are more suitable for construction than a strip base.

The choice of the optimal type of foundation depends on the mechanical and physical properties of the soil on your land, the depth of soil water, the terrain and other factors. The construction of any of these foundations for a house consists of several general stages:

- digging a pit;

- creation of a special pillow (sand plus crushed stone);

- installation ;

- knitting reinforcing elements;

- pouring concrete mortar;

- foundation waterproofing.

Arrangement of the foundation of a private dwelling

Concrete at the base of a brick house must be fed in horizontal stripes. Then the mixture will not crack.

Remember that concrete mortar hardens in 6-8 days. But laying bricks on the erected foundation is allowed only after a month. Do-it-yourself waterproofing of the base of a residential building without problems. You need to lay out 2-3 layers of roofing material or hydroisol on the foundation surface and fix the insulating materials in a convenient way (glue, use fasteners). Without carrying out waterproof measures, the construction of a house is not carried out. Melt water and groundwater will very quickly destroy the foundation, and then they will take over the rest of the structure of the residential building.

Do-it-yourself brickwork, as a rule, is carried out according to three common schemes: well, in 4 bricks, lightweight. Well technology involves leaving special voids inside the masonry. Subsequently, they are filled with foam or expanded clay. Due to this, ordinary brick provides a higher thermal protection of the house. Masonry in 4 bricks is carried out using a special metal mesh. It is needed for additional strapping of rows of building products. The mesh increases the rigidity of the masonry. It is mounted every 6-7 rows.

A lightweight technique is that bricks are first placed at the corners of the walls (bearing). The number of products for each corner is from 5 to 10. A charming condition for the process is the use of a plumb line when performing masonry. Bricks must be strictly vertical! The durability of the house under construction and its attractive appearance depend on this.

Brick masonry using a lightweight technique

Do-it-yourself wall construction is carried out according to the following algorithm:

- Knead a small portion of the solution, achieving its maximum elasticity.

- Apply the mixture to the desired area, very carefully (and at the same time quickly) align it. Some of the solution must be brought to the brick located in the row. Remove any excess mixture immediately with a trowel.

- Lay a brick on the mortar and tap it with the trowel's handle. This will ensure a high-quality fit of building products. It is advisable to maintain a distance of about 1.2 cm between individual brick rows.

- Lay the last item in the row. In most cases, when doing work with your own hands, putting a whole brick on the edge does not work. You will either have to chip off a piece of material of the required size, or adjust the gap between adjacent products by filling them with a cement mixture.

- Stitch all masonry seams. If you will finish the walls with facing bricks, the jointing should be done so that there is no free space between the rows of building material. But in cases where the surfaces will be plastered, small voids should be left in the seams. Then the plaster will lie more qualitatively on the walls to be lined.

Do not forget to leave empty spaces on those sections of the walls where doors and window openings will subsequently be mounted.

The roof frame of a brick house is recommended to be constructed from pine or hardwood timber. It needs to be treated with refractory and antifungal compounds. And then perform the following actions: mount a Mauerlat from 150x150 mm beams on the walls, put a frame. You will need to attach wooden rafters to the Mauerlat. Fix them with nails, crate OSB boards or plywood sheets. The crate for the installation of bituminous tiles is made solid, for metal tiles - in increments of about 35 cm, for slate coating - about 80 cm.

Roof frame of a brick house

Next, protect the roof from moisture. Here it is desirable to use modern types. Mount the selected roofing products and (if provided by the project) decorative elements. If necessary, make a vapor barrier and insulation of the roof. Now your brick building is protected from the weather. You can equip it at any time of the year - lay water, gas and other communications, install doors and windows, make floors.

As you know, every man must do three things in his life. One of them is to build a house. This is a very responsible stage that requires certain knowledge and skills. To realize your dream, you need to consider where to start work, what you need to buy and what stages of construction you need to overcome. Despite the fact that today there are new technologies and building materials, brick is often chosen as the material for the house. And this is not surprising, since it has a number of advantages, such as environmental friendliness, acceptable thermal insulation properties, fire resistance, durability, reliability and excellent appearance.

In this article we will tell you how to build a brick house with your own hands, we will demonstrate drawings, photo and video instructions. Even if you don't have bricklaying experience, you can do the job.

What you need to know before building

Design

Design

Before you start building a house, you need to do some preparatory work. It is noteworthy that you will not be able to simply buy a plot and start building a house there. More precisely, you can do so, but such construction will be illegal.

First you need to obtain a building permit from the district administration. To do this, you need to collect the necessary package of documents: a statement of construction, copies of property rights, purchase and sale, passports and other documents. Among them, there should be drawings of the future construction, and coordination with various services. Once your application has been reviewed, you will be issued a building permit. This can be done after the completion of construction work through the court, but still, in order to avoid problems, it is better to take care of this in advance.

The preparation also includes the choice of location, planning, and the purchase of materials. It is also important to determine the type of foundation, the choice of bricks, the laying method and the roofing material. If everything is prepared and thought out in advance, then all the work will be easier and faster.

It is important to decide which of the works you can do yourself, and which should be entrusted to specialists.

After everything is done, you can start building. All work can be divided into the following stages:

So, let's take a closer look at how to build your own brick house.

Procurement of tools and materials

Tool

Tool

Building a house is not an easy task, but it does require some effort, skill and planning. But, even having all this, it is impossible to imagine a construction site without the necessary tools and materials. Therefore, for such work, you will need the following tools:

- building level;

- level;

- construction hammer;

- trowel, trowel;

- Bulgarian;

- stitching;

- plumb;

- building cord;

- shovel;

- concrete mixer.

Sand for masonry mortar

Sand for masonry mortar

If we talk about materials, then you need to purchase the following:

- brick;

- cement;

- lime;

- sand;

- plasticizer or liquid soap;

- fittings;

- plywood or boards;

- insulation (slag, mineral wool, foam plastic, expanded clay);

- hydroisol or roofing material.

All this can be purchased at any hardware store.

Which brick to choose

Brick

Brick

Since you can find different types of bricks in building stores, you should decide which brick to build a house from. The most popular and leading options are red clay and silicate bricks. When laying, they can be used individually, as well as combined with each other. As experts advise, when laying in the middle, you can add insulation. Since such bricks are quite heavy, the load on the foundation will be appropriate. To reduce it, you can use a brick with cells. This is a lightweight version of a regular brick that weighs 20% less than usual.

To make the masonry even, beautiful and reliable, do not buy a brick that has already been used. Your material must be whole, of the correct form and without cracks.

After all the necessary tools and materials have been prepared, you can proceed to the next stage - planning.

The second stage - planning a house

Home planning

Home planning

As you know, you can not build something without first planning everything. Therefore, to begin with, it is important to decide what the building will be used for. If it is a small country house, in which you plan to live during the warm period, then you can build it in half a brick. If the residence is intermittent, but at any time of the year, then the walls can be laid in one brick. In this case, the building will even withstand several floors. Well, when you plan to build a house for permanent residence in it, the thickness of the walls of such a house is recommended in one and a half bricks.

Drywall partitions

Drywall partitions

If you decide to build a one-story house, then the foundation can be simplified. In this case, the walls of the house will be made of drywall. They don't need to be reinforced. But when the partitions are built of brick, the foundation will look different. Since the future building will be made of brick, which has a high density and, accordingly, gives a large load on the foundation, the foundation for your house must be strong enough. The most reliable is the strip foundation, the design of which exactly repeats all the lines of the walls and partitions of the building. Then you need to fill the foundation under each wall and partition. In this case, the entire load from the walls is distributed over the entire area of \u200b\u200bthe soil, and therefore the stability of the building increases.

Marking the future site

In order for your building to have the correct location, and during the construction process you can avoid unnecessary problems, you need to make markings on the ground that correspond to the plan of your house. Hammer the stakes into the ground where the corners of your building will be, as well as where the piers will be erected. It must be the actual size. Then take a rope or a thick rope and pull it over all the pegs. Thus, you have made a kind of landmark that will help you dig a trench for the future foundation. You can check the horizontalness of the stretched rope with the usual level.

After everything is done, it remains to take shovels and dig a trench according to your guidelines. To do this, you can ask the help of your friends, relatives or neighbors, since it will be very difficult to do everything yourself. Especially when the house has several floors, the depth of the trench can be up to 2 m.

Foundation formwork

Foundation trench formwork

Foundation trench formwork

Based on the technology, the foundation must be arranged 10–15 cm above ground level - this is the minimum indicator. In regions with severe winters, the plinth can be even 40-50 cm. To do this, you need to install formwork along the edge of the trench. It can be made of plywood or ordinary boards.

In the event that the surface of the site is uneven, you need to find the highest point and start from it.

In order for the foundation to be made in one plane, the formwork must be brought in height to a stretched rope and supports should be made. It is important to remember that the higher the formwork, the more often and closer you need to install props. If this is not done, the mass of concrete can crush the entire structure, and it will spread or be uneven.

In order for the formwork to securely hold the concrete, it must be made strong: without holes, gaps, since the concrete can flow through them. Often planed board or plywood is used for formwork, but you can choose other material at hand.

Cushion under the strip foundation

Cushion under the strip foundation

Before you start pouring the foundation, it is important to make a pillow at the bottom of the trench, filling it with small gravel, stones or sand to a depth of no more than 5 cm, after which it must be tamped. If you do not have a vibrating plate or rammer, you can use a homemade fixture. To do this, take a wooden beam with a section of 150 × 150 mm with a height convenient for you and attach handles on the sides. Using brute force, compact the entire trench. Thanks to such a pillow, the shrinkage of the building will be much less, and the building itself will be more stable.

After that, the reinforcing cage is laid along the entire length of the foundation. To assemble it yourself, you will need:

- fittings Ø10–17 mm;

- fittings Ø5–8 mm;

- thin wire for knitting;

- Bulgarian;

- wire cutters;

- pliers.

Calculate how much reinforcement you need, you need in advance. It is important to consider soil data and the number of floors of your future home. We can say for sure that if you build a three-story house on loose soil, then everything will be to the maximum - both the depth of the foundation and the diameter of the reinforcement. To make an accurate calculation, you need a whole topic that takes into account all the subtleties and nuances, so it's better to use a calculator.

Foundation pouring

It is important to know that the foundation can be monolithic and prefabricated. The monolithic foundation is made immediately on the spot. To do this, a concrete solution is mixed, which is poured into the prepared trench. The prefabricated foundation consists of ready-made slabs that are laid in the ground. For a brick house, a monolithic foundation is much better suited, which is able to withstand huge loads. Even if you build several floors of the house, a basement and a garage, the structure will hold securely. The only drawback of a monolithic strip foundation is that it is not recommended to use it in soft ground. The best option would be a pile foundation.

So, it's time to pour the foundation of your house. To ensure the strength of the base of the house, the pouring must be carried out in horizontal stripes in one step. If you fill it partially or make separate vertical sections, then there is a high probability that these junctions may crack. Therefore, everything must be done quickly and not without additional help. Ask a friend or relative to help you, as extra hands are simply necessary in this matter.

Mixing concrete

Mixing concrete

The first step is to mix the concrete. This is a labor-intensive process in which concrete must be made, transported or transferred to the place where the pouring takes place. To fill the foundation, you will need a lot of concrete. If the depth of your trench is more than 60 cm, then after you have poured the first layer of concrete, throw rubble stones there and continue the process.

After you finish pouring the formwork, you need to compact the concrete by expelling air from it. A deep vibrator is well suited for this purpose. But since not everyone may have it, it is possible, using a thick stick, to compact the concrete with up and down movements. After such manipulations, the concrete surface must be leveled with a trowel. Basically, concrete dries for 5-7 days. But it is necessary to start laying bricks only after a month, when the concrete will gain strength and will not be pliable.

Waterproofing works

Foundation waterproofing

Foundation waterproofing

An important step before laying the walls is the waterproofing of the foundation, thanks to which moisture from it will not penetrate into the house or basement, and the brick will not collapse. Thus, you will extend the operational life of the foundation of the house and protect yourself from the formation of fungi and dampness.

Such work can be performed after the foundation has solidified. Everything is done quite easily, the main thing is the presence of a waterproofing material (hydroisol or roofing material). It must be laid or glued to the foundation in 2-3 layers. After the construction is completed, all excess pieces that will protrude should be cut off. The basement of the building should be coated with molten bitumen.

The basis for masonry - mortar

Solution

Solution

After a month, you can begin work on the construction of a brick box of the building. First you need to make a solution, thanks to which the whole structure will hold securely. The main type of mortar is cement-limestone, limestone or cement. The basis or base for any of them is sifted sand (it is better if it is river sand). To find out how to make a solution and in what ratio to take the components, just look at the packaging, where everything is indicated. The most common proportions of sand with cement or lime are 3:1 or 4:1. In this case, the future masonry will be very strong, and it will not be difficult to do it, since the solution will be inelastic.

To find the most qualitative ratio of materials in the composition, you need to check them in action, because sometimes low-quality cement comes across. You need to make several compositions with different proportions, for example, 3:1, 4:1 and 5:1. You don’t need a lot of composition - you only need it to make small balls out of them. Wait until they are all dry, and then hit them with a hammer. Pay attention to the ball that split upon impact, and did not crumble - such a ratio of components, as for the manufacture of this ball, must be chosen.

Building brick walls

Highlights of masonry brick walls

Highlights of masonry brick walls

After the solution is ready, you can start laying bricks. You need to start it with the removal of corners. The first bricks must be laid especially carefully and carefully, since further masonry and the general appearance of the future building depend on them.

At first it may seem that such work is simple, brick by brick and you're done. But it is very difficult for inexperienced masons to make the walls perfectly even and geometrically correct. To do everything right, you need to try and be patient. Such work is long and tedious, but you will gain practice that will help you further. What do you need to do?

To ensure quality masonry, you need to check the position of each brick.

You need to check the position of each brick

You need to check the position of each brick

On this, the frame of your future home is ready. It remains only to make the roof. It is difficult to carry out all the work on your own. Therefore, ask for the help of professionals who will provide you with a reliable roof over your head.

Now you can be proud of yourself, because you were able to realize the dream of every person on your own. As you can see, building a house on your own is difficult, but possible. Therefore, if you are planning to make a cozy home for yourself and your family, purchase material and get to work!