How to crochet armature. Rules for reliable reinforcement of strip foundations. Hook for knitting fittings

Knitting reinforcement is one of the main stages of work on creating a reinforcing cage. By connecting the reinforcement, a reinforcing structure is created, thanks to which the concrete receives greater strength both in compression and in tension. If the rods are connected incorrectly, the finished monolithic structure will not receive design strength. In order to avoid this, we will analyze how to properly knit reinforcement, observing all the rules and regulations, and with what tool you can do the job, this will be useful for beginners and experienced builders.

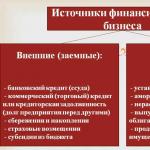

Let's consider all the existing methods of how to connect the reinforcement. Each of the options is good in its own way, and is used by builders, depending on the type of structure and design requirements. There are 3 ways to connect the rods, with their help a strong and reliable metal frame is created:

- Wire knitting.

- Welding.

- Plastic clamps.

These methods of knitting reinforcement have their own characteristics. Each of them is correct and is applied depending on the requirements and the material used. When reinforcing a strip foundation for a private house, they often connect the reinforcement by welding, and do not tie it with wire. But which option is the best?

Advantages and disadvantages of welding joints

Despite the fact that these are different technologies, the right choice can save money and time on construction, while without compromising structural strength. The method of connecting elements by welding was previously considered one of the most reliable and effective. However, this technology is not always appropriate. Usually it was used when installing bulky frames that reinforce the foundation for multi-storey buildings and overall cottages.

This method has some disadvantages:

- You need to have the skills to work with a welding machine, otherwise you need to spend money on the services of a professional welder. In this case, the cost increases.

- Welding points are the weak point of the structure. There, the strength of the frame becomes lower.

- The method is not suitable if you use . In addition, which is the most sought after, cannot be connected by welding. Only rods with index "C" are suitable for work, for example: rebar.

Therefore, in modern monolithic construction, welding was replaced by viscous. For private and residential buildings, the construction of a bathhouse, a garage or other buildings, this is the best option for connecting fittings.

Pros and cons of knitting

Why is this method so good? It has the following positives:

- The speed of work. Wire knitting takes little time, it is simple and does not require skills. True, if you do it manually, the process slows down. Next, we will look at how to quickly knit reinforcement.

- Ease of troubleshooting. When working with welding, it will be more difficult to eliminate errors, you have to take a grinder and cut the weld. It is enough to bite off the wire with wire cutters or unwind it with a hook.

- You don't need to be a professional to knit rebar.

- The reinforcement process can be performed in the formwork.

- The labor cost is much lower.

An example of knitting a mesh from reinforcement with wire.

If we talk about the shortcomings, then we note the precariousness of the finished frame. True, this is not a big problem. The structure will be strong, the only problem is that when the frame is moved into the formwork, it begins to loosen, in which case it is possible to make reinforcement tacks by welding in several places. To solve this problem with fiberglass reinforcement, it is necessary to tie several braces so that the structure becomes more rigid and stable. Bending, the stretch in the places of knitting changes, the frame walks. Therefore, when installing it in the formwork, you need to be careful. It is better to knit reinforcement in the formwork or above it, if performed.

Features of connecting fittings with plastic clamps

The main advantages of this method are that it does not require special skills, it has a high speed of work, and reliable fixation of the reinforcement.

The disadvantages of this method are the following:

- Price. With large volumes, the wire will be more economical.

- The speed of work (when compared with other knitting methods).

- Correction. Somewhere they made a mistake, you have to bite off the clamp, it becomes unusable, but the wire can be tied up.

- Reliability. Movement on a structure connected with plastic clamps is not desirable.

- Temperature. They burst at low temperatures.

Based on these data, we can say that this method is more suitable for private construction, with small volumes, it is also suitable for people who themselves want to do the reinforcement with their own hands.

Tools for knitting reinforcement, technology for working with them

Nobody does the work by hand. It's practically impossible. For this purpose, there are special tools that speed up and simplify the process. Each tool has its own characteristics for use. For a bunch of reinforcement, there are the following devices:

- Hand hook.

- Knitting gun.

- Screwdriver.

- Ticks.

Each of the tools has its pros and cons, we will consider them, as well as the technology for their use, and based on these data and the opinion of an expert (a rebar fitter with 10 years of experience), we will summarize and choose the best option for knitting reinforcement.

How to crochet armature?

The peculiarity of the work is that it is done manually. At first, the process will be lengthy, as you need to fill your hand. The hook is made of steel, and the handle is made of wood or plastic. The cost of such a hook is 1 thousand rubles.

There are even automatic hooks on sale, but reviews about them are twofold. Some note a small resource, others say that it is difficult to twist wire with a thickness of 2 mm or more.

There are several options for connecting knots when crocheting reinforcement. Consider the most popular.

A simple crochet armature knot

The most common and simple knot is performed as follows:

- To connect the rods to each other, you need to take a wire 15–20 cm long and bend it in half.

- The bent wire bends again, but not completely, you should get a hook.

- We push the wire under the fittings that need to be connected.

- Next comes the hook itself. It must be inserted into the resulting loop and hook the free end of the wire.

- One turn is made. It is important to keep the free end.

- Pulling the hook over ourselves, we twist the wire until it breaks off.

A step-by-step diagram for performing a simple crochet armature knot.

Note! In order not to buy a crochet hook, you can make it yourself. You will need a piece of steel rod, and the handle can be made of plastic or wood. Having made it once, you can constantly use the knitting tool. See step-by-step instructions for making a hook with your own hands.

"Dead Knot"

This unit is used to reinforce structures consisting of reinforcement bars and clamps, these are beams and columns. Since it securely fixes the reinforcement in the corner of the clamp, the fitters called it a "dead" knot. To perform such a knot quickly and efficiently, you need to practice a lot. Consider the instruction for executing the node:

- We take a wire 20–40 cm long, its size depends on the diameter of the reinforcement used, and bend it in half.

- We run the wire, loop forward, under the bottom of the reinforcement to the left of the clamp, leaving 2–4 cm to complete the knot.

- We bring the wire to the top of the clamp and bend again under the bottom of the reinforcement.

- We insert the hook into the loop and hook the free end of the wire.

- We pull the hook towards ourselves and at the same time make several turns until we feel that the wire is clamped, or until the loop comes off.

Scheme of a ligament of reinforcement with a "dead" knot using a hook.

It should be noted! In order for this knot to securely fix the reinforcement in the corner of the clamp, the wire should be pressed as tightly as possible to the reinforcement and the corner of the clamp, otherwise the tie will turn out to be unreliable.

You can check the quality of the knot by pulling the clamp with your hand, if it staggers, then it is made incorrectly or not fully tightened. We tighten or make an additional tie with a simple knot.

When reinforcing complex structures, such as semicircular beams, nodes can be combined. First, a “dead” knot is made, and then two simple ones crosswise, as in the photo below.

Special knitting gun

For knitting reinforcement - this is an ideal tool. It makes the process much faster and easier. It is most convenient to assemble a metal frame with it. The only caveat is that such a unit is not cheap. That is why it is used on large-scale construction projects. The minimum cost is 30 thousand rubles.

It looks like a normal drill. Only a roll of wire is inserted into it. For knitting, you need to point the gun at the junction and pull the trigger. He will knit himself in seconds. This is the easiest and most affordable option for how to tie rebar.

On a note! It takes 9 seconds to tie a knot with a hook. If you take an automated hook, it will take 7 seconds. And knitting with a gun takes only 1 second per 1 knot.

But this method also has its drawbacks:

- Not everywhere they can be reached to perform knitting.

- Price.

- When fixing the reinforcement, you can no longer untie the knot with a hook.

- You will not knit large diameter reinforcement.

Using a screwdriver with a hook

To speed up the process and make it automated, a modernized screwdriver is used. It is enough to insert a homemade hook into it. A slate nail is suitable for this purpose. It is clamped in a screwdriver and is ready to work.

The principle of its operation is no different from the previous version. The only difference is that the process is much faster. And if the screwdriver has speed control, then it is adjusted so that at maximum tension of the wire it does not break.

Knitting reinforcement with pincers

This knitting method is good because in the process of work the wire is saved, due to the fact that it can be knitted into one, and there is no need to make loops, as for a crochet hook.

Of the minuses, it should be noted:

- Requires more practice for speed knitting.

- The knitting speed is 2 times less than that of the hook.

- When knitting in 2 wires, a hard knot with a sharp end is obtained, it is necessary to wear safety shoes, otherwise you can break your leg.

The video below shows how fast the viscous tongs can achieve, but it takes a lot of practice. Professional fitter, makes a tie in 3-4 seconds.

The choice of wire for knitting reinforcement

Wire is one of the important elements of work. And this means that the quality of the future frame, its strength and speed of work depends on its choice.

According to the building codes of SNiP, as well as the provision from GOST 3282-74, the wire must comply with the prescribed requirements. Here are some of them:

- if the reinforcement has a cross section of up to 12 mm, then a knitting wire with a cross section of 1.2 mm is required;

- if the cross section is from 16 to 18 mm, then the cross section is 1.6 mm;

- with a cross section greater than 18 mm, we use a cross section of 2 mm (or two 1.2 mm each).

Advice from the master! For my 10 years of experience in monolithic construction, I want to say that the most popular and convenient wire for work has a diameter of 1.2 mm. And the most suitable tool for knitting reinforcement is a hand hook, proven by practice.

The reinforcement in the foundation plays an important role - it does not allow the structure to collapse during bending. To connect the rods to each other, you can use one of two methods: knitting or welding. The first method is the most preferable, although it requires a lot of labor. In order to competently perform knitting of reinforcement, you need to familiarize yourself with the technology for performing work.

The connection of the rods to each other in this way can be done in three ways: with a gun, hook or pliers. The first option will allow you to do everything without unnecessary labor and time costs, but will require the availability of special equipment and the ability to handle it.

For knitting reinforcement, knitting wire is used. Clamps must be selected in accordance with GOST “Low-carbon steel wire for general purposes. Specifications". The material must undergo a firing process, which will increase flexibility and simplify the work of knitting a carcass from reinforcement. At the same time, the strength of the clamps for the connection does not decrease, which allows you not to worry about reliability. With a reinforcement diameter for the foundation of not more than 16 mm, it is recommended to use a wire with a cross section of 1.2-1.4 mm. Smaller clamps will not be able to guarantee the strength of the connection, so they are folded several times. It is important to remember that the thicker the wire, the more difficult it will be to bend.

There are no problems when working with a special pistol, but in private housing construction they rarely resort to its help. More often, builders choose crochet hooks. To make a connection, proceed as follows:

- Source materials are being prepared. In this case, it is necessary to cut the knitting wire into pieces 20-25 cm long each and fold them in half.

- The wire is slightly bent and brought diagonally under the intersection of the bars to be connected.

- The hook for knitting reinforcement is inserted into the loop formed when the wire is folded in half. The tool also engages the second end of the fastener. In order for the end not to jump off the hook, it is bent. In this case, it is not necessary to thread the wire through the loop.

- The hook is rotated clockwise, thereby twisting the wire (loop and ends) until it stops. It is important to control the force so that the wire is not damaged or torn. In order for the connection to be reliable, it will be enough to be limited to three or four turns.

- After making the connection, you need to carefully pull the hook out of the loop and move on to the next section.

Scheme of knitting reinforcement.

This technology is used when it is necessary to connect two rods located perpendicular to each other. There are especially many such areas in slab foundations, where reinforcement is made with meshes.

Difficulties may arise when using class A240 smooth reinforcement. In this case, the clamps can move freely, which leads to a decrease in the reliability of the connections and the displacement of the mesh nodes. Regulatory documents do not recommend the use of rods below class A240 for load-bearing structures, therefore, if the standards are observed, such problems do not arise.

To simplify the work, you can make patterns for knitting. These elements work on the principle of workbenches. For manufacturing, take wooden blanks 30-50 cm wide and up to 3 meters long. Grooves and holes are drilled on them, in which the rods will later be fixed. You will need to lay out pieces of knitting wire in advance.

Read more about how to connect reinforcement.

Knitting reinforcement for strip foundation

When reinforcing the structure, it is important to comply with all requirements. The tape should be reinforced with frames. The scheme includes the following types of reinforcement:

- Working. It is accepted depending on the cross section of the foundation and the load on it. For private houses, it is assigned only based on the size of the tape. The total cross-sectional area of the bars is calculated as 0.1% of the cross-sectional area of the reinforced structure. In this case, it is important to take into account the minimum value, which for a tape with a side length of less than 3 m is 10 mm, and for other cases 12 mm.

- Transverse constructive. The minimum diameter is 6 mm.

- Vertical constructive. With a tape height of less than 80 cm, it should be at least 6 mm, in other cases - 8 mm.

When laying the frame, the rules for the protective layer of reinforcement are taken into account, which, according to the "Manual for the design of concrete and reinforced concrete structures made of heavy concrete without prestressing", is taken equal to:

- 40 mm for working reinforcement in the presence of concrete preparation, 70 mm in its absence;

- 35 mm for structural reinforcement in the presence of concrete preparation, 65 mm in its absence.

The strip foundation frame can be assembled in two ways: in a pit or trench and on the surface. The easiest way to control the accuracy and quality of the joints is with the second method. After all the reinforcement elements are connected, the frame is lowered into the recess and set to the design position. When working, it is important to take into account the minimum overlap of the rods when connecting along the length, which is 20 diameters of the reinforcement, but not less than 250 mm. It is important to provide additional reinforcement at the corners of the tape. There are several schemes for making such connections (overlapping, using additional parts), while the step of transverse reinforcement is halved.

One of the possible schemes for reinforcing the corner of a strip foundation.

Read more about how to properly reinforce a strip foundation.

Knitting reinforcement for a slab

The slab foundation, according to the manual mentioned above, is reinforced in such a way that the total cross section of the reinforcing bars in one direction is 0.3% of the cross-sectional area of the slab, the diameter of the bars is at least 10 mm (12 mm with a side length of more than 3 m). In this case, it is important to take into account the height of the structure. If it is 150 mm or less, then one mesh is knitted, in other cases it will be necessary to lay reinforcement in two rows, providing vertical clamps between them.

The work on assembling the reinforcing cage is performed in the following sequence:

Read more about how to properly reinforce a slab foundation.

Knitting reinforcement grillage

The technology here is similar to the strip foundation. The only difference is that it will be necessary to change the reinforcement scheme at the junctions of the grillage and the free-standing support. Reinforced concrete grillage can be installed for various foundations:

- reinforced concrete columnar;

- bored piles;

- screw piles.

In all cases, the fastening of the tape and the support is carried out by releasing the reinforcement. In this case, the frame is knitted so that two rods connect the pile with the lower belt, and two with the upper one. Attaching only to the bottom row is wrong. Reinforcement at the corners and junctions of the walls is carried out in the same way as for the tape structure.

Scheme of the correct reinforcement of the grillage / pile interface.

Read more about how to properly reinforce a reinforced concrete grillage.

If the manufacture of the frame is not carried out independently, but a team of builders is invited, unscrupulous workers may offer to replace knitting with welding. It's not worth agreeing to. This attempt to reduce the complexity of the process and increase the speed of work can lead to a decrease in the strength of the rods at the joints and premature corrosion of the reinforcement.

Advice! If you need contractors, there is a very convenient service for their selection. Just send in the form below a detailed description of the work to be done and you will receive offers with prices from construction teams and firms by mail. You can see reviews of each of them and photos with examples of work. It's FREE and there's no obligation.

The strength, reliability and durability of the foundation support structure largely depend on the quality and correctness of the arrangement of the reinforcing frame. The reinforcing belt can be considered as a kind of skeleton, contributing to a significant increase in the stability of the base to incoming loads.

Reinforcing belt  Reinforcing frame device

Reinforcing frame device

When preparing for the forthcoming pouring of the foundation, it is necessary, firstly, to figure out which reinforcement is expedient and optimal to include in such a structure, and secondly, in what ways can the individual elements be connected into a single frame.

You are invited to read the information regarding the listed points and important related nuances below.

fiberglass frame

fiberglass frame

Diameter

When choosing reinforcement for the foundation, first of all, pay attention to the diameter of the rods. The dependence is simple: the thicker the reinforcement, the more serious loads it can withstand. When determining the optimal diameter, first of all, the characteristics of the soil (the main point is heaving) and the estimated weight of the finished building, taking into account the mass of its internal arrangement and residents / visitors, are taken into account.

Rebar diameter, mass, total cross-sectional area

Rebar diameter, mass, total cross-sectional area

This is how it should ideally be. Along with this, many private developers refuse to draw up project documentation and perform related extensive calculations, adhering to average and generally accepted values. In the case of the construction of relatively small buildings, for example, such as a bathhouse, such an approach is acceptable.

Class

The second important indicator is the class of reinforcement. For a private foundation, class A-3 material is suitable.

Corrugated fittings A3 steel grade A500C, GOST 5781-82

The fittings of this group are very convenient in work (it easily bends without the use of special tools), durable and reliable. Less commonly used rods of class A-2 (they can be bent 180 degrees, A-3 - 90 degrees).

Material

An equally important indicator is the material of manufacture of reinforcement. Previously, there were no questions regarding this point - the bars were made of durable steel, there were no alternatives.

However, the construction market is constantly developing and expanding. One of the confirmations of this was the appearance on the sale of fiberglass reinforcement.

The rods of this group are characterized by improved operational and practical characteristics. Among the main advantages of fiberglass reinforcement, the following points should be noted:

- high indicators of reliability, strength and durability;

- relatively low cost;

- light weight.

The use of fiberglass reinforcement allows you to save on average up to 30-40% on the purchase and transportation of material for arranging the reinforcing frame compared to more traditional steel elements.

The light weight of fiberglass reinforcement makes it possible to transport it in a simple car. The armature has no restrictions on length. An ordinary grinder is used for cutting rods.

Important! Before cutting fiberglass rebar, be sure to wear protective overalls, gloves, goggles and a respirator.

Fiberglass reinforcement of various diameters is available for sale, involving the use of different knitting options. Predominantly for longitudinal reinforcement, 8 mm rods are used, for transverse - 6 mm.

The fastening of fiberglass reinforcement is most often performed in 2 ways:

- using a knitting wire;

- with plastic clamps.

The procedure for implementing both methods remains identical for steel and fiberglass reinforcement and will be discussed in the relevant sections.

Prices for fiberglass reinforcement

fiberglass reinforcement

Wire, clamp, retainer: features of existing fasteners

The fastening of reinforcing bars into a single frame can be carried out using wire, clamps and special clamps. About them in the table.

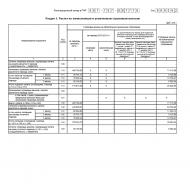

Table. Materials for fastening reinforcement

| Bonding material | Description |

|---|---|

| The most traditional, budgetary and familiar (especially for builders of the "old school") material for knitting reinforcement. Made from annealed steel. Sold mainly "wholesale", ie. in packages (more convenient, because the material is already cut into pieces of a suitable length) or special coils. The weight of the package and the length of the wire pieces may vary depending on the manufacturer. The most convenient are 5-kilogram packs filled with 40-centimeter pieces of wire. One such package usually contains from 1000 to 1500 pieces of wire. |

|

| According to the principle of use, it is not much different from a knitting wire - the same methods, similar tools. It is characterized by great ease of use (easier to bend and twist). It costs a little more than wire. It has an increased diameter (an average of 4 mm versus 1.2 mm for the wire). To ensure a reliable connection of the reinforcing bars, it is enough to use a 20 cm clamp per intersection point. | |

| The most modern version of the connection of reinforcing bars. The fasteners are made of plastic. They perform best in combination with fiberglass reinforcement. The advantages over steel reinforcement and knitting wire are obvious. To fully understand them, you need to pay attention to only 1 drawback of steel reinforcement - it is subject to corrosion. Rust can increase the diameter of a metal bar by an order of magnitude. Its strength, however, does not change for the better. Corrosion leads to the appearance of pores in concrete. Water enters the pores. In winter, the water expands and increases the size of the cracks. The clamps do not rust, and it is much easier, more convenient, and faster to connect reinforcement with their help than with wire. Several types of fasteners are available for sale, allowing you to connect reinforcing bars in various spatial directions, equip “stands” (as in the image) and solve other tasks related to reinforcement. |

Due to the fact that the guide in question is devoted specifically to knitting reinforcement, the order of connecting the rods with special clamps will not be considered - this process is not viscous in the traditional sense and is generally intuitive.

Wire and clamps should be given more attention.

First, the wire.

For the manufacture of such, as noted, low-carbon steel grades are used. The annealed material is relatively easy to bend and does an excellent job with the tasks assigned to it. Non-galvanized knitting wire (black) and its galvanized counterpart (white) are available for sale.

Many masters consider the purchase of galvanized knitting wire for arranging the foundation to be an excess and an inappropriate waste of money, arguing that the reinforcing frame becomes inaccessible to air after pouring concrete, therefore, nothing will rust. Along with this, it is impossible to exclude the occurrence of corrosion, as noted earlier.

- if you decide to use steel reinforcement, you can knit with both galvanized and non-galvanized wire - if corrosion gets to the reinforcing frame, it will not matter what “is”, at least reinforcement, at least wire, and it will not be possible to avoid deterioration in the quality characteristics of the foundation under such circumstances ;

- if it is decided to use fiberglass reinforcement, it is better to knit with galvanized wire - this will minimize the risk of corrosion and ensure a longer service life of the supporting structure.

As for the diameter, the most optimal in terms of ease of use and reliability is the 1.2-1.4 mm version. The "one" is weak for the foundation, extra effort will be spent on working with the "two".

Second, clamps.

This, as noted, is a modernized and improved version of the binding wire. They are made of plastic, not steel, so when using such fasteners, the likelihood of corrosion inside the supporting structure is excluded. Along with this, it is precisely because of the material for the manufacture of plastic clamps that many developers have a number of well-founded questions regarding the fasteners of this group.

- Will the clamps be able to withstand the loads created inside the foundation? Can.

- Will the fasteners break over time, violating the uniform distribution of loads and, in general, worsening the quality of the foundation? Will not break.

- Is a plastic clamp really reliable? Indeed, but you need to correctly approach the issue of his choice.

Useful advice! For knitting reinforcement, plastic clamps using steel wire as a core are best suited. Such clamps are more expensive than steel wire, but they do not occupy the convenience in work.

Important note! Plastic clamps cannot be used for knitting reinforcement when carrying out work on arranging the foundation in winter - in the cold, the material for making clamps becomes brittle almost instantly. The exception is special clips made of polyamide.

knitting wire prices

knitting wire

First, remember the main rule: reinforcement is not connected by welding, but it is connected.

Rebar bonding - diagram

The bottom line is this: the contact of the metal with the electrode helps to reduce the strength of the first so that even the loads that occur with the minimum possible shrinkage of the foundation can lead to catastrophic consequences, the sequence of which is usually as follows:

- the joints of the reinforcement are destroyed;

- the reinforcing frame disintegrates;

- the concrete structure begins to crack.

What it threatens the structure erected on the foundation does not need comments. As an exception, only special reinforcing bars can be considered, the manufacturing technology of which, according to GOST, initially implies the possibility of subsequent welding.

Secondly, vertical support rods that are installed as supports for horizontally oriented bars cannot simply be driven into the ground. It is correct to do this: the lower reinforcing row is laid on special plastic clamps (the so-called “cup holders”, demonstrated earlier), and the upper part of the vertical rods is connected to the upper row of the frame. Such placement will exclude the contact of the rods with the external environment.

Thirdly, the upper horizontal row of the frame must be tied from the inside - this is more difficult, but more correct. Often, uninformed developers make the mistake of leaving the top row of the frame unfixed. If concrete is poured manually, nothing bad will happen in such conditions. When pouring with a special concrete pump, the mixture is supplied under pressure. The pressure created will push the reinforcement apart, causing the wire to burst.

Fourthly, when performing reinforcement, special attention should be paid to the corners of the structure, because. they are the weakest point of the foundation. In such areas, the rods do not fit at right angles, but are bent. The overlaps, at the same time, are hidden in the wall. It is important that adjacent reinforcing bars do not overlap at one point. The principle is shown in the image.

Reinforcement is considered correct, as a result of which a rigid spatial frame is obtained that can withstand the weight of a person without visible changes in the structure.

Prices for plastic retainer for fittings

plastic rebar clamp

For knitting reinforcement, you can use a wide variety of devices - from pliers to special automatic pistols.

The use of pliers and wire cutters with pre-blunt teeth is the most primitive option. Its only advantage is the absence of the need to purchase additional devices, however, twisting the wire with such improvised means is long, inconvenient and tiring. Therefore, we will refrain from considering them.

If you are on a budget, make at least an elementary homemade crochet hook. To do this, you will not need anything other than a nail with a diameter of 4-5 mm, a blank for a pen or an old unnecessary screwdriver / awl and a hammer.

To make a hook, do the following:

- prepare a pen. You can use any suitable wooden blank (it is more convenient and easier to drive a nail into wood), for example, from a used home tool. The handle can be made from other materials, the main thing is that you feel comfortable using it;

- drive a nail into the handle, leaving 3-4 cm free;

- cut off the head of the nail, for example, using wire cutters or other suitable tool;

- bend the nail into a hook. This is done as follows: you put the nail on a suitable stand, for example, a brick, and gradually use a hammer to shape the workpiece into a crochet hook.

The procedure for making a hook from a screwdriver / awl is reduced to the last step of the above guide. At the output, you should get a device that looks something like the following.

Knitting with a regular crochet

Having prepared a homemade hook or bought a ready-made tool in a hardware store, get to work. To begin with, carefully practice on third-party pieces of reinforcement until you thoroughly understand the principle of operation. It consists in the following:

- a piece of knitting wire with a length of at least 200 mm is folded in half;

- the resulting workpiece is wrapped diagonally at the point of connection;

- the hook is threaded into the created loop;

- the free ends of the binding wire are gently pulled through the loop. The hook also helps at this stage;

- without taking out the working tool, it is turned clockwise until a reliable connection is obtained. Usually a few (up to 3-4) turns are enough. Do not twist the wire too much - it will break. Bend the excess parts of the ends of the wire. If the ends are too long, you can cut them off with wire cutters or other suitable tool.

The process is shown schematically in the following image.

For a better understanding of the technology, check out the step-by-step illustrations.

There are several other options for crocheting rebar, but the above method is the most reliable, it is recommended that you stick to it.

Also, the method in accordance with which the performer must sequentially perform the following manipulations performs well:

- fold the piece of wire in half, as in the previous case;

- bring the folded wire under the reinforcement at the junction;

- grab the loop with a crochet hook;

- bend the remaining free “tail” through the hook;

- twist the resulting loop.

The procedure for performing work in accordance with this method is shown in the following illustrations.

Video - Crochet reinforcement

Knitting with semi-automatic crochet

The semi-automatic, also reversible and screw hook, is an improved and more convenient version of the above device.

The length (as a rule, it is 32 cm) and, in general, the design features of the reverse hook allow for high-quality twisting of the wire with one tightening. The soft rubber handle makes working with the tool even more comfortable and safe, eliminating the possibility of blisters on the hands.

The procedure for using such a hook is as follows:

- the performer circles the reinforcing bars with wire at the junction (the procedure is the same as in the case of using an ordinary hook, all the necessary information was given above);

- the hook is inserted into the loop;

- the performer pulls the handle of the instrument towards himself.

That's all. As a result of such simple actions, the device, which works like a spinning top, quickly tightens the wire, ensuring a tight, reliable and neat knot. Labor intensity and time spent on work are reduced significantly.

The tool is suitable for both professional and private use. The reversible hook does not need any special maintenance - it is enough to periodically lubricate the working elements with oil.

The principle of operation of a screw crochet hook is demonstrated in detail in the following video.

Video - Knitting with a semi-automatic crochet

Crocheting by hand is a rather protracted and laborious undertaking. And although the semi-automatic hook, discussed in the previous section, can significantly facilitate and speed up the implementation of reinforcing work, there is a great opportunity to do everything much faster and with even less effort. A drill driver will help with this.

All you need to do is make a hook (an ordinary nail with a diameter of 0.5 cm is suitable as a workpiece, you have already familiarized yourself with the principle of making a hook in one of the previous sections) and fix it in the screwdriver chuck in the same way as ordinary drills are installed ( in detail, the sequence for replacing the working tool should be clarified in the instructions specifically for your screwdriver, because for different models of tools, these points may vary slightly).

Such a design will look like this.

The further procedure does not differ from the technology of crocheting reinforcement: you still fold the wire in half, wind it under the reinforcement, grab the loop with a hook, but twist it no longer manually, but with a screwdriver, applying minimal effort.

When twisting the wire, the tool experiences practically no load, so even the most budgetary drill-driver with a minimum power can be used for knitting. It is better that the model is equipped with a rotation speed controller. Before work, set it to a minimum.

Video - Knitting reinforcement with a screwdriver

The gun makes rebar tying as fast, simple and convenient as possible - the most advanced models of such guns are able to create a connection in less than a second. No preparatory measures are required: the wire is wound on the gun spool, the user simply brings the tool to the junction and presses the appropriate button. For information on special options and functions, please refer to the instructions for the specific instrument.

It looks like this.

There is no need to cut the wire before work: the tool will do everything on its own. This is a big advantage - there is no waste in the form of scraps of binding wire, so that the amount of unnecessary costs and operating costs is significantly reduced.

The gun is easy to use - it can be held with one hand, the second, while holding the reinforcing cage, which eliminates the need to attract additional labor in the form of assistants.

An automatic gun, in contrast to hand tools, allows you to count on a constant high quality of knitting. By default, all models have the functions of adjusting the length of the segments and the tightening force.

| Pistol brand | Weight | Rebar size | Price |

|---|---|---|---|

| 1.4 kg | D19хD18 | RUB 48,780 | |

| 1.5 kg | D20хD22 | RUB 60,920 | |

| 2.25 kg | - | 52 000 rub. | |

| 2.4kg | from 20 to 35 mm | RUB 165,000 |

Among the disadvantages of an automatic gun for knitting reinforcement, the following points can be distinguished:

- high cost of tools and accessories (wire spools);

- the need for preliminary training in working with a gun (in general, nothing complicated, but the extra time is still spent. In practice, it is more than offset by the savings in time spent on twisting the wire);

- the impossibility of using the gun in hard-to-reach places. Even with such a serious assistant, you still cannot completely abandon the use of hand tools for knitting. For example, with a gun it will not be possible to tie the bars in the corners of the reinforcing frame. In addition, you can only slip the hook between the whips to tie the 2nd layer of the reinforcing frame.

Video - Knitting reinforcement with a gun

A few words about collars

For knitting reinforcing bars, as noted, you can use special clamps. They look like this.

Thus, one end of the clamp is free, and the latch is located on the second.

The procedure for using the clamp is as follows:

- the product is brought under the reinforcing bars at the intersection;

- the free end is pulled into the hole of the latch until it stops;

- the position of the fastener is fixed, due to which the connection of the reinforcement is ensured.

There are many types of clamps available on the market. In combination with fittings, products made of polyamide 6.6 perform best. Such clamps “feel” normally in the temperature range of -40-+85 degrees, without bursting, cracking or spreading. A good collar should be flexible. You can check this parameter as follows: take the product and bend it in half. If a crack appears at the bend, do not use such a clamp.

Special pistols are available on sale to make the process of arranging clamps easier and faster.

Prices for cable ties (clamps)

cable ties

Video - Knitting reinforcement with clamps

Similar fasteners include metal clips (connectors) for connecting reinforcing bars into a single frame. One end of such a net is equipped with a hook, the other with a loop. The diameter of a steel clip is on average 2-4 mm. At the place where the reinforcement is connected, the hook and loop engages on the lower steel rod. The middle part of the latch presses the upper rod to the underlying one.

Knitting reinforcement with a paper clip

Knitting reinforcement with a paper clip  Clips for knitting reinforcement

Clips for knitting reinforcement

Successful work!

Video - Do-it-yourself knitting reinforcement for the foundation

Reinforcement of reinforced concrete structures is a key factor determining their reliability and durability. Concrete structures are reinforced with reinforcing cages assembled using a knitting wire, which we will talk about in this article.

The publication presents the wire for reinforcement, considers the scope of its use, varieties and features of the application. Instructions for calculating the consumption of material and recommendations for its selection are given.

1 Knitting wire - where and why is it used?

Reinforcing wire is used in the field of individual and industrial construction for the manufacture of frames used to reinforce reinforced concrete structures. By means of a knitting wire, adjacent bars of reinforcement are connected at the place of their overlap.

The material can be used in the assembly of the following types of frames:

- foundation (tape, monolithic, columnar);

- floors (basement and interfloor);

- floor screeds.

The most common wire for reinforcement in monolithic construction. In the industrial production of reinforced concrete products - piles, floor slabs, reinforced concrete blocks, their frames, in order to save time, are joined using spot welding.

1.1 How to calculate material consumption?

According to the provisions of SNiP, the consumption rate of the binding wire during the assembly of the reinforcement cage is 30 cm per connection or 4 kg per ton of rebar. To find out how much material you need to use, you need to determine the number of rebar connection points in the frame and calculate the total consumption.

As an example, we give the calculation of wire consumption for reinforcing a tape-type foundation. We use the conditional size of the foundation 5 * 6 m, it will have 2 belts of longitudinal reinforcement - upper and lower, 3 bars each, connected by vertical and transverse lintels with a step of 40 cm.

Flow rate determination algorithm:

- We calculate the perimeter of the frame: 5 * 6 \u003d 30 meters.

- We determine the number of jumpers based on a step of 40 cm: 30 / 0.4 = 75 pcs.

- There will be 6 docking points on each jumper (3 bars on each belt), we determine the number of connections: 75 * 6 = 450 pcs.

- We calculate the consumption of knitting wire: 450 * 0.3 \u003d 135 m.

In total, to connect the frame bars, we need to use 135 meters of material. Similarly, by determining the number of connections and multiplying them by the normative consumption, it is possible to calculate the total consumption of wire for assembling a reinforcement cage of any configuration.

2 Classification and varieties

Wire for reinforcement is classified into varieties according to such parameters as:

- the presence or absence of a protective coating;

- heat treatment;

- strength class.

Depending on the presence of a protective coating, the material is divided into two varieties: made from ordinary and. The coating is applied by hot dip galvanizing, which involves curing coils of wire in baths of molten zinc.

Material with a protective coating is divided into two classes - 1C and 2C. The differences between them are in the thickness of the galvanized layer, in class 2C material the protective layer is much thicker: for comparison - 155 against 85 g / m 2 in a wire with a diameter of 6 mm. An alternative to galvanized materials is MNZhKT wire made of copper-nickel alloy, however, its use in construction is unjustified due to its high cost.

According to the type of hardening, the reinforcing wire is classified into raw and annealed (it has the letter O in the marking). The essence of heat treatment is to heat the material to a predetermined temperature in a blast furnace and then cool it down. As a result of annealing, the crystal structure of the metal changes and the internal stress of the steel is destroyed, which provides increased elasticity and mechanical strength of the wire.

Depending on the strength class, products are classified into two groups B-1 (normal) and B-2 (high-strength). The difference between them lies in the brand of alloys used, for the manufacture of V-1 wire low-carbon steel is used, for V-2 - steel with an increased number of components. Material V-2 is used to connect frames made of prestressed reinforcement, while class V-1 is intended for the installation of non-stressed structures.

2.1 Dimensions and weights

The diameter of the material depends on the presence of a protective coating - galvanized wire is available in diameters of 0.2-6 mm, uncoated - 0.16-10 mm. Products are delivered from the factory in coils (weight from 15 to 250 kg) or coils (500-1500 kg). The coil should consist of one piece of wire, the coil - no more than 3.

Here is a table of knitting wire weight 1 meter, BP brand, the most popular on the market:

- VR-1 (diameter 1 mm) - weight 0.012 kg;

- VR-2 (diameter 2 mm) - weight 0.025 kg;

- BP-3 (diameter 3 mm) - weight 0.06 kg;

- VR-4 (diameter 4 mm) - weight 0.1 kg;

- VR-6 (diameter 6 mm) - weight 0.23 kg.

A characteristic feature of the BP brand is the presence of corrugated walls, due to which the adhesion (adhesion) of the material with the reinforcement bars increases, which positively affects the overall strength of reinforced concrete structures.

Wire "Cossack

"Recently, a wire for knitting reinforcement with rings, also called "Kazachka", has become widespread on the market. It is produced in the form of lengths of 8, 10, 12 and 14 cm, at the ends of which there are rings for a knitting hook. The connection of reinforcement with "Kazachka" is carried out much faster than with a standard analogue, since there is no need for cutting and self-forming rings. The material is supplied in the form of bobbins, consisting of 1-5 thousand pieces.

2.2 Knitting reinforcement with wire (video)

2.3 How to knit?

To assemble the frame from reinforcement bars 10-14 mm, you need use wire with a diameter of 1.2-1.4 mm. If the material has poor elasticity, the coil must be kept for 20-30 minutes in a fire, and then allowed to cool at natural temperature. It is possible to use products of smaller diameter, however, in this case, when making the connection, you will need to bend it twice.

There are only two ways of fastening the reinforcement in the frame: electric welding and knitting. We will not open a discussion about which one is preferable. Let's just say that when knitting, the strength of the working rods does not decrease.

Any welding weakens the metal, as it creates local stresses in it. This negatively affects the reliability of the entire structure.

Compared to welding, knitting is more labor intensive.

Despite this, in private construction with its small volumes, it is better to choose them. Especially when it comes to such critical structures as foundations and floor slabs.

In this article, we will tell novice builders how to properly knit rebar. Consider the tools, materials and technologies used for this work. We hope that the information received will help you to handle metal with confidence, assembling strong and reliable frames.

Reinforcement knitting methods

There are two ways to fix reinforcing bars: manual and automated.

The manual method uses four types of tools:

- pliers;

- Hook (simple and reversible);

- Screwdriver with nozzle.

Using pliers is not very convenient. Therefore, they are rarely used and only for the assembly of small frames. Crochet is used more often. This simple device, with a certain skill, helps to quickly connect steel rods.

There is an improved modification of a simple hook (reversible). Its basis is a screw that rotates when the handle is pulled back.

By combining a hook with a screwdriver, home craftsmen have created another convenient device for fixing steel bars in the frame.

Automated knitting is performed by the so-called gun. This is a rather complex and expensive device used in large facilities. Its performance is such that one knot is tied in 1 second.

The device is equipped with a compartment in which a wire reel is installed. The working body of the gun delivers it to the armature and ties it into a knot.

Crochet technology

There is nothing difficult in this operation. Having done it several times, you will quickly "fill your hand."

The essence of the method is as follows: the intersection of the rods is covered with steel wire folded in half. The crochet hook is inserted into the loop and the other free end is captured with it. After that, the tool is rotated until the moment of contraction. The ends of the wire are bent inside the frame.

Masters know one little secret that guarantees tight contact: without twisting the loop a little, you need to pull it towards you and only after that tighten it to the end.

Scheme of knitting reinforcement with a hook

Working with a screwdriver has no fundamental differences from crocheting. The advantage is higher speed and less labor intensity. When using a screwdriver, do not forget to set the rotation speed of its cartridge to a minimum.

Reinforcement should not be knitted with an electric drill. The large inertia of this tool does not allow you to accurately determine the moment of completion of the tightening.

Methods for connecting steel rods and the main types of nodes are shown in the diagram below.

materials

To assemble the frame, a special annealed wire is used. It is durable yet soft enough. This allows you to tighten the knots without risking tearing it. The recommended diameter of this material depends on the cross section of the reinforcing bars and ranges from 1.0 to 1.4 mm.

Cheap wire comes uncoated and is called black. More resistant to corrosion has a protective layer of zinc.

Knitting wire is produced in two versions: in coils and measured (in segments). Working with a skein is more difficult, since it has to be manually cut into pieces. Measured material can be put into action immediately. Especially convenient is the wire, which has loops at the ends.

Norms and rules for the performance of work

Guidelines for the design and manufacture of reinforcing cages are contained in two regulatory documents. GOST 10922-2012 specifies technical conditions for knitted and welded joints of reinforced concrete structures. Set of rules SP 52-101-2003 regulates the requirements for the design of frames.

Based on these standards, standard schemes for tying reinforcement under a strip foundation, overlap sizes, diameters of the reinforcement used and other rules for the production of work have been developed.

When joining rods on straight and corner sections, the length of the overlaps is important. SNiP sets this parameter depending on the diameter of the working reinforcement (in millimeters):

- 300 mm for bars with a diameter of 10 mm;

- 380 for 12mm;

- 480 for 16mm;

- 580 for 18mm;

- 680 for 22mm;

- 760 for 25 mm.

Knitting the frame of the strip foundation

At the bottom of the trench, on stands (bosses) 4-5 cm thick, the estimated number of longitudinal rods (diameter 12-18 mm) is laid. The distance between them depends on the size of the foundation and can be from 5 to 20 cm. If the standard length of one steel bar (6 meters) is not enough for the entire “tape”, then several rods are used. They are connected to each other, observing the normative overlap.

Stands for reinforcing cage

Clamps made of smooth or corrugated steel with a diameter of 8-10 mm are vertically attached to the working bars. The step of the clamps according to building codes should be at least 3/8 of the height of the foundation (20-50 cm).

Having installed the clamps, the upper belt of the working reinforcement is attached to them with wire, observing the design distance between the rods.

At the corners and junctions, clamps are placed more often (1/2 step), and the working reinforcement is bent, connecting with the rods of the intersected section of the "tape".

The length of the bend must be at least 50 diameters of the working reinforcement.

Making a reinforcing cage in a trench is a laborious and inconvenient job. Therefore, experienced builders use such a simple device.

Having laid the longitudinal whips on wooden stands, clamps and the lower belt of working rods are tied to them. The finished structure is transferred and placed in a trench.

The assembly of the reinforcing cage of a monolithic slab is simpler than that of a strip foundation. The design here consists of two flat grids. The lower rods are laid perpendicularly with a given step and connected to each other. Then, at the points of their intersection, stands made of steel bars are placed and the upper mesh is screwed to them.

Stand for mounting the upper frame of a monolithic slab

In recent years, fiberglass reinforcement has been used to assemble frames.

You can knit it in several ways:

- annealed steel wire;

- plastic ties-clamps;

- plastic clips.

Estimated prices

The cost of knitting reinforcement, as the estimators say, "sits" in the total price of 1m3 of reinforced concrete. In square or linear meters, it is considered individually for each type of construction. In this case, it is necessary to take into account various parameters (the width and height of the grillage, the thickness of the slab, the cross section of the reinforcement, the level of complexity of the frame, etc.).

For an approximate calculation, builders use the price in rubles per 1 ton of metal used. Today, in 2017, it averages from 20 thousand rubles.