The technology of insulation of the pile-screw foundation. Foundation insulation on screw piles: Important, tips, features

Preface. We will analyze such important question For owners of private houses on complex soils, like insulation of the foundation on screw piles with their own hands. This type of foundation is popular because of its simplicity and lack of earthworks during installation. But the use of this foundation makes it makes it possible to decide how to insulate the space between the house and the soil, how to properly insulate the foundation with the screw pile.

Do I need to warm the foundation on screw piles

The foundations on screw piles are used as the most durable structures during construction on weak bunched and swampy soils, with high levels Groundwater. main feature foundations and structures on the screw piles, in the open space between the floor of the first floor and the soil, so independent work on the insulation of the foundation on the screw piles for the winter is distinguished by certain difficulties.

This foundation is a construction from the piles of bewbled into the soil, a timber or metal beams are used for painting, which and the entire load from the house lies. Effectively use of this design when erecting wooden and frame houses on complex soils. But is it worth insulating the foundation from screw piles? To deal with this issue, you should consider in more detail this design.

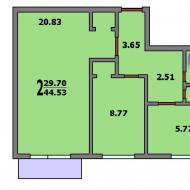

Foundation device on screw piles

The piles of the foundation are a metal pipe with a diameter of up to 300 millimeters and up to 9 meters long. The thickness of the pipe walls is from 8 to 12 mm. The piles of metal blades are ends, which are drilled by the ground when installed and are in the further supports of the pipes. On top of the pile have "Hats", which are used for mounting the framework of the foundation (jumpers from a bar or chawls between pile).

Before mounting the foundation, it is necessary to explore the soil on the site, undesirably the presence of solid rocks that interfere with the screws of the piles. You should calculate the load of the walls of the house on screw foundationTo correctly choose the required amount of piles. The depth of the embedding will depend on the maximum depth of the primer of the soil, the height of groundwater, which also affects the selection of heat-insulating materials for the design.

When screwing down the piles to the ground, it is necessary to fit the tops of the pipes using the level, under the level for stacking asterks (jumpers). Pipes after alignment should be poured with cement mortar, which will increase the strength of the entire structure with a possible bent of the soil. Then, with the help of welding on piles, the headings are mounted and the framework of the frame (beams), connecting all the piles of the foundation around the perimeter.

How to insulate the foundation on screw piles

In a private house and in the apartment, the main condition of a favorable microclimate is a warm floor on the first floor. The main disadvantage of the foundation with screw pile is the open space under the floor, which will lead to a large heat loss in winter without high-quality thermal insulation. The insulation of the basement at home: base, floor and soil is necessary to protect the house from the flow of cold air.

Since the insulation will come into contact with the wet soil, it is necessary to choose heat insulation for the foundation from screw piles, which is not afraid of high humidity, and in which insects or rodents will not start. During the work, there is a need to create a frame that replaces the base of the house, insulation of this design outside or from the inside with the subsequent trim.

If you have chosen mineral wool for work, you should carefully protect the Minvatu layer of waterproofing. When using foam plastic, the insulation should be protected from mechanical damage, ultraviolet and rodents. When insulating the pile of screw foundation, the penplex will require only decorative finish, since the PESEROPLEX is a durable material that is not afraid of moisture and rodents.

How to insulate the pileno helical foundation with their own hands

The process can be divided into 5 main stages: waterproofing of the metal structure, the manufacture of the frame for fastening the heat insulation, the installation of the insulation with the waterproofing film, if necessary, fastening the decorative panels on the base of the house, the device of the warmed gear around the perimeter of the house, dumping the ground or clay inside the foundation of the house. Consider further details these stages.

1. Waterproofing of the pile foundation

Regardless of the stuffing material - wood or metal, careful waterproofing is necessary so that the moisture from the soil penetrates into the design, leading to the corrosion of the metal and rotting the tree. It is necessary to protect with rolled or liquid waterproofing all parts of the structures where thermal insulation will be produced. The tree should be treated with antiseptics, and the metal frame to be treated with bitumen mastic.

To create a heat-saving facing between the soil and the facade of the house, it is necessary to create a structure that imitates the base of the house. You can make this design from easy brick masonry On a finely remedy foundation. The brick base is insulated outside the plates of foam or polyplex and siding or paneling. You can create a frame from a bar or metal guides.

2. Production of base house

Photo. Solar scheme pile Fundament

To make a brick base, it is necessary to pour a small-breed reinforced foundation up to 20 cm. After the concrete is frozen the base of red bricks. The mounting plates of thermal insulation outside is carried out on the brick masonry by mounting foam and glue for polystyrene foam. Insulated brickwork, the pile foundation is trimmed with decorative panels imitating natural stone or brickwork.

The second method, a frame of a timber or metal is a simpler and inexpensive method. It consists in the attachment of horizontal guides to piles with bolts or welding. Between the guides are fixed insulation plates, joints should be treated with mounting foam. Next, decorative panels or siding are mounted on the headings outside. On our site you can calculate the thickness of the insulation for the base on the heat engineering calculator.

3. Heat insulation base house

With independent insulation of the Facade of Minvata or the base of the house on the pile, screw foundation between the guides, leave a distance of 10-15 mm less than the width of the insulation. In this case, the Ministry of Service will be tightly sitting between the guides, not leaving the cold bridges. Mineral wool should be closed by waterproofing, we remind that laying vapor barrier to the insulation should be the right side.

When the foundation is insulated on the screw piles of the penplex or polystyrene foam, the seams between the plates should be properly made by mounting foam. If the characteristics of the inferno ensure that the material does not absorb moisture and will not suffer from rodents, the plates of foam should be protected from rodents and possible mechanical damage. Lincing the insulation on the base of the house can be vinyl or metal siding.

4. Fastening decorative panels

For the cladding of the base, it is necessary to fix on the level of the starting profile for siding all over the perimeter of the house. Then from the bottom up from the starting profile the siding panels or decorative PVC panels are attached. This facing material will keep the insulation on the pile foundation from precipitation, mechanical damage and penetration of rodents. Do not forget to carry out additional waterproofing the facade for siding.

5. Sweep ground or clay

Photo. Production in the base of the house (VENT. Holes)

From the inside, the warmed pileno-screw foundation can be squeezed with soil or clay - this will additionally warm the underground space of the house. Outside the building should be arranged with a warmed celestone to reduce the fruit of the soil under the house and reduce the heat loss of the house in the heating period. In opposite sides of the base, there should be ventilation holes (produced), closed from rodents and insects with lattices.

Warm floors in your home - the key to a healthy and comfortable atmosphere. According to the laws of physics, the heated air accumulates under the ceiling.

But the lower room remains cold, even if it is heated well. Reliable capital foundation, of course, will protect against dampness and drafts, but only partly.

If the house stands on screw piles, there is no continuous ground part of the base. Therefore, cold air and wind passes between the soil and structure. Based on this, the insulation of the foundation on the screw piles must be done necessarily.

The main disadvantage of such structures is an open space where heat is not held. The thermal insulation of the bases of this type differs from the usual process, and has a number of nuances, which we will talk more about.

What materials can be used

- Most often, the insulation of the pile-screw foundation is carried out by applying foam. The material is inexpensive, very lightweight, has a number of wonderful characteristics. Insulation is performed as follows: Sheets are glued to the foundation around the perimeter. As glue use bitumen mastic. Polyfoam is tightly pressed, trying not to leave the gaps and cracks. If so are still formed, they are filled with usual.

- No less effective as the insulation of the screw foundation, the penplex. And for some properties, he even exceeds foam. Such a thermal insulator is durable, racks to moisture exposure, easy to install. It is attached to the painter with a special glue.

- Penodoneglo, extruded polystyrene foam and aerogel. The advantages of them are that when applied, it will not be necessary to make additional waterproofing. These materials themselves have excellent waterproof qualities.

Insulation work

The phased performance can be divided into the following steps.

Stages of insulation

- Waterproofing woodwork and pile racks.

- The frame is assembled - a design that replaces the base and serving the basis for finishing.

- Installation of decorative finishing material based on.

- Installation of insulation from the inside of the entire design, eliminating the slots and gaps between the sheets.

- Plipping with clay, rubble or soil of the basement, to strengthen it.

Installation of thermal insulator

Wooden woodwood impregnation with waterproof mastic

- Before insulation of the pilenor of the screw foundation, it is necessary to think about the waterproofing of the frame. Ruberoid is labeled between its upper surface and the bottom of the walls. It is also placed between the pile end and the bottom bundle of supports. Everything that remains unlocked, namely, part of piles and woodlock is covered by a special waterproof mastic.

- Next, you can mount the insulating layer. If your finances do not allow you to purchase materials, you can do it with your own hands, with the help of remedies, do the following: Fall over the perimeter the foundation of the soil.

Note! This is affordable, cheap, but ineffective method. In this way, you will simply achieve partial sealing of space, there will not be a strokes and floors in the house will become a little warmer, but you can not wait for the desired result. Therefore, it is better to purchase a material that has a low price, but good indicators.

- Polyfoam or its analogues just possess all these qualities. From the bottom of the woodworking to the first floor of the house laid thermal insulation. It should be noted that there should be a gap between waterproofing and thermal insulating operations. This is necessary so that glue or mastic is completely dried.

- The next, the last step, can be considered final finishing work. After all, the insulation needs to be protected not only inside, but also outside, and the finish will carry a decorative function. One who is familiar with construction and knows how to insulate the foundation on screw piles will advise you a lot of materials suitable for these purposes.

The most inexpensive and simple finishing materials can be ranked a conventional profiled sheet. But it is not attractive enough, so if you have the opportunity, you can purchase analogues. Moreover, the range of facade materials offered today is very diverse (read also an article).

It can be a decorative brick, stone or their imitation, tile of various sizes, colors and structures, front panels. They often make the insulation of the loggia from below, balconies, and other types of outer walls.

To the top of the piles, a special frame is mounted, it will serve as the basis for the future finish. It is attached to your selected material.

Imitation soccer

Cap of bricks

The pile designs have one, a significant drawback - the house is raised above the ground, and does not have a full-fledged base. In wetlands, or where the properties of the soil do not allow the usual house, it is necessary to build on screw piles.

If you have this type of structure, it is desirable not only to insulate it from the bottom, but also to make the skin imitating the base. Instructions for acquired materials will tell in detail how to use them. Ultimately, after small labor costs, you will get and warm floors in the house, and full, finished appearance the buildings.

The imitation of the base can be made from ordinary brick, eating a light wall around the perimeter of the structure of the structure. But it will cost a little more expensive than just a frame with insulation and trim.

Note! For greater comfort in the house there is not enough to equip its capital bottom. To keep warm, it is also necessary to produce insulation plastic windows, Operactions in the doors coming out the walls. Only then will you get the maximum result.

Output

Specialization: finishing of facades, interior decoration, construction of cottages, garages. Experience and gardener and gardener experience. There is also experience in repairing cars and motorcycles. Hobbies: the game is not a guitar and a lot more, to which there is not enough time :)

The pile foundation, unlike the belt, has no solid surface, so at home masters, his insulation causes a number of questions. In fact, nothing complicated in this procedure, the main thing is only to comply with some technology. Therefore, below you will tell you in detail how the pile foundation correctly insulate that the floor is warm, and under the house there was no damp.

Why insulate the pile-screw foundation

Before proceeding with the description of the insulation technology, I will tell you why in general this procedure Needless. Of course, the insulation of the foundation will make warmer and gender, however, you can perform insulation of the floor in the house on the piles, without touching the foundation. Hence the question arises - is it worth doing this at all?

In fact, insulation needs to be performed for other reasons:

- under the house, as a rule, communications are held. The insulation of the foundation will protect them from freezing in winter. True, it is additionally necessary to fulfill the insulation of the communications themselves;

- insulation implies the arrangement of the base, thanks to which the house acquires a more solid and attractive appearance;

- the presence of the base prevents the accumulation of snow and water under the house, which is also very important.

As you can see, the insulation of the foundation is a really useful procedure, which is advisable immediately after the construction of the house.

Warming technology

So, the process of insulation of the foundation consists of five main stages:

Step 1: Selector Selection

Before proceeding with the insulation of the foundation, it is necessary to prepare all materials. In particular, you need to decide with the insulation. For designated goals suitable next species Thermal insulation materials:

- extruded expanded polystyrene - is a modified foam, which is characterized by higher strength and durability, so it is often used for the insulation of the caps. On average, the price of extruded polystyrene is 4500 rubles per m3;

- polyurethan - applied to the surface in the form of foam with the help of special equipment, after which it quickly freezes. The advantage of this insulation is that it forms a solid coating on the surface, without cold bridges. However, keep in mind that it will not work with your own heat insulation. The cost of insulation along with the work begins from 350-400 rubles per square meter;

- thermopanels are combining insulation and finishing material. The cost of the panels is an average of 1000 rubles per square meter.

On our portal you can read more details with the features and characteristics of these insulation.

In addition to the heat insulation you will need boards and bars for mounting the crate. In addition, finishing material should be prepared. It may be:

- siding;

- base panels;

- aceid, etc.

If you are insulated with thermopanels, the finishing material, of course, will not be required.

Step 2: Performance

Many masters perform a breakfast after the insulation of the foundation, however, it is advisable to start work from the breakfast. In this case, the insulation of the base will lay down to the insulation of the scene, and not to the freezing soil.

The scene is performed as follows:

- around the perimeter at home, dig a trench of a width of about a meter and a depth of about 40 centimeters;

- now float the bottom of the trench by sand, the layer thickness should be about 20 cm. The sand should be carefully tumped;

- then it should be filled with a layer of rubble with a thickness of about 5 cm, after which it is thoroughly smugging and tamped;

- next, you need to put on the rubbish waterproofing film. The canvas should be laid a mustache;

- now the insulation material should be placed on the waterproofing, for example, extruded polystyrene foams are excellent for these purposes;

- at the outer edge of the scene, the drainage tube should be laid, as shown in the diagram above.

On this work on the breakfast ceases until the insulation of the foundation is performed.

If the foundation warming is performed outside on bunny soils, on the joint section of the base and the gentlestation, the trench should be covered with a clay. Due to this, in the event of a soil, the base is not worried.

Step 3: Installation of crates

Before heating the pile foundation wooden houseIt is necessary to fulfill the crate to which not only the insulation is fixed, but also the finishing material. The frame usually consists of two three bunches of boards, which are mounted around the perimeter of the base.

The boards are most often attached to the extreme pile. If the piles are metal, they can be welded horizontal planks and drill holes. As a result, the board will not be difficult to fix bolts.

If you do not want to get involved with welding, you can consolidate the crate with the help of a clamp. Another option is to attach the crate to the walls of the house. To give the stiffness design, the vertical jumpers can be positioned between the boards, which can be fixed with screws.

Step 4: Warming

The process of insulation depends largely on the type of heat insulator. Therefore, we consider it all possible options insulation:

| Type of heat insulator | FEATURES OF MONTAGE |

| You can attach to the crate with the help of dowels-umbrellas. At the same time, to eliminate the bridges of the cold, all the joints of the insulation with the wall, as well as with each other, be sure to fill in the mounting foam. It should be noted that the insulation is better to mount from the inside, in this case there will be no problems in the process of cladding the base. |

|

| Polyurene Foolder | As mentioned above, this insulation is simply sprayed on a warmed surface. Therefore, when installing the crates, place the boards as close as possible to each other. You can also be insulated from the inside after the cladding of the base. |

| Thermophali. | This material is attached to the crate with the help of dowels or special fasteners, which are included. |

If the house uses a wooden scarlet, before heating the foundation, it must be treated with a protective impregnation. In addition, all other wooden elements, including the crate, are processed by this composition.

After mounting the insulation, you should pour the device with concrete. After that, work is stopped for a while until the concrete is free.

Step 5: Facing

The final stage is the cladding of the base. Most often for this, the basement is used. The instruction on its installation looks like this:

- on the perimeter of the house, the starting profile is attached from below to the crate. It must be located strictly vertically, so it is necessary to install it using a construction level;

- next panels, the bottom of the bottom is rented in the starting profile, and the top - attach to the bracket by self-drawing;

- at the end of the work, it is mounted for good elements - salts, corners, etc.

Performing cladding cladding, you need to foresee for ventilation of the underground space.

A more complex facing option is a brickwork. In this case, the perimeter of the structure is made finely brewed ribbon foundationon which the wall of the base is erected.

I must say that fine-breeding foundation You can pour on your own, find out in detail how you can do on our portal. But the laying is better to entrust to those skilled in the art, since cladding requires high qualification of the mason.

Another option is to shelter the Azeid base. The panels can be mounted for trint of nails. In the future, the ACEID is covered with cement plaster.

The finish finish of the Aceaide is performed at personal discretion, for example, it can be separated by artificial or natural stone, tiles or other material.

Here, in fact, all the main nuances of the insulation of the pile foundation.

Floor insulation

To achieve maximum effect from the insulation of the foundation, you must also warm the floor. So finally, I will tell you how this procedure is performed:

- first of all, it is necessary to wall a draft floor. You can make it in two ways - to rinse sheets or other sheets from below to lags or from the bottom on the lags to fasten the rails (draft bars) and lay sheets on them, as shown in the scheme above;

- then, the waterproofing film of the Vansel is stacked on the lags and draft floor. For greater tightness of the joints should be skilled with scotch;

- next, the waterproofing is placed on the waterproofing. It is best to use mineral mats for these purposes. It should be noted that the insulation must fit tightly to the lags so that the cold bridges remain;

- then, on top of the insulation, another layer of thermal insulation is stacked.

Now on top of the lag you can put the boards or other flooring. Thanks to all these manipulations, the floor in your home will remain warm even in the cold season.

Output

The process of insulation of the pile-screw foundation as a whole is quite simple. It is only necessary to correctly mount the crate and then consolidate heat insulation on it, taking into account all the above recommendations. In addition, be sure to heat the floor to ensure the most comfortable living conditions and reduce energy consumption for heating.

Additional information contains video in this article. If, after reading the material, you will have questions about the insulation of the foundation, ask them in the comments, and I will gladly answer you.

September 6, 2016.If you want to express your gratitude, add clarification or objection to ask the author - add a comment or tell me thanks!

With any variations of climatic conditions, the pile-screw type of foundation is the most universal of all existing at the moment. It's kind of metal designwhich consists of separate elements related to the strapping and welding.

Houses on such foundations are erected on any soils, regardless of their freezing, the availability of water in the ground and bunchiness. Constructive features Distribute the load on the lower layers, which have greater strength and are not susceptible to the harmful effects of soil water.

The only but significant minus arises due to the design features. A large unlocked space under the house is the cause of a cold floor that causes discomfort during operation.

Method of elimination of minus pile foundation

The process of cold gender is solved by the insulation of the foundation in various ways.

The type of insulation is selected depending on the height of the foundation above the ground.

Features of the design and the fact that the "bottom" space will be used for economic purposes.

Several options should be considered:

- full insulation;

- outdoor;

- floor insulation under the house with an external side.

Full

In this case, work is carried out on the insulation of the entire design, both outside and from the inside:

Outdoor

This method is suitable at a low house location when the magnitude of the piles is small, and implies the organization of the frame around the perimeter, ranging from the line of the earth's surface to the edge of the building. It is then possible ornamental cladding and insulation.

Floor insulation Outside

If the house is significantly raised relative to the Earth and other options are impossible, the so-called "partial insulation" is performed - from the external, lower part of the building.

Despite the fact that from the point of view of professionals, the ventilated part is better to leave open, many owners of houses on the pile-screw foundation prefer it to be covered and insulated with various available funds.

Waterproofing device

If you do not fulfill all activities on the competent device of waterproofing, the metal from which all elements of the design are made may be corrosion. Wooden elements can be affected by fungi and refuse.

If you do not fulfill all activities on the competent device of waterproofing, the metal from which all elements of the design are made may be corrosion. Wooden elements can be affected by fungi and refuse.

The loss of piles or wood features are able to significantly affect the service life and the leading of the building.

In order to protect the structure, one of the waterproofing materials is placed on the place of contact of the pile elements and painters. For example, it may be a rubberoid layer. It should also be placed on the tops of the woodwork, which are joined with a wall of the building.

Following this, the whole foundation is treated with waterproofing mastic, and wooden parts are an antiseptic.

After a week, after finally absorb solutions, the following stage is performed - the insulation of the foundation.

Two ways of insulation of the base part of the structure

- brick wall laying;

- preparation of frame for decorative trim panels.

Brickwork

For a start, a small trench rotates and a shallow foundation is formed: reinforced and poured. Actually, he is already an additional insulation. Then, after graze, it is laid out a small wall of the brick of the required height. Masonry is performed half of the brick.

Installing frame for panels

The guides are welded on the pile design for fasteners of panels, which are then glued or screwed. The kennels of the panels are covered in the corners, and are mounted.

The guides are welded on the pile design for fasteners of panels, which are then glued or screwed. The kennels of the panels are covered in the corners, and are mounted.

Regardless of the selected insulation material, it is recommended to perform ventilation holes that must be made diagonally diagonally. In order to avoid the penetration of rats, go other rodents, each of the holes is necessarily closed with a grid.

This type of ventilation will not give humidity within this space.

Insulation expanded polystyrene

High density polystyrene (extruded) has good insulating and sound insulation properties and makes it possible to produce high-quality insulation of the foundation on screw piles.

In addition, a sheet of material in an inch with a quarter almost does not reduce the inner volume of the base.

Phased performance

- Before mounting the heaters of the insulation, a brick or concrete wall must be prepared: clean from dirt and dust, eliminate irregularities and cracks and treat primer (preferably deep penetration, GGP).

- Installation of polystyrene sheets is performed using special adhesive compositions or montage foam. Warming elements are fixed using special mounting dowels.

- The space between the ends of the sheets must be insulated (mounting foam, mineral wool, etc.). To achieve the best thermal insulation properties, sheets are attached in two layers.

- Metal grid is fixed over the insulation to protect against rodents.

- Along the inner perimeter of the base (along the walls), a clay is made of a claying.

Mineral wool insulation

This is a heat insulating material with good characteristics, non-combustible and non-toxic.

Phased performance:

- If the Martex has high density, it can be fixed on the base of the mounting dowels.

- Waterproofing from rolled materials (rubberoid, tol, linocur, etc.)

Floor insulation

When applying a screw pile foundation, it is necessary to provide the manufacture of floors together with thermal insulation. In the case of its absence, it is necessary to produce thermal insulation outside the building.

Phased performance:

- Installed a layer of vaporizolation.

- The layer of the selected insulation is fixed (according to the temperature regime).

- The next is a waterproofing layer of rolled materials.

- The resulting design should be protected from mechanical damage to an additional layer. Materials can serve as boards or sheet materials (plywood, CSP and other).

At the end of work at the same time, not only insulated floor, but also prepared ceiling of the economic basement is obtained.

The insulation of the pile-screw foundation will solve the issue of cold floors, will reduce energy consumption associated with heating and will extend the life of the whole house.

Preface. In this article, we will analyze such a question as the insulation of the foundation on the screw piles. This type of foundation is increasingly gaining popularity due to its simplicity and lack of need for earthworks. But its use makes you think about how to insulate the space between the house and the soil, which material to use and how to properly insulate the foundation using screw piles.

Do I need to warm the foundation on the screw piles?

The feature of the foundations mounted on screw piles, in the unclosed gap between the foundation and the soil on the site - in this place there should be a warmed base of the house, in connection with this, work on the protection of such a design from cold is characterized by certain difficulties. Increasingly, when construction on bubbly soils and high groundwater levels, foundations mounted on screw piles are used as the most durable structures that protect the house from dampness.

Warming of the foundation from screw piles brick masonry

The foundation with screw pile represents the design of the piles of beweded into the soil, which are support for the beams, to which the entire load of the walls of the house lies. The most efficient use of the pile foundation in the construction of houses from a tree, so a timber is most often used for paintwork, although metal beams can also be applied. Is it worth insulating the foundation from screw piles? To answer the question, you should consider the design device more details. Next, we will look at how to build a house from a bar on screw piles do it yourself. Video from the "Excellent House" program will help in this matter.

Foundation device using screw piles

Piles consist of a metal pipe with a diameter of 100 to 300 mm and up to 9000 mm long. The wall thickness can be from 8 to 12 mm. The piles are ending with blades, with the help of which they drill the soil and are supporting the pipe. On the other Pipe tube has "Hats", which are used to set the scratches (jumpers).

Before mounting the piles, it is necessary to explore the soil, which runs on the site, is undesirable to the presence of solid rocks in the ground, interfering with the vertical screwing of the piles. It is necessary to take into account the load on the screw foundation of the walls of the house to calculate their quantity. The depth of piles depends on the depth of the fruit of the soil, the possible height of the flood water and the depth of groundwater. It also affects the choice of insulation.

When twisting piles, leave a 14-20 cm reserve above the ground level, and then adjust the level under the stacking of the scum (jumpers) using levels. Piles after twisting and alignment should be filled with a solution, which will increase them and reliability when the soils and loads from the walls. Then, with the help of welding or bolts on piles, the headings are mounted, after that, the mounting and fastening of the writs (beams) connecting piles around the perimeter is made.

How to insulate the foundation on the screw piles

In any house, the main condition for a comfortable microclimate is a warm floor. The main negative feature of the foundation is the presence of space under the floor, which leads to the receipt of the cold from the bottom. Given the raising of warm air upwards, it is necessary to insulate the foundation of the house, high-quality insulation of the basement to protect the house from the tributary of cold air through insufficiently insulated floors and the base.

Warming foundation from piles Minvata

Since the insulation (for example, mineral wool) will contact the soil, then the insulation should be chosen for the foundation using screw piles, which is not afraid of moisture, and in which rodents will not start. There is also a need to create a design (frame), replacing the missing base of the house and its subsequent insulation of minvata or penplex. Therefore, work is made outside and from the inside.

If you choose mineral wool, it should be carefully protected from moisture with a layer of waterproofing. When using inexpensive foam, the insulation should be additionally protected from rodents. With the insulation of the foundation from the screw piles (the pile of the screw foundation) of the penplex additional work Not needed, because the polyurex is not afraid of moisture, it will not settle rodents in it, as well as it is much stronger than foam.

How to insulate the foundation on the screw piles do it yourself

The insulation process can be divided into steps:

Waterproofing design - piles and woodwork.

Making a frame that replaces the base of the house.

Installation on the "socket" of the insulation, the proportion of the joints.

Fastening the decorative finish panels on the "base".

The root of the inside of the soil or clay.

1. Waterproofing design

Regardless of whether the framework of a bar or metal is made, waterproofing of all joints is necessary, through which dampness can penetrate, leading to mold, rotting of the tree or metal corrosion. In addition, given the independent insulation of the screw foundation, it is necessary to protect all open parts of the structure with rolled and liquid waterproofing. Wooden elements should be treated with antiseptic impregnation, protecting from mold and insects.

To create a heat saving facing, it is necessary to create an imitation of the base of the house. The design can be made of a light brick wall, which will need to be insulated outside the foam layer and close with decorative panels. You can use a timber or metal guides to create a frame.

2. Production of "socle" at home

In the first case, between pile, it is necessary to dug a trench at 15-20 cm, pour the reinforced foundation. After full frost, lay out the light wall of the red brick. The subsequent insulation of the foundation on the screw piles outside is carried out on this brick wall. Guides are attached to the brick, between which the insulation is stacked. On the finished wall, it is necessary to fix the decorative panels imitating brick or stone masonry - Very beautiful material.

The second method is to fasten the horizontal bars to piles with bolts or metal horizontal guides using welding. Further, how to insulate the pileno-screw foundation with their own hands of a wooden house will not cause special difficulties. It follows between the guides to lay foam, or foam plates, and joints to be treated with mounting foam. Next, it is waterproofing the insulation and the installation of decorative panels outside.

3. Installation of insulation

When the roof is insulated with a minvata or another rolled insulation, the distance to 1 centimeter is less than the width of the insulation, so that the minvat is tightly pressed to the guides, and did not produce. Also mineral wool should be carefully closed with vapor barrier from moisture and dampness.

When insulating the foam of the foundation on the screw piles or use of the foam, the seams should be perfect. If the Penoplex does not absorb moisture and is not afraid of rodents, the foam should be carefully closed with waterproofing and take care that the mice cannot build a house in the insulation.

Decorative panels on the base of the house

Uninstall the insulation can be vinyl or metal siding. To do this, it is necessary to attach the starting profile on the perimeter at home. And then from him to go up, attaching the siding stripes. Recently, decorative PVC panels are popular in the form of brickwork or wild stone.

Decorative panels and siding will remove the insulation from moisture, rodents and mechanical damage. And in order to additionally insulate the foundation from the screw piles in winter, then you can throw on the Snow Cocol. With a high-quality finish of the base, the insulation will not burst and will not suffer, and the snow will additionally save heat into a tall frost.

5. powder soil or clay

From the inside, the warmed foundation from the screw piles can be added soil or clamzite, which will reduce the injection of underground space. Mandatory in opposite sides of the base should be equipped with ventilation holes closed with lattices from rodents and insects. Ventilation serves to ventilate and remove moisture from the home of the house, the ventilation grilles should be closed for winter.

Warming of the foundation on screw piles. Video instruction