Calculation of the volume of the solution for brickwork. Calculation of the amount of cement and sand for brickwork. How many cubes in a bag of dry cement or construction mixture

Each builder before proceeding to the construction of a building, thinks about how much the necessary materials should be purchased to avoid the fact that after the end of construction, it will remain cement or brick reserves. To do this, it is necessary to clearly calculate the amount of all materials that will be involved in the construction site.

In our article we will focus on how to determine the consumption of the solution on the brick laying.

Right calculations

To correctly fulfill all the calculations, you will need a roulette and computing skills. When performing calculations, it should be determined which type of work will be performed, because the qualitative characteristics of the solution depend on it. Solutions can be: concrete, slag cement, sandy-cement, and others. The strength of these solutions will depend on the grade of cement and quantitative composition. For example, for a concrete screed, when filling the floors, the M200 brand concrete is most often used, for the preparation of a solution for brick or slag cloth masonry, a mixture with hardness from M50 to M100 should be used. To prepare a mixture from which the slag blocks themselves will be molded, a solution with a brand hardness can also be used from M50 to M100. For plastering walls, a solution with hardness M50 to M100 should be taken. After you have determined with what concrete solutions you will work, you can proceed to calculate what cement, what brand you will need to purchase.

Sand-cement mixture

For the manufacture of a sandy cement mixture, you should purchase cement with a hardness brand, which will be higher in 2 or 3 times than the hardness of the finished solution. So, if you need to prepare a solution with a hardness M100, you must purchase cement with M200 or M300 brand. If you are going to cast concrete blocks, the cement hardness brand should exceed 6 or 8 times the brand of the future concrete solution.

After we all sowed all these questions, you can already start directly to the calculation of the consumption of the solution itself. To perform a floor screed or filling the foundation to find the desired volume of the solution, you must multiply the length of the width, and then to the height of the alleged layer of concrete. To calculate the amount of solution for brickwork, it is necessary to proceed from the fact that 0.25 cubic meters of solution will be approached for each square meter of masonry. For laying concrete blocks, consumption will be significantly less, about 0.05 cubic meters per square meter. The most consumed grade of cement is the M400 brand, as it can be prepared solutions with the most different brand of hardness using this brand, using only different percentages.

Table relations

Now we give some table ratios, clearly showing the solution consumption for brickwork. For masonry of one cubic meter of a brick wall thickness in one brick you will need 0.221 cubic meters of solution, for masonry as a thickness of 2 bricks, you need 0.24 cubic meters of solution. Solutions for masonry bricks are three types: a three-component solution consisting of cement, water and sand, cement-lime solution, a solution with the addition of plasticizers. Regardless of what solution for masonry bricks you will stop. The voluminous characteristics of the finished solution will be the same, detailed consumption can be viewed in the following table,

Comments:

In order not to have the problem of the lack of material, it is necessary to know the consumption of cement on the brickwork. Indeed, it uses the composition based on cement binder to fix the elements of structures. Such a means must be prepared in place before starting work.

Brickwork is made on cement mortar, which must be carefully calculated before starting work.

Calculation is important for cement, it is also important because it cannot be purchased with a reserve, since the excess material will quickly lose their properties under the influence of moisture and air. If it is possible to properly determine the consumption of cement on the brickwork, it will optimize the cost of construction (taking into account that the cost of building materials has a noticeable effect on the final calculation).

Factors defining the need for substance

Cement mortar for brick masonry must be calculated in advance, because the residues quickly lose their properties under the influence of moisture.

The consumption of cement on the brick laying depends on the two main parameters: the structure of the mixture and its need for construction. The masonry may have a different cement content depending on the designation of the structure (carrier, internal system, etc.) and resistance requirements to the affecting factors. In this connection, two main types are distinguished: cement-sand and cement-lime-sand mixture having different proportions of ingredients.

The weight of the solution during masonry depends on the structure of the structure and the type of brick element itself. A direct dependence of the need is observed from the thickness of the wall, which is customary to express in the amount of bricks laid in a row. The most common thickness is 0.5, 1, 1.5 and 2 bricks.

The volume of the solution to fasten the elements depends on the material from which the brick is made and its type (monolithic or hollow). The seam size and, as a result, the means of means are determined by the composition of the brick bar (normal, red or silicate) and its dimensions (standard, modulated).

Back to the category

Composition of cement mixture

When erecting a brick design, the grade solutions from M50 to M150 are used, depending on the requirements for the strength of the system. The most commonly private construction uses a simple two-component composition - cement with sand, and a brand of M75 is enough. In this case, the proportions of cement and sand make up 1: 3 (with the use of Portland cement M300). For other brands, the following ratio is adopted:

- M50 - 1: 5;

- M100 - 1: 2;

- M150 - 1: 1.5.

M100 and above compositions with a large binder content are needed for high-strength systems (structures).

Consumption of the cement component can be reduced by introducing a more durable portland cement M400 and above. So, when using the M400 brand, you can take the proportion of 1: 4.

The question of how to calculate the amount of portland cement in the mixture at different concentrations is solved very simply. For example, with the ratio of ingredients 1: 3, the volume of the cement component is ¼ of the total volume of the solution, i.e. 0.25 m³ per 1 m³ of mixture. With an average density of the material of 1600 kg / m³, the need for cement on 1 m³ of solution reaches 400 kg (8 standard bags of 50 kg). Accordingly, for Portland cement M400, the volume will be 1/5 part, or 320 kg / m³.

To accurately calculate the weight of the cement, it is necessary to take into account the width of the seams, the degree of alignment of each layer and other unmarried nyuans.

Experienced builders prefer to use a more plastic composition of cement, lime and sand in a ratio of 1: 1: 3 (M75 M75 M75) or 1: 1: 4 (with portland cement M400). For internal partitions, a composition corresponding to the M50 brand is used, with a proportion of 1: 0.5: 4.5 (Portland cement M400).

Estimation of the required cement weight is made similar to the previous case. With a ratio of 1: 1: 3, the M300 cement is 1/5 of the volume of the mixture, or 320 kg / m³. Portland cement M400 is added in an amount of 1/6 of the total volume, which is about 0.17 m³, i.e. 272 kg. When erecting brick partitions on inappropriate lightweight structures (for example, economic buildings), cement savings are achieved by a decrease in its concentration to the proportion of 1: 5 or 1: 6.

Back to the category

Masonry

If you calculate the accurate weight of cement on brickwork in each particular case, then we must take into account the real width of the seams, the variation of the geometry of the element, the degree of alignment of each layer of laying and other process parameters. This calculation is very complex, and the refined volume will differ only a few kilograms from the standard estimated counting, which has no significant value. In this regard, it is customary to use generalized data on the cost of the solution on the construction of a segment of the wall of a single volume. These data obtained on the basis of many years of construction work.

In practice, it is customary to take into account the dependence of the consumption of the solution from the wall thickness and size of the brick itself. The details are given reference values \u200b\u200bof the consumption of cement-sand or cement-lime-sand composition per 1 m³ of brick masonry for the usual and thickened (modulated) element with different wall thicknesses.

| Name of works | Materials | unit of measurement | Consumption rate with wall thickness, bricks / cm | |||

| 1/25 | 1,5/38 | 2/51 | 2,5/64 | |||

| Per 1 m³ | ||||||

| Laying the walls of the brick of an ordinary or silicate single full-scale | Brick | pC | 400 | 395 | 394 | 392 |

| Solution | m³. | 0,221 | 0,234 | 0,24 | 0,245 | |

| Laying of walls from an ordinary or silicate single hollow | Brick | pC | 400 | 395 | 394 | 392 |

| Solution | m³. | 0,223 | 0,236 | 0,242 | 0,247 | |

| Laying of walls from ordinary or silicate modular | Brick | pC | 300 | 296 | 294 | 292 |

| Solution | m³. | 0,205 | 0,216 | 0,222 | 0,227 | |

| Laying of the walls of external clay ordinary or silicate single full-scale with an average design | Brick | pC | 402 | 400 | 398 | |

| Solution | m³. | 0,237 | 0,241 | 0,245 | ||

| The same, from the brick of a clay ordinary or silicate single hollow with the middle design | Brick | pC | 402 | 400 | 398 | |

| Solution | m³. | 0,239 | 0,243 | 0,247 | ||

In the manufacture of a brick structure, an extended seam is sometimes used. The following are data on the need for mixture for such laying.

| Name of works | Materials | unit of measurement | Consumption rate when using brick | |||

| single full-time | single hollow | modular | ||||

| on 1 m³ masonry | ||||||

| Brick masonry of external walls with a thickness of 55 cm with simple architectural design | Brick | pC | 369 | 369 | 278 | |

| Solution | m³. | 0,28 | 0,293 | 0,273 | ||

| Masonry of external walls with a thickness of 55 cm with medium architectural design | Brick | pC | 373 | 373 | 281 | |

| Solution | m³. | 0,274 | 0,277 | 0,263 | ||

When planning the construction of brick walls, it is necessary to pre-calculate the number of building materials and the cement consumption for brickwork - it allows you to save significant funds. Being a hygroscopic, cement powder over time loses its physical properties, so do not buy it with a large margin. Interim calculation of the volume of the solution

We are necessary for its rational use during the work shift or to perform a certain amount of masonry.

Varieties of solutions and their use

The link between brick blocks is a mixture of the binder component with filler and water. The most common 4 types of solutions are the most common.

- Cement-sandy. It is divorced by water, its proportions depend on the cement brand, the masonry method. When frozen, this option is most durable, but during the retreat from the technology is inclined to the formation of cracks;

- Lime - in it cement is replaced by a negro lime; plastic, but washed with rains, so it is only suitable for mounting inner walls;

- Mixed - cement and sand are diluted with liquid haired lime (lime milk). The combination combines the best qualities of the first two options;

- With a plasticizer - to cement and sand (fraction 2 mm), a polymer additive is mixed to increase the plasticity of the mixture. It is easier to make this solution from a dry building mixture by adding water according to the manufacturer's instructions.

Despite the composition, the quality requirements of the mixture are almost the same. All ingredients are cleaned from lumps, sand is sifted, liquid lime is filled. For the preparation of the solution, the powder components are first thoroughly mixed, then the cold liquid (20 o C) is slowly poured and stirred thoroughly so that there is no grapplation. The process is accelerated using a concrete mixer or a perforator with a nozzle in the form of a whisk.

Despite the composition, the quality requirements of the mixture are almost the same. All ingredients are cleaned from lumps, sand is sifted, liquid lime is filled. For the preparation of the solution, the powder components are first thoroughly mixed, then the cold liquid (20 o C) is slowly poured and stirred thoroughly so that there is no grapplation. The process is accelerated using a concrete mixer or a perforator with a nozzle in the form of a whisk.

Solution consumption for brick masonry cube

How much to prepare a solution for laying the wall? This is determined by several conditions:

- mastery of the Mason;

- the structure of the brick unit - products with voids take more of the mortar mixture;

- brick type - hyper pressed and facial silicate less absorbs solution than ceramic or ordinary silicate with a rough surface;

- wall thickness.

The average solution consumption per 1 m3 brick masonry with a standard seam thickness (12 mm) is about 0.23 m3. More accurate information gives Table 1.

Table 1

| Name of works | Brick type | Regulatory consumption (m3) with wall thickness, bricks | |||

|---|---|---|---|---|---|

| 0,5 | 1 | 1,5 | 2 | ||

| Outdoor and interior walls, simple design | 0,221 | 0,234 | 0,24 | 0,245 | |

| Hollow | 0,223 | 0,236 | 0,242 | 0,247 | |

| Modular | 0,205 | 0,216 | 0,222 | 0,227 | |

| Medium architectural decoration | Ceramic ordinary, silicate single full-length | 0,237 | 0,241 | 0,24 | 0,245 |

Cement consumption for brickwork

The composition of the mixture for the construction of a brick wall varies depending on the quality of the source components, weather conditions, the floors of the building. To properly mix ingredients, you should know: the 10-liter bucket contains 14 kg of cement or 12 kg of sand.

Cement consumption on brickwork when cladding

In this case, the developer is interested in how much astringent mixture is spent on a square meter of the wall. It depends on the water absorption of the building material, the season of performance of work, voidness and porosity of blocks. The norms are laid in SNIP 82-02-95, but the real numbers are always greater, so you should buy a ready solution or a reserve cement.

In this case, the developer is interested in how much astringent mixture is spent on a square meter of the wall. It depends on the water absorption of the building material, the season of performance of work, voidness and porosity of blocks. The norms are laid in SNIP 82-02-95, but the real numbers are always greater, so you should buy a ready solution or a reserve cement.

To save on consumables, 2 factors should be noted:

- the more brick dimensions, the less the solution will take;

- the higher the% emptiness and pores, the mixture consumption will be higher.

From this point of view, the optimal is the use of ceramic or silicate double bricks of a sufficient stamp of strength. Such a choice will make it possible to achieve a 20% solution of the mortar mixture. Table 2 shows comparative data consumption per square meter of the wall.

Cement consumption per 1 m2 of masonry is considered based on its proportional content. If the mixture is composed of calculation1: 3, then the square meter of the wall with a thickness of 380 mm from the full-scale brick is needed: 0.095 x 490 \u003d 47 kg of cement.

Cement consumption per 1 m2 of masonry is considered based on its proportional content. If the mixture is composed of calculation1: 3, then the square meter of the wall with a thickness of 380 mm from the full-scale brick is needed: 0.095 x 490 \u003d 47 kg of cement.

Proper compilation of the solution and the choice of optimal dimensions of the stone allows for the brickwork to withstand the consumption of cement in the regulatory limits.

For years, decades and even the century are replaced, and the brick has been and remains the most popular building material. It is environmentally friendly, distinguished by durability and good thermal insulation properties. But the quality of the future wall depends not only from it, but also from the solution. It must be comfortable for stacked, well fill in the seams, have a good coupling with bricks, to be resistant against precipitation. His strength depends on how correctly it is defined on brickwork. The masonry of the walls of the brick is allowed to produce only for cement mortar.

In order, after time, the brickwork layout did not like and did not go cracks, it is important to pay attention to the quality of the solution.

Depending on the designation of structures and the alleged load, different brands of a binder solution with a cement content of certain brands are used.

When laying bricks, it is necessary to ensure that the solution fills all empties in the masonry.

In some cases, the use of a lime-cement solution is allowed to build internal partitions, in which the flow rate of the binder decreases. To increase the plasticity in the masonry mixture, various additives are introduced. Do not be surprised, but sometimes even ordinary shampoo add there!

Preparation of masonry mixture provides for the use of sand, cement and water. The ratio of the first two components usually takes 4: 1. This means that for the preparation of 1 m3; A binding solution It is necessary to use the fifth part of the cement. Based on the fact that weight is 1 m3; This material is approximately equal to 1300 kg, the consumption for the preparation of the solution will be 260 kg.

Determination of cement content

It should be remembered that the solution for laying quite quickly begins to fit, so it is not necessary to prepare it.

The necessary calculations are easiest to perform by taking the laying of 1 m3;, consisting of 400 bricks. On average, it is necessary to 0.25-0.3 cube solutions to its laying. Knowing it, you can produce simple exemplary calculations and determine the required consumption of the binder per 1 m2; Walls of any thickness.

Calculations are made in such a sequence:

- calculate the area of \u200b\u200bthe wall, multiplying its length to the width;

- determine the estimated volume of paperwork, multiplying the wall area on its thickness. It should be noted that the construction of bearing structures is usually performed in 1.5 or 2 bricks. Their thickness will be 38 or 51 cm, respectively. Internal partitions are made in 1 or 0.5 bricks, which will be 25 or 12.5 cm. For example, we give the calculation to build a wall laid out in 1.5 bricks whose area is 12 m2: 0.38 x 12 \u003d 4.56 m3;

- the calculated amount of the mixture for this scope of work: 4.56 x 0, 25 \u003d 1.14 m3; It should be borne in mind that the approximate need may vary both in large and in a smaller side depending on the material used and the master's experience. Therefore, the calculated amount is quite approximate.

- knowing the mandatory ratio of components, we determine the necessary need for cement: 1,14: 5 \u003d 0.23 m3;

- since the weight of 1 m3 of cement is 1300 kg, then in this case it will be necessary: \u200b\u200b0.23 x 1300 \u003d 296 kg.

The weight of one bag of cement is about 50 kg. This means that to build the wall, taken for example, it is necessary to use 5 bags. Similarly, it is possible to determine the estimated binder consumption for any brick design.

The building calculator is designed to calculate the proportions and composition of cement-sand and cement-ceraimsitic solutions, selection of the necessary mobility and calculating cost.

Construction - a sphere in which it is impossible to do without cement mortar. The strength of the solution depends on which brand of cement you will be applied, from the sand size module and comply with the rules of hardening. The mortar must be used no later than 30 minutes after the manufacture.

The method of cooking a mortar.

Sand and cement on dry mix in the necessary proportions, and gradually poured with water, until the desired mobility is obtained. If necessary, the calculated number of plasticizers initially breed in water. In order to avoid sticking the solution on the walls of the concrete mixer, the water must be poured into a mixture with small portions.

The required grade of the solution depends on the brand of materials used. For example, when brickwork with a brick brand M100, it is necessary to mix the solution of the same brand. For the preparation of a solution under the base of the foundation, a solution of less strength can be used than the storage of the foundation. To calculate the necessary brand and mobility, use the Calculator of the selection of the composition and proportions of the building solution.

For more comfortable work with cement solutions, plasticizers need to be applied or for household work ordinary detergents. They help to achieve the plasticity of the solution and simplify the mixing process. The selection of plasticizers is large enough, it is necessary to choose the most suitable for your conditions, for example, in cold times you need to use plasticizers with anti-corrosive additives.

For brickwork and building blocks there are "warm" solutions, with the addition of heat-saving binders, such as polystyrene foam, clay and perlite sand. Such solutions prevent the heat loss through the "cold bridges" and make the wall more monolithic in their properties.

An important parameter is the mobility of the solution. It is necessary to pick up the one that corresponds to the type of work. Approximate table of mobility of construction solutions:

- masonry of stones by vibration

- ordinary laying of boob stones; Installation of walls and extending seams in the walls of large panels and blocks

- laying of hollow and full-scale bricks, building blocks; Pouring emptiness

- Plastering

There are 3 types of solutions differing in composition.

- Lime solutions

- Cement-lime solution

- Cement-sandy

- The strength of them is less than the pure cement mortar, however, they are warmer and has a large plasticity. For the manufacture uses lime dough, ground smooth lime and sand.

- It includes cement and limestone dough. It is very plastic and has high strength, can be applied almost for any kind of masonry.

- It is based on cement and sand. Such a mixture without plasticizers is quite rigid, as well as a low-lifting.

General information on the results of calculations

- Number of cement

- Number of water

- Number of aggregates

- Density of solution

- Proportions

- Cost

- The total estimated amount of the required cement on the entire solution.

- The total calculated amount of water required for the entire volume. Attention! The final amount of water is selected by an experimental way, depending on the humidity of the sand.

- Total amount of sand (aggregate) for the entire volume in kilograms.

- The density of the solution in the raw state.

- Water-cement ratio.

- relative ratio of the components of the solution. C - part of cement; P - part of the sand; In - part of the water.

- The cost of each material and total for the entire volume.

stroy-calc.ru.

Initial data

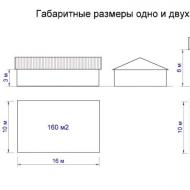

Initial data for calculating bricks in an online calculator and their description:

- It is necessary to specify the width, length and height of the structure along the outside. In the event that the height of the walls is different, you must enter the average value. Example: if 2 walls with a height of 7 meters, and the other two 5, then (7 + 7 + 5 + 5) / 4 \u003d 6;

- Select brick size for construction from the list of proposed or enter your dimensions. When choosing bricks from the list, the "Brick Weight" parameter is inserted automatically. When you enter your sizes and the need to calculate the "Load for Foundation from the walls" parameter, you need to introduce brick weight;

- It is necessary to choose the thickness of the wall from the proposed options (without facing and finishing materials). If the facing brick is calculated, the wall thickness is 0.5 bricks.

The wall thickness affects the carrying ability, which should ensure the structure of the necessary resistance, as well as to withstand the weight of overlaps and roofs, taking into account the loads acting on them.

Depending on the climatic zone in which construction is produced, there are standards for the optimal thickness of the wall, depending on the thermal insulation. It is possible to build thicker walls from bricks, but it is not economically appropriate. Among professional builders there is an opinion that the optimal thickness of the wall of 1.5 bricks. Brick durable material, and this thickness is enough to create the necessary bearing capacity. If necessary, further enhance the design or improve heat-insulating characteristics expediently and cost-effective materials; - The thickness of the masonry solution is chosen dependent on the brick geometry and the type of brick masonry. The thickness of the solution is 10 mm most common. The thickness of the seams should be the same. The seams should be completely filled with a solution without forming voids;

- The masonry mesh in brickwork is used to increase the strength of carrier structures. The reinforcing grid is usually placed every 5 rows of masonry;

- For a more accurate calculation, you must specify the number of fronts (the frontton is the completion of the facade, which is limited to the roofs of the roof on the sides and the eaves at its base), doors and windows, as well as their size. In the case of different sizes, enter them in the total area in the respective graphs (the area can be calculated in this calculator and fold them).

Result of the calculation

Description of the results of a brick calculation in an online calculator:

- The perimeter of the enclosing structures is the sum of the lengths of all enclosing structures, measurement units - meters;

- The walls of the walls - the area of \u200b\u200bthe external sides of the enclosing structures, excluding the frontones / doors / windows, units of measurement - square meters;

- The total area of \u200b\u200bthe frontoths is the area of \u200b\u200bthe masonry on the frontows, which is summed up with the laying area on the wall;

- The total area of \u200b\u200bthe windows is the area of \u200b\u200ball windows that is deducted from the walls of the walls, the units of measurement - square meters;

- The total area of \u200b\u200bthe doors is the total area of \u200b\u200bdoors, which is subtracted from the walls of the walls, units of measure - square meters;

- The total area of \u200b\u200bthe walls of the outside of the external sides of the enclosing structures, taking into account the frontones, doors and windows, units of measure - Square meters;

- The total number of bricks is the amount of bricks needed to build the structure of the specified parameters, units of measurement - pieces;

- The total weight of the brick is the weight of the whole brick required to build the structure according to the specified parameters, the units of measurement - kilograms. Useful parameter when calculating delivery;

- The total volume of bricks is the volume of bricks required for construction, dubic meters measurement units. Useful parameter when calculating delivery;

- The total amount of solution is the total amount of solution required to build the structure of the specified parameters, units of measure - Cubic meters;

- The total weight of the solution is the estimated weight of the solution required for masonry at the specified parameters. The weight may differ, depending on the volume weight of the components and their ratio in the solution, the units of measure - kilograms;

- The total weight is the estimated weight of the finished walls, taking into account bricks, a solution and a masonry grid, units of measure - kilograms;

- The wall thickness is the thickness of the finished wall, taking into account the seams, the units of measurement are millimeters;

- The number of rows, taking into account the seams, the number of rows is shown without taking into account the frontones, depends on the overall dimensions of the selected brick and the thickness of the solution in the masonry, the units of measurement - pieces;

- The amount of mosquito net is the total amount of mosquito net used to strengthen the design erected, meter measurement units;

- The optimal height of the walls is the height of the walls, excluding the frontones, which is obtained when laying from brick, selected size and thickness of the solution in the masonry, units of measurement - meters;

- Load for foundation from walls - This parameter is necessary to select the foundation. It is shown without taking into account the weight of overlaps and roofs.

stroyFora.ru.

How to make the calculator masonry calculator?

The brick is the most popular and common building material, serves a long time and pleases the neat appearance. To date, there are several types of bricks for the construction of buildings:

- brick of clay and other fillers, called saman;

- ceramic, most used, from burnt clay;

- silicate, made of sand and lime;

- with the addition of cement - hyper pressed;

- clinker, from a special composition;

- refractory.

Such materials are used both for masonry at home and for the construction of additional finishes in the future, creating a facade, interior structures. Chamotte brick can carry high temperatures, as well as various heating and cooling cycles without loss of strength.

Bricks can be hollow, porous, the most common standard size of this product is 250 × 120 × 65 mm, with preliminary calculations of the resulting brickwork, the brick sizes are increased by 10 mm of each parameter.

What data do you get when filling out the form of an online brick calculator in the masonry?

- The total length of all walls of the structure around the perimeter of the structure.

- The total area of \u200b\u200bmasonry outside the walls.

- The wall thickness will be taken into account based on the thickness of the finished wall and the size of the dissolve seam.

- The total number of bricks and the total weight of the material.

- The amount of solution on all masonry will depend on the ratio of components and the added additives.

- And the length of flexible links will be determined by the overall thickness of the wall, taking into account the number of insulating base.

- The amount of masonry grid will improve the overall strength of the structure.

- The approximate weight of the finished walls will be calculated without taking into account the weight of insulating materials and cladding.

To make the calculator calculating the calculator - online, you need to enter the required parameters in the preparative table and click on the "Calculate" button. After a few seconds, the program will give the maximum accurate result. The percentage of error may vary from 3 to 7%.

How to make the calculation of the amount of masonry solution?

To make a solution for brick masonry, you need to mix sand and cement to create a plastic mixture, usually such a ratio of materials is equal to a third of the sand and one cement.

But the final consumption will be determined by the special requirements according to the laying material and the grade of the raw materials used. Often, additional additives (clinker, marble, crushed stone, synthetic substances) are added to the finished mixture, in order to increase the masonry setting speed and increase the strength of the material.

Calculation of the amount of solution for brickwork can be done using an online calculator, which for counting seconds as accurately defines the amount of solution on brickwork.

Types of brick svs

Types of brick svs The solution consumption depends on the type of selected seams.

Such a program will allow calculations relative to the total cement mixture. The accuracy of the data obtained will be determined by the accuracy of the indication of the size of the wall and seams.

In the presence of concrete bees of the walls, it is planned to calculate from the height of common measurements. Construction calculator Flow Calculator for 1 m 2 brick masonry makes it possible to quickly and conveniently make the calculation of the desired parameters.

Types and sizes of bricks for masonry

Types and sizes of bricks for masonry Such data will allow you to navigate the value of masonry, as well as make the calculation of the required amount of construction. Depending on the additional additives, rigidity, strength, mobility and grappiness of concrete will depend on

Calculator Flow Calculator on Brick Masonry will help to avoid unnecessary material costs, if you correctly calculate the flow and other works, for example, the fill of the foundation, wall screed, etc.

sdelalremont.ru.

Consumption of a masonry solution for masonry of brick walls

1. Enter the area of \u200b\u200bthe wall in the m2 elevated.

2. Select the wall thickness in bricks or sortimeters.

An example on the laying of a wall of 15 m2 thickness in 1 brick will need:

1715 pcs. Brick I.

0.0272 m3 solution

How to calculate the composition of the solution for masonry yourself? If you decide to build a garage with your own hands, or a small country house, then you, if you are not a professional builder, you will need to know how to prepare a solution for masonry, what kind of components you need, and what it should be. To solve this problem, the masonry solution calculator will help you.

The calculator will make you a calculation for both ordinary and facing bricks and for different types of blocks, both for manual kneading and concrete mixing. It's easy enough to use it.

You first need to decide what kind of masonry will be. The masonry can be allowed, with vibration, or without it, from full-length brick, blocks, and a lot more. After you have decided on the type of laying, you put it in the calculator.

Then you need to know which brand and mobility of the solution for this type of masonry you will need. This data you also put in the calculator. Now you need to roughly calculate the amount of solution that you go to the laying. Then you decide whether to make a solution manually, or use the concrete mixer. The volume of concrete mixers is also important, so we choose it and enter the data in the calculator. When determined the volume of concrete mixers and brought data into a calculator, we need to know what brand cement you will use. Its amount in solution depends on the cement mark, the higher the brand, the less it is necessary for the desired solution.

After we brought all the data to the calculator, click the Calculate button, and we obtain the result. At the outlet, we must obtain both the composition of the solution on 1 m3 of the mixture, with the number of components, both in kilograms and in liters, for more convenient operation. We also obtain the composition for each individual kneading, based on the volume of concrete mixer, or the tank used for the preparation of the solution and the number of damps for the volume we need.

Thus, the calculator of the masonry solution is available to everyone and is quite simple to use.

terramall.ru.

Question. Hello! I plan to purchase cement for the preparation of a solution for masonry of walls by ordinary brick. Tell me how much you need to buy cement for brickwork? It is meant by 1 m3 of masonry and for masonry 1,000 pcs. Brick. Also interesting, there is a difference in the amount of cement for masonry ordinary and facing bricks?

Answer. Good day! To answer the questions set, some simple mathematical calculations should be made and take some assumptions. Initially, we consider the issue of masonry design by ordinary brick and asked the following source data:

- Dimensions of ordinary brick: 250x120x65 mm (0.25x0.12x0.065 m).

- The volume of ordinary brick in M3: 0.25x0,12. 0.065 \u003d 0.00195 m3.

- Masonry masonry mark: M150 or M200.

- Cement brand for preparing a solution: CEM I 32.5N PC and CEM I 42.5N PC (old designation M400 and M500).

To determine the required amount of cement of different brands per 1 m3 of the masonry of ordinary brick and 1,000 pieces of ordinary bricks produce the following calculations. We determine the amount of masonry solution in m3 per 1 m3 of masonry:

- Quantity of bricks in 1 m3: 1 / 0.00195 \u003d 512.8 pcs. We accept 513 pcs.

- The number of bricks in 1 m3, taking into account the masonry seams: 394 pcs. (empirical data).

- The amount of masonry solution on masonry in m3: 513-394x0,00195 (volume of 1 brick) \u003d 0.232 m3 solution.

We determine the amount of cement CEM I 32.5N PC and CEM I 42.5N PC per 1 m3 masonry with M150 and M200 solutions and reduced it to the table.

The following formula was used when calculating: The table consumption of cement per 1 m3 solution was taken for 100%. Estimated cement consumption per 1 m3 of masonry (0.232 m3). Consistently (depending on the grade of the cement and grade) multiplying the table consumption of cement by 1 m3 solution to the calculated consumption of cement per 1 m3 of the masonry received the consumption of binding per m3 masonry in kilograms.

Determine the number of cement on laying 1,000 pcs. Private brick. Knowing the amount of cement (different grades for a solution of different stamps) on the laying of 394 bricks determine the amount per 1 piece, then 1000 pieces and we reduce into the table.

| Mark solution | Brand cement | Consumption of cement on laying 1 pc. Brick, kg. | Cement consumption for laying 1000 pcs. Brick, kg. |

| M150 | CEM I 32.5N PC | 93/394=0,236 | 236 |

| CEM I 42.5N PC | 80/394=0,203 | 203 | |

| M200 | CEM I 32.5N PC | 111/394=0,281 | 281 |

| CEM I 42.5N PC | 96/394=0,243 | 243 |

We return to the question of the consumption of cement on the masonry by ordinary brick and masonry ceramic facing brick. The dimensions of the ordinary facing brick correspond to the dimensions of the ordinary "masonry" brick, so there is no difference in the amount of cement for the preparation of a masonry solution.

Summing up, it should be noted that in practice the calculated values \u200b\u200bobtained may differ slightly both in the large and smaller way. A subjective factor comes into force - the skill and conscientiousness of the Bricklayer builder.

cementim.ru.

Factors affecting the calculation of the flow rate of 1m3 brickwork

The most important factor affecting the flow is the form of a solution used for masonry. There are four types:

- Cement-sandy. This mixture is made of water, cement, sand. With proper application, this solution is very durable and stays long, not crackging.

- The limestone mixture is a solution in which the negated lime acts in the role of cement. Such a mixture is not suitable for external work, as it is quickly damaged by moisture.

- Mixed. With proper preparation, this solution will combine all the advantages of the two previous solutions, minimizing the disadvantages.

- A mixture with a plasticizer. A special polymer additive is added to the first solution to increase its plastic properties.

For the manufacture of cement-sand solutions, the grade of the strength of cement 2-3 times should be higher than the strength of the finished mixture (for example, for the M100 strength solution you need to buy the M200 or M300 cement).

Organic and inorganic additives are often added to concrete to improve its properties, mobility, stiffness.

In addition to the type of solution, the consumption of solution on the masonry of the brick depends on the materials, sizes and properties of the brick itself. The thicker the wall, the more expense will be. If the brick is not full, and the hollow, the mixtures also spend more.

Consumption per cubic meter

There are standards that determined the solution consumption for 1m3 masonry. For full-scale brick with standard sizes (250x120x65) requires the following volume of the consumption of the solution of the brick masonry:

- for half (120 × 120 × 65) will be 0.189 m3;

- for single (250 × 120 × 65), there will be 0.221 m3;

- for one-time (380 × 120 × 65) will be 0.234 m3;

- for dual (510 × 120 × 65) will be 0.240 m3;

- for dual and a half (640 × 120 × 65) will be 0.245 m3.

Thus, one full-length brick requires about 0.0006305 m3 solution. Therefore, on 1 m2 brick masonry width 120 mm, about 75 liters of the mixture will be required.

For modulated bricks (250x120x88), the consumption will be somewhat less:

- for half (120x120x88) there will be 0.160 m³;

- for single (250x120x88) will be 0.20 m3;

- for one-hour (380x120x88) there will be 0.216 m3;

- for dual (510x120x88) there will be 0.222 m3;

- for double and a half (640x120x88) will be 0.227 m3.

For hollow bricks, 1M2 masonry solutions will be more.

Cement consumption

After calculating the desired amount of the mixture, it remained to find out how much and what brand should be purchased cement. It is always better to buy cement "with a stock" - in case of an unforeseen expense or great error in the calculations.

If 20.0 m3 of the mixture is required, and the proportion of the solution is 1: 3, then the obtained value must be divided by 4. It will be 5.0 m3 of cement. However, cement is not measured in cubic meters, you will have to translate it into a kilogram. To do this, you need a hardener density, which in different brands can be very different. On average, the value is approximately 1300 kg / m3. Taking into account the knowledge of this indicator, uncomplicated calculations remained: multiply the density to the volume. Thus, it turns out 5.0 * 1300 \u003d 6500 kg, or about 130 bags, when taking into account that the weight of each bag is 50 kg.

Brick consumption

For construction, it is necessary to find out not only the consumption of the solution on brickwork, but how many bricks will be required. Depending on the size, the indicator of how many bricks in 1m3 will change greatly. The calculation results will also be obtained by others, if we take into account the dissolves.

On 1 cubic meter will need:

- 512 single bricks excluding dissolve seams (394, taking into account);

- 378 (302) one-hour;

- 242 (200) double.

On 1 m2 thickness of 120 mm will be required:

- 61 bricks are single excluding dissolves (51, taking into account);

- 45 (39) one-time;

- 30 (26) double.

1 m2 250 mm thickness will be required:

- 128 single bricks excluding mortar seams (102, taking into account);

- 95 (78) one-time;

- 60 (52) double.

On 1 m² of 380 mm thick, it will be necessary:

- 189 single bricks excluding mortar seams (153 taking into account);

- 140 (117) one-time;

- 90 (78) double.

When laying, it is important to take into account the size of the brick, and you need to not forget its properties (on the hollow bricks of the masonry solution will be required more than full-scale), as well as the nature of the work performed. For internal works, a solution with haired lime instead of cement may be suitable.

In construction, you need to know how much solution for masonry brick will be used, and how much the keys will be required.

With proper and accurate calculations of the consumption of bricks and the solution, there should be no problems with the construction. Just in case of all materials it is worth making more than 5-10% to eliminate unexpected situations.

In addition to cement and brick, you can also calculate the consumption of all kinds of additives, but for this you need to accurately know the parameters of the manufactured mixture.

You can also watch a video about the calculation of bricks and a solution:

kirpichguru.ru.

Masonry solutions calculator