Bavarian laying smooth. Brick "Bavarian Masonry": Features of use and review of manufacturers. Brother Bavarian Masonry: Production Features and Benefits

Bavaria is famous not only by the largest brewery, but also in unique architecture represented by castles and town halls. On its lands lived whole generations of masonry and it was here that new trends in the area of \u200b\u200bbrickwork were born.

The concept of "Bavarian Masonry" has its own historical justification. During the growing popularity of the brick, the Master faced with such a problem as the heterogeneity of the color of the material from different parties (and the party then were very small).

As a result, in order to avoid ugly stains of different shades, the Bavarian craftsmen came up with the original output - uniformly mixing of different bricks (on tone darker or on the tone lighter) during the masonry process to get a motley background.

Only at first glance it may seem that bricks are posted in chaotic order, in fact, in such a laying, a certain rhythm has always been settled with a predetermined alternation of colors and the ratio of light and dark shades. You can not allow the concentration of one color (such spots will spoil all the cladding), exactly, as well as a strict geometrical pattern.

Features of the modern "Bavarian Masonry"

Today, in private construction, the popularity of the Bavarian Masonry is gaining popularity and a special brick is already used as a facing material, buying which you immediately receive several colors in the party in an equal ratio. Experts have already taken care of the combination of shades and proportionate. Depending on the preferences, you can choose a combination of different shades of one color, or a combination of contrasting colors. In any case, such a cladding will become exclusive.

In the modern market there are not only classic collections consisting of 4 colors, but also two-color and multicolor (up to 8 colors and shades). You can experiment both with coloring bricks and with the color of the masonry solution. At the same time, the same set will "play" in different ways with light or with dark seams.

Some of the leading places in Russia for the production of such bricks occupy Braer, Slavic, Golitsyn and Starokolsky (Brand Recke).

Brick Plant Braer (Tula region)

It is the largest brick manufacturer that meets world quality standards. Products are available on modern European equipment and has no analogues on the Russian market. The company controls all stages of production: raw materials production, design development, introduction of innovative technologies (there is its own research laboratory), quality check and the implementation of its product.

Braer produces facing ceramic bricks of all formats from 0.7 NF (euro) to 1.4 NF (one-hour), but the most optimal size for Bavarian Masonry is 1 NF (single standard). Hollow bricks have high strength (M150), excellent frost resistance (F100) and water absorption less than 10%.

The full range of Facing Brick Brick is represented by the largest dealer specializing in building materials - buscus companies .

Here at the most favorable prices and with the best delivery conditions you can buy the following colors of Brick Brick:

format 0.7 NF.

- oak bark with sand (there are small splashes);

- oak bark;

- smooth (classic red color with a change of tones);

- mocha smooth (original gray color).

format 1 NF.

- reef (has a corrugated surface);

- terra (surface is not smooth, but with shallow depressions);

- oak bark;

- oak bark with sand;

- mocha smooth;

- bordeaux smooth (4 shades of burgundy);

- smooth (brown coloring with halftones).

format 1.4 NF.

- smooth (classic).

Retail price per unit of products for 2017 is from 20 to 30 rubles (1 sq. M. meter will cost, respectively, in 1000-1500 rubles), which is lower than the average market.

Slavic Brick Plant (Krasnodar Territory)

The plant is equipped with modern German equipment with high performance. Production is carried out using plastic formation technology. Collections of facade ceramic bricks are distinguished by the unique style and new color solutions that give the building a presentable view and bright personality.

Hollow brick is represented only in standard 1 NF format. In the manufacturing technology, the Angoda method is used (applying to the surface of a thin layer of white or colored clay with additives and dyes), which increases decorativeness and reduced water absorption up to 8%. In addition, Slavic facing brick is characterized by increased strength (M200).

The bruscon catalog contains the following interesting collections: Provence (shades of blue), Hamburg (gray), Gothic and Milan.

- Provence is smooth with Angurization (unusual blue-purple color);

- Provence Rust (Surface "Rustic" with shallow wrinkles, less bright compared to Provence Color);

- Provence Bunt Antique (gradient red-blue color, the surface "Rustic" with sand);

- Provence Antique (differs from the previous species only uniform blue color);

- Provence Bunt Rust (distinguished gradient painting bricks with a transition from red to blue);

- Hamburg Rust (has a gray background and the surface "Rustic");

- Hamburg Bunt (gradient coloring with the transition from dark gray to the jaco brown, the surface is smooth);

- Hamburg Bunt Rust;

- Gothic antique (the surface "Rustic" with sand);

- Gothic smooth (bright combination of contrasting colors);

- Milan with Angry (each brick is unevenly painted in several colors, a smooth surface);

- Milan with an Angry gray-brown (smooth surface).

Brick SCZ Provence Antique Rust with sand on the object under construction

The retail price of the manufacturer's product does not exceed 20 rubles / pcs, which makes the products are very attractive, especially for the facing of the private house.

Golitsyn Ceramic Plant (Moscow region)

He has a century of development history and a rich experience of brick production. Production lines are constantly upgraded, which allows you to produce high-quality building materials in accordance with European standards. The company produces a huge range of products that differ in the method of coloring (including two-color), surface type and sizes, including non-standard solutions. Facing brick has strength from M175 and frost resistance F100, water absorption does not exceed 9%.

The plant produces 5 collections of single brick: Bavaria, Country, Old Prague (light milky-gray), Milan (dark terracotta), Venice (relief surface).

The company Brusus offers the most popular options:

- Country smooth two-color;

- Old Prague two-color;

- Milan smooth two-color;

- Bavaria Reef two-color;

- Wenge is smooth.

The price for one brick is 20-25 rubles.

Staroscolsky Brick Plant (Brand Recke Brickerei)

Focused on the production of an Alforded premium class brick. To withstand product quality at a high level allows equipping modern expensive equipment and active introduction of innovative technologies. A distinctive feature of Recke products is a special color feed: there are warm tones carrying in the distant past, and glossy metallic overflows from the technological future.

The facing brick Recke has the strength of M200 or M250 and water absorption of less than 6%.

Brick Catalog "Bavarian Masonry" on the site Bruski is submitted by the hollow decorative brick format 1 NF of the following types:

- red-brown;

- gray-beige-brown;

- yellow-brown (2 options);

- brown-yellow.

All material has a smooth surface that can be glossy or matte. The price for such a brick is 39 rubles, which is quite natural.

Bavarian masonry (it. Bairisch - Bavarian) - type of decorative masonry, in which the brick of different colors is laid out in a chaotic order, creating a unique picture. It is known from the XVII century and appeared on the territory of Germany. In those days, it was rather difficult to get a large batch of the same brick, and the bricklayers found a way out of the situation, creating harmonious combinations from different colors. Subsequently, this type of laying has grown into an independent direction and acquired its modern appearance.

Application area

- Finishing walls of houses;

- Landscape design;

- Fireplaces;

- Finishing internal interiors;

- Pools;

Our online store offers you a facing brick Bavarian laying, as in recent years it is becoming increasingly popular among developers. Plants manufacturers offer a wide range of color palette and shades of products that can satisfy the most refined taste of the customer. In the classic design of the brick, the Bavarian laying has four main colors - brown, red, dark red and black and brown. In modern versions, the company offer not only basic colors, but also a large number of shades. For example, Bordeaux, oak bark, oak bark with sand, terracotta, straw.

Features of performance

To create a high-quality drawing, which will delight the eyes for many years, it is desirable to follow several laying rules.

- Before starting work, make a pattern - several sketches of the future pattern made on paper. Combining various patterns, you will get a unique combination of patterns;

- Try all the tile elements to be black. You can post a few "twitch" in a row, and then continue laying with spoonful;

- To obtain the effect of "chaotic" laying, take the material not from one pallet, and from all alternately;

- The proportions of dark and bright areas are kept in the same proportion, without the predominance of dark or bright areas;

Since we work directly with the manufacturer, you will definitely please our price for a facing brick Bavarian Masonry producing TM Braer. Store consultant online will help you determine the required amount and color gamut material. We also provide the delivery of your order to Pokoche and the Moscow region.

In the past century, due to the imperfection of the firing process, the finished products were acquired by different shades, as a result of which the surface of the houses looked heterogeneously. Nowadays, the motley brick walls turned into a fashion trend, and such facing of the facades began to be called Bavarian Masonry, since its homeland is the Southern Land of Germany - Bavaria. German bricklayers learned to combine blocks from different parties, creating unique "outfits".

According to scientific terminology, a differential ceramic unit is called "Flash brick of reduced roasting". To achieve the effect of heterogeneous color, at the factory during thermal processing periodically turn off the air supply to the furnace. At such moments, oxygen is extracted from clay to maintain combustion, and the temperature on the surface decreases.

At the last stage, the power of the air flow is increasing, due to which the sheath of the billets is strongly heated, producing a molecule of certain connections from clay and changing its color. Control of processing modes allows you to plan shades in advance. With high temperature firing, properties are improved:

- increases strength and resistance to external loads;

- the surface sinters and becomes solid, like glass, does not destroy under the influence of external factors;

- frost resistance is 75-100 cycles;

- water absorption stabilizes: for conventional ceramic it varies in the range of 6-14%, and for flash bricks - 6.8-9.5% (if there is emptiness - up to 7.5%);

- the thermal conductivity of hollow options is reduced to 0.19 W / m o C (ceramic - 0.44 W / m o C);

- almost no supremes - salts have time to decompose during the firing process.

"Motley" brick compared to glazed (painted) more environmentally friendly. Flash technology retains "breathable" quality. The only disadvantage of modernized ceramics is a high price, quite explaining the complexity of technology. Multicolored blocks are also used for the outer row of the bearing wall, the manufacture of architectural elements under load.

Specificity Bavarian Masonch

So that the house is original, it is enough to combine from 3 to 5 shades of the facing. The greater the color options, the hardest work. The scheme can be calculated using special computer programs. According to the results of the calculation, it remains to purchase material in the desired proportions at the factory or in the trading network. Professional bricklayers use their techniques:

- Bricks take not from one pallet, but from different - for example, from five.

- The main tone is determined (its share is at least 50%), complement it with auxiliary in an arbitrary ratio.

- A few patterns of rectangular sections containing the desired color ratio of colors are written on Watman's sheet. Making 5-10 fragments, combine them in various combinations and are looking for the best "random" pattern.

- The wall is drawn up only under the extection, it looks more spectacular with the use of colored solution.

- A private house looks peculiar, if such a masonry apply only for the design of door and window openings, arched arches, columns. Such an approach allows not only to purchase the desired amount, but also to save.

- Original cottage with a common motley background and monochrome corners.

In the classic version, preference is given to brown and red tones. Modern designer ideas are based on a more diverse palette. The cottage is originally with alternating blue, gray and light yellow flowers. If you wish, you can buy smooth or flat facing brick.

Brick manufacturers review and assortment

Domestic enterprises that have mastered progressive technologies equipped with modern equipment and automated lines, produce quite decent products suitable for Bavarian masonry.

1. Brier brick factory.

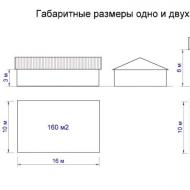

The main enterprise of the BRAER group is a production complex located in the Tula region and has its own deposit of Suglinkov (Obdimsky). The product catalog includes a selection of standard sizes - 0.7 NF (euro, 250x85x65), 1NF (single, 250x120x65); 1,4 NF (one-hour, 250x120x65 mm).

Not only smooth, but textured models are available: reef (with long straight grooves), oak bark (with asymmetric short furrows). Recently, new items have appeared in the assortment - oak bark and corrugated sand. On their surface, white decorative sand was sprayed, thanks to which the masonry flashes under the sunlight, as if it was covered with an end.

The varnotonic facade material is traditionally represented in a rich color scheme:

- mocha (gray-brown);

- terra (red-brown);

- bordeaux;

- red;

- straw.

2. Fifth element.

The company is located in the Kaliningrad region. For technical equipment and production volumes, the company is one of the leaders among domestic manufacturers of wall building materials, and product quality is responsible for the new GOST 530-212 and the European regulatory document EN 771-1: 2011.

- Full-time. It is produced in one standard size - 1NF (single), has increased strength (M300), a density of 1900-2000 kg / m3. Allocated blocks are used for exterior walls, columns, chimneys, fireplaces.

- Hollow with thickened wall. In this category, 3 types are produced: euro, single and one-time. Thanks to a fairly high class of strength (from M175 to M200), they can be used both in the role of facing and for masonry of bearing walls. It is an effective heat insulator: thermal conductivity coefficient does not exceed 0.193 W / m * o C.

Due to the improved technology, the color palette is expanded to 20 shades. The assortment has smooth and rousified (relief) options. Private houses laid out of rustic or canyon (collection are distinguished by the depth and frequency of notes) very expressively.

3. Magma Brick Plant.

This is a relatively new enterprise located in the Republic of Mordovia. For the manufacture of products, the automated line of Keller (Germany) is served. According to the technology of reduced firing, the hollow block of the following types is released:

- single smooth;

- one-hour smooth;

- single antique - killed, straw shade, with light rifer;

- single maple is gray-brown, with deep, chaotic grooves.

According to the strength of the flash product correspond to the M150 brand, the density is 1200 kg / m3, water absorption does not exceed 8%. The thermal conductivity is somewhat higher than that of the fifth element - an average of 0.39 W / m m * o C. Decent decorative qualities: no openings, proper geometry. To buy magma is advised for facing the above-ground part of the fences: the masonry is obtained sufficiently dense, the water absorption is low.

Cost and characteristics

Prices from manufacturers on the main types of reduced roasting bricks.

| Manufacturer | Characteristics | Price, rub / pcs |

| Brother | Single, slit, corrugated with sand, M150 | 22 |

| Single, slit, oak bark, M150 | 29 | |

| Single, slit, corrugated, M150 | 19 | |

| Euro, slit, smooth, M150 | 16 | |

| One-hour, slit, smooth M150 | 28 | |

| The fifth Element | Full, single, smooth | 41 |

| Hollow, single, smooth | 28 | |

| Hollow, single, rustic | 25 | |

| Single smooth | 20 | |

| Magma | One-hour smooth | 27 |

| Single antique | 21 | |

| Single Maple | 21 |

Facing the walls in this way arose in Germany in the 17th century. What is now applied as an element of decor and to make a variety in the interior, the German pasta of the past was a forced measure. Due to the imperfection of the production technology, bricks were obtained different in color shades, the building lacked the same building material for building construction.

It was accounted for from what was, had to mix bricks from different parties. To make the end result beautifully looked, the bricklayers were selected suitable bricks and created beautiful combinations of them. But now we can take advantage of such an interesting option for wall cladding, allowing not only to decorate, but also to strengthen the facade or fence.

Where applies the Bavarian masonry

Using Bavarian Masonry:

- facing of outdoor walls of buildings;

- facing internal interiors: fireplaces, furnaces;

- bavarian masonry can be an element of interior design. Brick is laid out one of the walls, for example, in the hallway, or in the kitchen, or in another indoor room at home or apartment, depending on the design of the interior solution;

- facing fences, arbors, decorative tracks, pools and other buildings.

In the Bavarian masonry there can be up to 8 combinations of colors and shades of bricks. The classic is considered a combination of red, brown and darker shades of these colors, in total in the traditional version of 4 colors.

For cladding, a smooth brick is used, and embossed. In one building, it is possible to combine material and the other surface, but do not mix them, but to highlight the separate bricks of the individual elements of the structure, and the main facing is relief, or vice versa. Possible bavarian laying options can be found on the Internet. Creation Rules Bavarian Masonry:

- the first row should include bricks of all colors;

- the number of bricks of all colors should be approximately the same;

- try evenly distribute dark and light colors so that there is no effect "spots";

- before starting work, it is better to consider the variants of the drawing (patterns), up to 10-12 pieces, which are then used for decorative wall cladding;

- when selecting flowers, it is necessary to keep in mind that the combination of contrasting bricks can produce an unforeseen effect, so you need to be careful in choosing a colors of the cladding;

- there should be no symmetry in the figure, when looking at the lined structure, the impression of chaotic repetition of colors should be created.

Views of Bavarian Masonch

Application options Bavarian brickwork in the photo:

In the Bavarian brickwork, you can use a combination of monotonous masonry and color. In one color, for example, the corners of the house are highlighted, window and doorways are folded. In the facing of individual elements, the laying of a Christmas tree is also used if the master owns such a technique.

Interesting will be a combination of bavarian masonry and two-color. In this case, the corners, platbands, the doorways are made by light, and the walls themselves are red shades, and one, and others are performed by Bavarian masonry. In this case, close color shades are used (photo).

How to choose a color gamut for bavarian brick masonry

Designers recommend first to choose the main color, then the second color is selected to it, or a contrast to the first or close in color. It depends on your taste preferences. They are selected the necessary number of other shades close to the color scheme to the first selected.

Choosing the color of bricks, think over exactly what color seams will be in the masonry, because the color of the seams also strongly affects the appearance of the future building.

For your information ! On the sites of manufacturers of facial bricks for Bavarian masonry, you can choose a color gamut of materials, and at the same time pick up the color of the suture solution. Working out the design of your future home, do not forget that the wall cladding should be harmoniously combined with the color and material of the roof.

When planning to use Bavarian masonry in the house facing, consider that the picture should not be repeated. The distribution of colors should create the impression of chaoticness, but that the end result is impressive, this chaotic is thoroughly thought out.

Methods of Bavarian Masonch

Bavarian masonry can usually be done in two ways.

- arbitrary drawing, which is obtained when alternating bricks from all pallets;

- performing chaotic combination thanks to pre-thought-out patterns.

In the first version, the first row should include bricks of all colors, then monitor the neighboring bricks to be one color, and the vertical seams should match the row.

Important ! To avoid one-photon spots on the facade, the laying must be made from all pallets at the same time.

In the second embodiment, the Bavarian clock laying scheme is thought out in advance, billets of sketches are made, so-called patterns, in an amount up to 10-12 pieces. They can be drawn independently, or using a computer program. Patterns are rectangular sketches of combinations of bricks, given the requirements of Bavarian masonry, that is chaotic, lack of repetitions. Then the patterns are also repeated in any order. This option is more complicated, requires skills, patience, more costly in time, but the result will be much more effectively.

The last design fiction was the combination of light combinations in which one dark shade was added to the same color and one contrast. As an example, you can cite a combination of gray shades and the addition of blue bricks, or a combination of blue with straw-yellow shades.

Advantages of Bavarian Masonry:

- gives your design decorativeness, make a built house in unique, unlike the rest;

- the wall cladding increases the sound and thermal insulation of the building;

- brick facing is resistant to ignition.

Features of decorative wall cladding

Facing can be performed simultaneously with the erection of bearing walls or after the end of the main construction work.

There should be 3-4 cm of the airbag between the facing and bearing wall, which can be filled with thermal insulating material. The decorative wall must be fixed to the carrier with special spiral nails, or lay galvanized punched punctuent, which you need to nail to the carrier wall.

In the Bavarian masonry for fixing with the inner walls, the taches are also used, which are performed through 4-5 spoon rows. Another embodiment of the decorative and carrier wall can be the alternation of tiles in each spoonful row. For this, facing and ordinary bricks must be of the same size.

In order not to create a greenhouse effect, it is necessary to leave the vent holes during decorative laying. To do this, 3-4 row of bricks are placed without using the solution. This will allow air to circulate and increase the life of your home.

Choosing materials for decorative facing

Now the brick plants produced products specifically for cladding Bavarian Masonry. One of the factories specializing in the production of such products is Brier's brick factory located in the Tula region. He proven himself as one of the leading manufacturers of facing bricks for Bavarian laying. At your request, you can choose from the proposed samples color, as well as the surface of facing bricks, which are manufactured by the plant in two versions: smooth and relief.

Professional bricklayers love to use Brier Brier in Bavarian masonry, provided good quality material. By purchasing facing material, refer to proven suppliers to not be a victim of unscrupulous dealers. If you are new to construction before determined with the choice of cladding for the house under construction, check the photo brief brief photo for Bavarian Masonry. Perhaps the ratio of price and quality of the goods offered will be quite an acceptable choice.

The purpose of the outdoor cladding of the house is to create a solid and aesthetically attractive shell of a house that protects the responsible structural elements from the effects of atmospheric precipitation, mechanical damage, etc.

In this regard, the facing brick is one of the most reliable materials performing all the necessary functions.

Facing has the usual view of the brickwork, natural for the walls of the construction, but the quality of the material is much higher than in the ordinary brick, which allows you to create a durable and beautiful outer layer that cuts off the outer moisture and additionally insulated walls.

The durability and reliability of facing bricks make it use attractive to users who value the stylish appearance and the foundation of the material.

The Russian company Brother produces several types of facing ceramic bricks. High quality products is explained by constant quality control, using modern equipment and improving technological methods of production.

Brother's company aims to produce products with best worldwarm and does not regret the efforts spent on achieving success. The abundance of facing materials has not reduced the demand of facial bricks, as the most durable and reliable material.

Ceramic facing brick has high strength. The hollow structure of the block makes it possible to eliminate the accumulation of stresses in the firing, which reduces the possibility of cracking or destruction.

Smooth shape, accurate geometric lines make a possible high-quality masonry, creating a neat and stylish decorative lining. The front side of the brick can have a smooth or textured surface that creates the effect of a rough or perfectly smooth wall.

The facial brick has several color options, as close as possible to the natural color of the burned ceramics. One or more colors, creating a certain geometric pattern or the so-called Bavarian masonry, when the wall consists of several brick colors, chaotically and evenly located all over the area.

There are 5 linewood material:

- Red.

- Muscat.

- Brown.

- Bordeaux.

- Bavarian masonry.

Brick Brother is considered one of the best facing materials manufactured in Russia and fully meet all European standards of quality.

Dignity and disadvantages of material

Brother facing brick has the following advantages.:

- High strength.

- Heat-saving properties caused by the presence of cavities inside the block.

- High decorative qualities.

- Environmentally friendly material.

- Low ability to absorb water.

- Good tolerability of temperature drops.

- High resistance to mechanical stress, shocks, scratches, etc..

- The durability of the material is capable of competing with the service life of the house.

- The relatively low weight of the material that does not create additional load on the foundation.

- The cost of cladding brick, given the durability and the lack of need to be selected and repair the facade, much lower than any other external finish method.

The disadvantages of facing brick include:

- The complexity of laying. A qualitatively folded facade requires the involvement of qualified specialists with appropriate skills and experience. Independent cladding is possible only in the presence of preparation.

- Facing work is made using wet compositions, which complicates the possibility of finishing the finished house.

Specifications

Facial brother's brick has the following parameters:

- Format - 0,7NF, 1NF, 1,4NF.

- Length - 240 mm.

- Width 120 or 85 mm (0.7NF).

- Height - 65 mm or 88 mm (1,4NF).

- Weight - 1.7, 2.3, 3.1 kg.

- Brand - 150-175 kgf / cm2.

- Frost resistance - at least 100 cycles.

- Water absorption - 8-9%.

- Number in the pallet - 600 pcs.

Production technology

The production chain of production begins in a career where clay is mined, which is the main raw material. Production workshops are located 1 km from the career, which greatly simplifies logistics, and also reduces the cost of production.

Clay is mixed with water, special additives that give products additional properties and creating texture. After that, the brick is molded and sent to the firing.

Flashing technology is called Flashing. Its essence is to limit the amount of oxygen under the firing of ceramics, allowing to receive different shades of color without using dyes. When burning under the conditions of the oxygen deficit, many carbon arises, which, burning, gives shades of black products.

Brother's firing furnace has a length of 240 m, being one of the longest in Europe. Extensive facilities of the material of the material - the basis of high quality and specific properties of facial brick.

Production quality control is carried out by its own laboratory equipped with modern equipment. It allows you to conduct constant quality monitoring, timely detect technological deviations or regulate the production process.

Bavarian masonry

Bavarian laying is the use of several brick colors on the same plane. Previously, when the brick is firing, it was impossible to achieve the same color for all blocks, so the masters tried to evenly distribute the bricks along the entire surface with a darker or bright shade.

The wall was varied, but such an appearance turned out to be quite attractive aesthetically. The imperfection of technology, which in the old days was trying in every possible way to avoid, today is a sign of style and is widely used in the outer decoration of houses, buildings, fences. Miscellaneous methods of creating Bavarian masonry are used - using from 2 to 7 colors.

Brother's company produces a special brick grade - Bavarian laying having the following varieties:

- Corrugated with sand.

- Smooth.

- Bark oak with sand.

- Mocha.

- Terra.

- Bordeaux.

NOTE!

All varieties have several colors of color, allowing to create a "rowan" effect of varying degrees. At the same time, the result obtained largely depends on the mastery of a mason producing masonry. The same set of bricks can be distributed in different ways, which may look natural to one degree or another.

Basic Rules for creating Bavarian Masonry:

- Do not lay two bricks with the same color.

- Before starting work, carefully sort the material, after which it is possible to mix it as much as possible by shades.

- Methodically distribute the available colors on the plane, while avoiding accurate repetition of the alternation of shades.

Rules are simple, but requiring some skills and experience in drawing up. Sometimes the darkest (or light) bricks are stacked at the corners, emphasizing and additionally decorating them, making the design of the walls more ordered.

Preparation of walls to facing

Before starting work, you should make sure that the foundation is reliable and its ability to withstand an additional load from facing bricks. This moment is especially important for two-storey (or more) houses that receive a significant increase in the mass of the walls..

The second important point will be the determination of the sufficiency of the place for the support of brick on the foundation. If the insulation is planned about 5 cm thick, plus 3 cm of the ventilation gap and plus 8 cm brick width (the minimum support area should be at least 2/3 of the brick width), then the presence of a foundation band is at least 16 cm wide.

If this ratio is not maintained, the width of the base band should be increasing with steel corners attached to the foundation by anchors. It is also necessary to check the magnitude of the eaves, which, if necessary, be increasing. The protruding masonry will pick up moisture in emptiness, will be broken during freezing, so this question should be responsibly solved.

Preparatory work includes:

- Actually surface preparation.

- Installing insulation with waterproofing.

- The formation of the ventilation gap.

Preparation of the surface is the removal of all foreign objects, sealing cracks or surface. Wooden walls should be impregnated with antiseptic composition.

Installing the insulation will require creating crate of metal or wooden planks. The shadow step is the width of the insulation plates, which is inserted by the Mospus between the straps. Additionally, the insulation is attached using fungi - special dowels with wide hats. On top of the insulation, a waterproofing membrane must be mounted.

Ventilation gap is 2-3 cm. It allows you to remove moisture from the material of the walls and insulation, while maintaining them with dry and efficient.

If non-accumulated materials are used as insulation - foam, penplex and whether EPPS, the ventilation clearance is not needed.

Laying with your own hands

Sorted and mixed bricks for convenience of a fear of uniform stacks folded along the wall length. To control the position of the dry, the corners are laid out, between which the kapron cord is stretched, according to which the masonry position is controlled.

The first and last (upper) series of bricks is laid out with purple - not filled with a solution of gaps between each 3-4 bricks (this is relevant only for walls with ventilation gaps). Instead of a solution, wooden plates with a thickness of 1 cm are temporarily installed.

Masonry is performed with brick displacement by 1/2 length.

Depending on when the facing layer is made - during the construction of the main walls or after that, the facing layer is either replicated with the main transverse (tonch) rows through 4-5 conventional (spoonful), or attached to the main wall using anchors enshrined in The main wall at the level of gaps between bricks and overlapping gap for about 8 cm.

Useful video

In this video you will learn how to lay a facing brief brief:

Conclusion

Brother's facing brick is a high-quality, reliable material that provides a protective and decorative function. A variety of colors, invoices, a wide selection of the type of material contributes to creating a stylish appearance of the house, the embodiment of designer ideas and advantageously underlines the architectural features of the house.

The durability and strength of brief brief will make the walls in the full sense of impregnable, protect them from moisture, frost or mechanical damage.

In contact with