DIY strip foundation. What is a strip foundation? 1 Construction of a strip foundation

The requirements for the foundation are very high.

The strength and reliability of the foundation are among the main, but not the only tasks assigned to supporting structures.

- Not buried. It is created on absolutely motionless soils - rocks, strong stable soils. It is extremely rare.

- Shallow. Used for construction on durable soils not subject to frost heaving. The depth is less than the level of winter soil freezing.

- Recessed. The depth of such a tape is slightly below the soil freezing level. Used for the most massive and heavy buildings, suitable for most types of soil and hydrogeological conditions.

The choice of the appropriate type is determined by an analysis of all site conditions - soil composition, number and properties of layers, depth of soil water, etc.

What buildings is it suitable for?

Strip foundations are a reliable support for buildings made of various materials:

- Tree.

- Foam and aerated concrete.

- Brick.

- Concrete plates.

The material and number of floors determine the weight of the building, on which the design parameters of the tape depend - the degree of penetration and thickness. Along with the soil characteristics, the building parameters are the main material for performing engineering calculations during design.

How to calculate depth

strip foundation depends on the type of foundation. E if construction is planned option, then it is necessary to rely on the tabular data of SNiP, displaying the depth of soil freezing in a given region.When constructing a shallow type of belt, the composition of the soil, the presence and depth of groundwater are taken into account. The optimal depth is usually considered to be 0.75-1 m, but on stable and dry soils the depth can be slightly reduced.

NOTE!

The most common immersion depth for a shallow belt is considered to be 0.7 m.

How is a shallow strip foundation constructed?

almost completely repeats the recessed version, only with a lower level of immersion.There is a trench in which a drainage layer of backfill is created and a concrete strip is poured.

The base design has fewer capabilities than a full-fledged tape, but for relatively small low-rise buildings its load-bearing capacity is quite sufficient.

Step-by-step DIY installation instructions

Let's consider the procedure for creating a strip foundation:

- Preparation.

- Site marking.

- Digging a trench.

- Laying and arrangement of the drainage system.

- Creation of sandy.

- Production of formwork.

- Installation of reinforcement cage.

- Pouring concrete.

- Wait for hardening.

- Stripping.

- Waterproofing and insulation tape.

- Further work.

The order of actions does not change under almost any circumstances, since all stages are a consequence of previous operations.

Surface marking

The beginning of work consists of removing the top layer of soil and marking the area. For this, wooden stakes are used, which are installed at the intersection points or corner points of the future trench.

The width is selected based on the calculated parameters of the base, but at least 20 cm greater than that of the tape. This is important, since it will be necessary to install formwork inside the trench, and subsequently ensure a sufficient thickness of the backfill layer for the sinuses.

Preparing the trench

Digging a trench is done with an excavator or manually. The second option is difficult, but if difficulties arise with the delivery or approach of construction equipment to the site, it is quite possible. The excavated soil is stored on the sides of the trench or immediately removed from the site.

It is necessary to ensure the same depth, but there is no need to try too hard and level the bottom down to centimeters. The corners of the trench are aligned manually, regardless of the digging method.

Drainage device

The drainage system allows groundwater to be removed from the sand cushion layer, eliminating the possibility of heaving loads occurring in winter.

There are different types of systems:

- Open. It is created on the daytime surface and is intended to drain rain or melt water. Used on dry soils with deep groundwater.

- Closed. Consists of a pipeline system placed in a trench near the belt. Serves to remove groundwater from a layer of sand backfill (pillow), used on soils with the presence or seasonal changes in the level of soil water.

In practice, the closed type is most often used, since there is a danger of water in most cases. A system of special-purpose pipelines is installed that receives and discharges moisture into a drainage well.

For high-quality drainage to work, it is necessary to install a filtration piping and have a slope for the natural movement of water. The filtration layer cuts off small organic particles, preventing the inner surface of the drainage pipes from silting.

This helps extend the life of the system and reduces the risk of failure.

Pillow

The sand cushion is an important and mandatory element of the base structure. Its thickness varies, on average it is 20 cm. Usually used pure river sand or alternately a 10 cm layer of sand, 10 cm of fine crushed stone and again a 5 cm leveling sand layer.

After filling each layer, careful compaction is carried out using construction vibrating machines or hand tools. It is recommended to shed the layers with water, this helps to seal the pillow better.

NOTE!

Experts recommend following the following criteria for the quality of compaction of the backfill layer: there should be no traces of shoes left on the surface when walking. This is important, since settlement of the cushion is unacceptable, as it will cause deformation of the tape with unpredictable consequences.

Installation of formwork

To create the formwork, edged boards with a thickness of 25-40 mm are used (depending on the size of the tape). First, shields with a width slightly exceeding the height of the tape are assembled next to the trench. As they are assembled, the shields are lowered into the trench and fixed from the outside with inclined stops and vertical support bars.

Crossbars are installed from the inside, defining the distance between the panels equal to the width of the tape. The formwork must be strong, ready to accept loads when concrete is poured and hardened. There should be no gaps; all gaps larger than 3 mm must be filled with tow or clogged with slats.

This will eliminate wasteful consumption of concrete when leaking into the cracks.

Reinforcement

Reinforcement is designed to compensate for tensile axial loads that concrete cannot withstand. It easily takes a lot of pressure, but when bending the tape is unstable and breaks immediately.

For reinforcement, a reinforcing belt is created, the main element of which is horizontal working rods made of metal or fiberglass ribbed reinforcement.

To support the rods in the required position, smooth rods of smaller diameter are used, from which vertical elements (clamps) are made, which, in combination with the working rods, form a spatial lattice.

Its dimensions are such that the horizontal rods are immersed in concrete to a depth of 2-5 cm.

Working rods are selected based on the width of the tape. Their diameter for a shallow base is in the range of 12-14 mm (with a width of 30-40 cm) or 16 mm with a larger width.

Knitting reinforcement

The connection of reinforcement frame elements is made in two ways:

- Electric welding.

- Knitting with soft steel annealed wire.

The first option is used for thick rods and is practically not used when constructing shallow foundations. The assembly of the arm belt most often occurs using the knitting method.

A soft wire is used, which quite reliably holds the frame elements, but has a certain degree of freedom, which allows maintaining the integrity of the frame when loads occur during pouring.

Used for knitting special tool in the shape of a hook. A piece of wire about 25-30 cm long is folded in half. The resulting half-loop wraps around both connecting rods in a diagonal direction, the ends rising upward.

Then, grab the fold loop with a hook and, leaning on the second free end, make 3-5 rotational movements, due to which both rods are tightly and firmly connected to each other.

The operation is not complicated, usually the skill is developed on the first day.

Selecting concrete for pouring

There are quite a few grades of concrete designed for different conditions and loads. Since shallow strip foundations are mainly used in low-rise private construction, optimal choice will be concrete grade M200.

It is able to provide the necessary strength and load-bearing capacity of the belt with a relatively low dead weight.

For those who want to approach the issue more carefully, we can recommend using an online calculator to calculate the grade and amount of concrete. The result obtained should be duplicated on another resource to protect yourself from possible errors.

Fill

Filling must be done as quickly as possible, ideally at once. Breaks in pouring for more than a day are unacceptable; in such cases, it is necessary to keep the concrete until it hardens completely and only then continue work. The quality and strength of such a tape is much lower than that of simultaneous casting.

This condition is most easily accomplished by using ready-mixed concrete, which is delivered directly to the site in the mixer. The result is a significant saving of time, and the quality of the concrete will in any case be better than that of a homemade solution.

It is necessary to pour from several points, trying to distribute them as evenly as possible along the length of the tape.. This will allow you to obtain a casting with the same parameters around the entire perimeter, which will ensure high strength of the base.

Features of waterproofing

Exposure to moisture is extremely detrimental to shallow tape. Penetrating into concrete, water sooner or later freezes and tears the material from the inside. This should not be allowed under any circumstances.

There are two types of waterproofing that you can do:

- Horizontal. Protects the lower and upper plane of the tape from moisture penetration from the lower layers of soil and from rain or melt water flowing from the walls. The lower waterproofing is laid before installing the formwork and reinforcing belt, and the upper one is done after the concrete has completely hardened in parallel with the vertical waterproofing. Both layers consist of roofing felt laid in two layers coated with bitumen mastic.

- Vertical. Apply to the outer and inner surfaces of the tape after stripping and complete drying. Materials of different types of action are used - impregnation, coating or pasting. Impregnations are the most effective, but they appeared relatively recently and are little known to builders.

Insulation issues

Insulation of the tape eliminates the formation of condensation. There are two options - external and internal insulation. In the first case, the insulation is installed from the outside, in the second - from the inside.

Experts recommend performing both types of insulation at the same time, since it is impossible to achieve the expected result separately. Taking into account the specifics of placement, it is necessary to use moisture-proof types of heat insulators - foundation penoplex, liquid polyurethane foam, polyethylene foam, etc.

Apply mineral wool in in this case should not be used, as it is capable of absorbing water with complete loss of performance.

Proper care of concrete after pouring

After pouring, it is necessary to regularly water the surface of the tape with water for 10 days.:

- The first 3 days - every 4 hours.

- The next 7 days - 3 times a day.

The tape must be hidden from the scorching rays of the sun under a layer of polyethylene. Watering with water allows you to somewhat equalize the moisture content of the outer and inner layers of the tape, reducing loads and the risk of cracks.

The final hardening of concrete takes a very long time, but you can continue working with the tape after 28 days.

Stripping

Stripping is the procedure for dismantling formwork. It can be done no earlier than 10 days after pouring.

You should not try to speed up the process; the foundation is too important an element of the building to take risks and rely on chance.

Basic mistakes

Most often, sedimentation of the sand cushion occurs due to poor compaction of the backfill layer. In addition, the use of unsuitable materials, especially concrete of the wrong grade, is often encountered.

Some unscrupulous suppliers deliver low-quality material to save money. Experienced experts recommend ordering heavier concrete - instead of M200, take M250. The difference in cost and weight is small, but there is hope that the material will be more durable.

In addition, they often try to reduce the cost of money and labor by abandoning and. These procedures require some time, but, compared to the service life of the base, they are performed very quickly and cannot be neglected.

Useful video

In this video you will learn how to install a strip foundation:

Conclusion

Creating a strip foundation is not so much a difficult task as it requires a full understanding of the meaning of all stages and high-quality implementation of the necessary actions.

For an untrained person with no experience, it is recommended not to deviate from the technology and strictly comply with the requirements of SNiP.

This will help build a strong and high-quality shallow strip foundation.

In contact with

This page provides information about reinforced concrete strip foundations. We will consider the types of these foundations, their scope of application, calculation features and construction technology - from marking to concreting the foundation strip.

What is a strip foundation

A strip foundation is a monolithic reinforced concrete or prefabricated strip that follows the perimeter of the walls of the structure. The tape is laid under the internal and external walls of the building; its cross-section is identical both in the longitudinal contours and at the intersection points.Rice

Compared to installation technology slab foundations, the construction of a strip foundation is simpler to implement and requires less materials. The performance characteristics of the tape allow you to build on it the following types buildings:

- Heavy houses with walls made of concrete, brick or stone, weighing more than 1000 kg/cubic meter;

- Buildings with reinforced concrete and metal floors;

- Light houses made of timber, logs and wooden panels.

Important: the height of structures erected on a strip foundation varies between 1-5 floors. Such foundations are suitable for construction in places where there is a risk of uneven soil shrinkage associated with frost heaving or soil heterogeneity. The reinforced frame of the tape ensures uniform redistribution of loads acting on the foundation, which protects the walls from deformation.

The operational durability of strip foundations depends on their type:

- Monolithic reinforced concrete strips - up to 150 years;

- Prefabricated brick strips - up to 50 years;

- Prefabricated belts made of reinforced concrete blocks - up to 75 years.

Rice

In conditions of dry clay and sandy soils, the minimum depth of laying the foundation strip is 60 cm. On highly heaving soil with a low freezing limit, such foundations are practically not used due to the financial impracticality of laying the strip to a greater depth. An alternative in this case is pile foundations.

Types of strip foundations

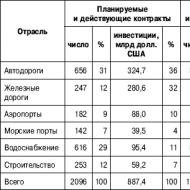

There are 2 types of tape bases:

There are 2 types of tape bases: - monolithic

- prefabricated

Between themselves block structures fastened with cement mortar and reinforcement method. Strip foundations are distinguished according to the degree of deepening: deep-buried, shallow-buried. The depth is determined depending on the load-bearing characteristics of the soil and the expected design load.

Strip foundation technology

It is rational to carry out the construction of a strip foundation in the warm season, from April to October. To erect the belt, you do not need to use special equipment; you only need a concrete mixer and small-scale mechanization equipment - a welding machine, an angle grinder, an electric drill.Stage No. 1 - preparatory work and marking

Construction begins with preparing the site for construction - the area is cleared of debris and stones, vegetation and tree roots are removed. It is necessary to remove a layer of fertile soil (turf) to the depth of a spade bayonet. If the site has a natural slope, the site is leveled one by one horizontal level.Important: marking the axes of the foundation is done using cast-off boards and wire or construction cord. The wear shield consists of two stakes driven into the ground, which are connected by a horizontal belt. The twine is fixed to the board using a self-tapping screw or nail screwed into the board.

Rice

When marking the contours, the stripping boards are placed beyond the axes of the foundation at a distance of 1-2 meters, so that during the digging of trenches the structures do not interfere with work. The design outlines of the foundation are transferred to the site - initially the external contours of the building are indicated, then the width of the tape is set back from them and the string is pulled along the internal contour.

Rice

The marking of the internal walls of the building is carried out upon completion of the layout of the external axes. During work, you need to check the right angles of the markings. This is done using the Egyptian triangle method - in one of the corners from the intersection, a mark is made on the first string at a distance of 3 m, on the second - with an indentation of 4 m. Next, the diagonal is measured; at the correct right angle, its value is 5 m.

Rice

Stage No. 2 - digging a trench and filling the compacting pad

The trench for the foundation strip can be developed manually or using excavators. When using special equipment, the bottom of the trench must be leveled to one horizontal level.

Rice

Upon completion of the formation of the trench, a compacting cushion is added. Its thickness is selected based on the degree of heaving of the soil; under normal conditions, a 20 cm thick bedding is used, consisting of two identical layers of crushed stone and sand. Sand is poured first, watered and compacted manually. If necessary, gravel can be replaced with fine crushed stone.

Stage No. 3 - installation of formwork

To create formwork, planed boards with a thickness of over 0.5 cm are used. It is acceptable to use boards processed on one side (the smooth surface is installed inside). The boards are knocked together into panels with a height equal to the height of the ground part of the foundation and installed along the perimeter of the trench.Important: the formwork must be fixed using side braces and an upper transverse strip, which prevent deformation of the form under concrete pressure. Make sure that the nails and screws that connect the panels do not protrude onto the inner surface of the formwork.

Rice

It is important to achieve verticality of the formwork walls, which is controlled using a level. The part of the formwork raised above the ground forms the base part of the foundation strip. Holes are pre-cut in the panels to accommodate sewer and water supply lines, into which metal pipes are installed to form cavities in the reinforced concrete structure.

Rice

The walls of the formwork and the internal surfaces of the trench must be covered with waterproofing material, which will prevent leakage of water and cement laitance from the concrete mixture.

Stage No. 4 - assembly of the reinforced frame

To reinforce the foundation, a double-circuit frame is used, consisting of an upper and lower longitudinal belt connected by vertical jumpers. The number of rods in the longitudinal belts is selected based on the width of the tape (3-5 pieces); rods with a diameter of 12 to 16 mm are used. Vertical jumpers are placed in increments of 20-30 cm.

Rice

For convenience, the frame is assembled outside the trench, after which the finished structure is placed inside the formwork. Each side of the frame should be removed from the contours of the concrete body of the foundation at a distance of 4-5 cm; special mushroom stands are used to raise the frame above the bottom of the trench; it is not recommended to use brick for this purpose.

Rice

Important: at the junction of the walls and corner parts of the foundation, the frame is joined using curved reinforcement and is additionally reinforced with L-shaped rods. Cross joining cannot be used as it reduces the strength of the structure.

Stage No. 5 - concreting

For concreting the foundation strip, concrete grade M200 or M300 is used. When mixing yourself, the proportions used are 1:2:4 (cement-sand-aggregate). Fine-grained crushed stone with a particle size of 40-70 mm is used as a filler.It is important to achieve the optimal consistency of the composition - when stirring with a shovel, it should not flow around the metal surface, but should be mixed with considerable force. When using excessively liquid concrete, the aggregate may settle at the bottom of the trench, which should not be allowed.

Rice

When pouring the foundation, gutters are used - pouring concrete from a height of more than 1 m from the bottom of the trench is prohibited, as this can lead to its delamination. Do not allow intermediate hardening of concrete; layers should be poured before the previous layers set. After concreting, the tape must be pierced with a reinforcing bar to remove air cavities from it.

Dismantling of the formwork is carried out 5-7 days after pouring the foundation; concrete needs 25-30 days to fully gain strength.

Frame reinforcement technology

The strength of the foundation is ensured by the reinforcement structure, without which it is impossible to form a complete foundation. Reinforcement work includes several stages:- installation of formwork - a plank frame is installed along the perimeter of the future building, the walls of which are lined with parchment on the inside, thanks to which it will be easy to remove later;

- driving vertically located reinforcing bars into the soil - the length of the reinforcement is comparable to the depth of the foundation. It is necessary to bury the rods at a distance of 50 mm from the walls of the formwork, while they are embedded in the ground in increments of up to 600 mm;

- installation of stands on the bottom (height up to 100 mm), on top of which horizontally located reinforcing bars are laid: the function of stands can be performed by halves of bricks installed on the edge;

- horizontal rows connected to vertical rods;

- fixing structural elements at intersections by welding or wire.

Useful materials

Strip foundations are the most common, but are not applicable on all soils. To begin building such a foundation, it is necessary to carefully examine the soil and decide what thickness and height the tape should be.

In this article we will describe in detail all the stages of constructing a strip foundation, from digging a trench, reinforcement, formwork and ending with pouring concrete.

Geology of the soil under the foundation

This is the most important stage by which the following data is determined:

- Type of soil and its design resistance.

- Freezing depth.

- Ground water level.

- The degree of soil heaving and its homogeneity.

After geology, you can begin designing the foundation itself.

Depending on the architectural solution, that is, the initially planned building, the weight of the house is determined, including the weight of the foundation, snow, wind and payload. The type of foundation, in our case strip, can be deep or shallow.

The next step will be to determine the parameters of the foundation itself, namely:

- Foundation width.

- Height of the recessed part.

- Height of the above-ground part.

- Is drainage required?

To determine the width of the foundation, you need to divide the weight of the house by the area of the foundation support, and the resulting value should be 20% less than the calculated soil resistance.

To increase the area of foundation support, a widening (heel) is made, which distributes the load over a larger area.

We described this in more detail in our previous article - how to calculate the weight of a house.

For a deep foundation, the laying depth should be 20 cm below the freezing depth. For a shallow foundation, everything depends on the soil, or rather on the heaving depth, freezing depth and groundwater level.

For an approximate determination of the depth of a shallow foundation, see the table.

- The maximum height of the above-ground part of the strip foundation should not exceed four times the width of the foundation strip.

- The above-ground part should be smaller than the underground.

- The optimal height of the above-ground part is 40-50 cm.

Performing markings on the site

By finished project it is necessary to carefully measure all the corners of the future foundation and set the pegs. The stakes are placed along the outer and inner perimeter of the foundation; a string is stretched between the stakes, defining the contours for digging the foundation trench.

At this stage, a trench is being dug, the depth of which should be suitable for the foundation design, taking into account the sand cushion and formwork. There are two ways to dig a trench: with a tractor using a narrow bucket, and manually (with shovels). The tractor will handle it much faster, but with shovels it turns out smoother and more accurately.

The sand cushion is made about 20 cm thick, moistened with water and compacted well.

In some cases, it will be much more convenient to first tie the frame in a trench, and only then place the wooden formwork.

Stages of frame reinforcement:

- Stones or bricks 5-6 cm high are placed at the bottom of the trench, the purpose of which is to lift the reinforcement cage in order to create a protective layer of concrete below.

- Next, longitudinal reinforcement rods, pre-bent at the corners, are laid out on the bottom.

- Next, pre-made clamps are put on the bottom row of reinforcement, they are also frames, they are also transverse reinforcement.

- The clamps and a row of lower reinforcement are connected with knitting wire.

- If the height of the tape is more than 80 cm, then structural rows of reinforcement are added, one row or more.

- Next, the upper longitudinal reinforcement bars and L-shaped clamps at the corners are added to the frame and tied with wire.

- To provide a protective layer of concrete on the sides of the foundation, special plastic rings are used that help hold the frame in the desired position.

We highly recommend that you read our article about calculating the reinforcement of a strip foundation, which describes in detail all the nuances of selecting reinforcement and corner reinforcement schemes.

The formwork is made of wooden boards and reinforced with many bars, which are additionally rested on pegs into the ground. Also, to strengthen the formwork, metal wire ties are used, or pins are tightened in plastic tubes.

The installation of formwork must be approached very responsibly, since liquid concrete has a large bursting force, especially if the height and width of the formwork are large. Quite often, inexperienced builders’ formwork breaks and concrete flows onto the ground. To avoid this situation, strengthen the formwork as much as possible. And remember that more concrete pressure is created in the lower part.

Do not forget about installing sleeves for communications (water, sewerage).

It is very important that the foundation be monolithic, and to achieve this condition, it is necessary to pour concrete into the trench at one time. This is unlikely to be achieved manually using a concrete mixer, so it is better to order the delivery of ready-made concrete in mixers.

- The time between concrete truck deliveries should not exceed two hours.

- It is better to pour it in layers, spreading the concrete around the entire perimeter.

- To obtain a more plastic (liquid) concrete mixture, ask to add a plasticizer to the mixer.

- Excess water in concrete reduces grade strength, increases the number of shrinkage cracks and increases the number of pores in concrete, making it less moisture resistant. Avoid excess water during the kneading process.

- During pouring, you need to use a deep vibrator, which compacts the concrete and expels air.

- Try to level the plane of the foundation strip as much as possible.

- Within a week, you need to shed the surface of the foundation with water, this will avoid shrinkage cracks and help the concrete gain grade strength. We also recommend covering the tape with film.

The foundation is ready. All that remains is to perform vertical and horizontal waterproofing, as well as an insulated blind area, which reduces the depth of freezing and drains excess water from the foundation.

We wrote a separate article about how long the foundation should stand, where we consider options for settling from 10 days to six months.

The foundation is a very important structure of a building. Up to a third of all work may be spent on work below the ground floor level. financial investments into construction. In addition, the situation is complicated by the fact that after the workers begin constructing the box, access to the foundation will be limited, and its repair is very labor-intensive. The choice of type of support for a building depends on its design, the presence of a basement and the characteristics of the foundation soil. One of the most common types is a strip foundation.

The structure is a stone strip that serves as a support for the walls and can be made from the following materials:

- reinforced concrete;

- brick;

- rubble stone.

The most common option is to make it from concrete with reinforcement. This solution can be implemented using two technologies:

- prefabricated strip foundation;

- monolithic design.

When using brick, you need to pay attention to its brand in terms of strength and frost resistance. If possible, it is better to focus on other materials (concrete, rubble). The foundation strip is provided for all walls, both load-bearing and non-load-bearing. There is no need to lay foundations under the partitions.

The strip type is suitable for the construction of massive buildings on soils with sufficient good performance. It is not suitable for swampy soils. If there are bulk soils, they should be replaced with medium-sized sand with layer-by-layer vibration compaction. If the soil has high strength, some types of strip foundations can even be used for the construction of multi-story buildings. On a solid foundation, you can easily erect buildings of 9-12 floors. When using prefabricated blocks, a monolithic reinforced concrete stiffening belt will be required.

Types of strip foundations

There are several design options for strip foundations, each of which is used for certain cases and has its own load-bearing capacity. As a general classification, the following division can be given:

- non-buried foundations;

- shallow strip foundation;

- buried foundations.

These types are applied depending on certain circumstances. When choosing, you need to pay attention to:

- load from the building on the belt;

- groundwater level;

- depth of soil freezing;

- required base height.

Non-recessed tape

Scheme of a non-buried strip foundation.

Suitable for small buildings made of lightweight materials. For stone buildings(made of brick, aerated concrete, reinforced concrete) cannot be used. There are two types:

- reinforced concrete belt;

- reinforced concrete rib.

These types can only be built using monolithic technology. When using concrete blocks (FBS blocks), the structure may collapse with minor soil movements. In this case, concrete absorbs compressive loads. To accommodate bending, reinforcing bars are placed in the structure. It is necessary to install cushions of medium-sized sand or sand and gravel mixture.

The reinforced concrete belt has a height less than the width, and the edge is the opposite. The use of a rib as a strip base allows you to raise the base and provide greater reliability. With the same cross-sectional area, the rib will withstand greater bending loads compared to the belt.

This can be explained by the fact that the tape is calculated as a beam on an elastic foundation. To determine the deflection, it is necessary to calculate the moment of inertia, which is found by the formula:

where b is the width of the section, and h is its height. It can be seen from the formula that the height of the section most strongly influences the magnitude of the moment of inertia. The greater the value obtained from the formula, the greater the bending the structure will withstand.

This type of foundation is used when high level groundwater (water is located at a distance of less than 1 meter from the surface of the earth). Suitable for the construction of frame extensions, verandas, terraces and the like.

Important! For any type of strip foundation, it is necessary to provide a support pad. It is made from sand (coarse or medium) or a sand-gravel mixture. The thickness of the pillow is determined depending on the characteristics of the soil (most often 30-50 cm).

Shallow belt

Scheme of a shallow strip foundation.

Unlike the previous one, this type of foundation has a slight penetration into the ground. The depth of support is located within 0.5-0.6 m from the surface. There can be two types:

- rectangular section;

- T-shaped section.

The second option has greater load-bearing capacity, but requires increased material consumption and increases labor intensity. The T-shaped section combines a belt and a rib placed on it. The lower widened part absorbs bending and increases the support area, i.e. distributes the load, and the upper vertical loads from the building.

Scheme of a T-shaped shallow strip foundation.

Both of these types can be built in a monolithic or prefabricated manner. When choosing a T-section from prefabricated elements under concrete blocks lay special factory-made pillows (FL slabs).

Important! When supporting foundations above the freezing depth of the soil (accepted according to the joint venture “construction climatology”), it is necessary to provide for their insulation and replacement heaving soil on medium coarse sand. Otherwise, cracks will appear in the structure.

Shallow types are used when the groundwater level is located at a distance of 1 meter or more from the ground surface. On such bases you can install frame or wooden houses(timber, rounded log). Stone houses can only be placed on a T-shaped strip, since with a rectangular section and small movements of the soil, cracks may appear along the walls.

More details: .

Recessed tape

Scheme of a recessed strip foundation.

This type is the most reliable. It allows you to design a basement in a building. The depth of placement is determined based on:

- height of the basement room;

- soil freezing depth;

- location of soil layers and their bearing capacity;

- groundwater level.

It is necessary to support the structure on a layer of soil with normal bearing capacity; this can only be determined by conducting geology at the building site. The groundwater level should be 50 cm below the base. If there is a basement, the lower edge of the concrete wall is lowered 200-300 mm from the basement floor level.

Deep foundations, as well as shallow ones, can be of two types: rectangular and T-shaped. For the construction of multi-storey buildings, T-shaped ones are used; for private housing construction, rectangular ones can be used. Monolithic and prefabricated reinforced concrete are used for production.

When using prefabricated elements, a monolithic belt is made along the edge of the tape, which will connect the individual blocks into a single whole and evenly distribute the load from the walls. The blocks must be installed with a bandage of at least 250 mm. The thickness is selected depending on the thickness of the walls of the building box. During installation T-shaped foundations prefabricated pillows for blocks are selected by calculation. Using calculations, the required area of the support base is found.

Recessed tapes may be suitable for the construction of houses made of concrete, brick, aerated concrete or other materials. If the groundwater level is high, their use is possible, but it is necessary to provide reliable waterproofing and a drainage system.

The material of the article can be summarized in the table.

| Foundation type | Section types | Application area |

| Non-buried (on the surface of the earth) |

Belt | Small light buildings, frame one-story buildings at a high groundwater level (GWL) on solid foundations |

| Edge | ||

| Shallow (supporting the sole at a depth of 50-60 cm from the surface) |

Rectangular | Frame and wooden buildings 1-2 floors with ground level below 1 m from the ground surface |

| T-shaped | Frame, wooden, aerated concrete houses up to three floors with groundwater level below 1 m from the ground surface | |

| Recessed | Rectangular | Frame, wooden, aerated concrete houses of more than 2 floors, brick and concrete buildings up to 3 floors |

| T-shaped | Brick and concrete buildings of 3 floors or more |

If you choose the foundation for the building frame wisely, it will not cause problems during operation and will not require serious repairs to the load-bearing structures, so the choice of the type of strip foundation must be approached with all responsibility.

The strip foundation can be called the most popular in the construction of private houses, as it has fully justified itself over many decades of operation. It is quite simple to set up and does not require particularly complex devices or special equipment.

Of course, in order for the structure to be reliable and durable, you can only partially make a strip foundation with your own hands, that is, carry out the basic work of digging a trench, installing formwork, installing and tying reinforcement bars, waterproofing and insulation. But it can be easier and more reliable to order manufacturing and filling from companies that specialize in this work.

To find out why the strip foundation is so popular in construction, you need to consider all its positive and, of course, existing negative qualities.

Advantages and disadvantages of strip foundations

A strip foundation is a monolithic strip of concrete mortar on which all load-bearing walls buildings.

Strip foundation - a reliable basis for the construction of building walls

Strip foundation - a reliable basis for the construction of building walls This type of base is used in the following cases:

- For the construction of private houses and outbuildings from materials with significant mass, such as stone, concrete, brick, cinder blocks and other materials.

- In cases where in in general terms The building is supposed to have an underground garage, ground floor or basement.

- For the construction of houses with heavy floors or attics.

- In regions where predominantly heterogeneous soil prevails.

It should be noted that installing a strip foundation is suitable for almost all types of soil, with the possible exception of subsidence and peat bogs - this must be taken into account when choosing the type of foundation for building your own house.

To know what can be expected from a strip foundation during operation, you need to have information about the advantages and disadvantages of this design.

Advantages:

- The joint strip foundation is specially designed to withstand heavy loads, no less than a monolithic foundation.

- It is distinguished by the comparative simplicity of preparatory measures, which can be completely carried out independently.

- A strip foundation always has a long service life, of course, if it is constructed correctly and the required degrees of structural protection are provided (waterproofing and insulation).

- An advantage can be considered the variety of specific types of strip foundations, from which you can choose the one that is most suitable in terms of technological and financial capabilities.

- A tape base will cost much less than a monolithic one, although it is practically not inferior to it in strength.

- This design allows for better thermal insulation of floors in the house, creating a multi-layer insulation layer.

Flaws:

- Strip foundations are not suitable for installation in some soils.

- According to construction technology, the entire thickness of the foundation must be poured in one go, and it is very difficult to prepare such an amount of concrete yourself. In this regard, there is a need to turn to construction manufacturing companies that have special equipment and machinery.

- The work, even in preparation for pouring concrete, is quite labor-intensive and will take a lot of time. It will be difficult to do without helpers.

As can be seen from the presented qualities of the strip foundation, the positive ones have a significant advantage over the negative ones.

Types of strip foundations

There are several types of strip foundations, which differ according to some criteria, and the first of them is the depth of its occurrence.

- For example, for massive houses built from heavy building materials, a deep foundation is required, which must be built to a depth of 250 ÷ 300 mm below the freezing level of the soil in the region where the building is constructed.

- Another type of strip foundation is shallow. It is used for light frame buildings, and its total depth does not exceed 550 ÷ 600 mm.

The diagram shows several main types of strip foundations

The diagram shows several main types of strip foundations Strip foundations are divided not only into two types, but also into several types:

- The monolithic type of foundation is the most used for various buildings. It is erected from concrete mortar and with mandatory reinforcement. This foundation is attractive due to its simplicity of design and ease of construction, along with its inherent durability and strength.

- Prefabricated foundations are used less frequently for the construction of private houses. This type of base is assembled from ready-made concrete blocks, which are manufactured in factories. They are delivered to the venue construction work and installed in a prepared trench using heavy equipment.

The blocks are installed back to back, and the gaps between them are filled with concrete mortar and completely sealed on the outside with waterproofing material.

This type of foundation is not suitable for unstable soils, since rupture and deformation of the entire foundation, and therefore the building standing on it, can occur at the joints.

In addition, you will have to pay a fairly large sum for the delivery and installation of blocks to their permanent location (using loading and unloading and lifting equipment). However, in fairness it must be said that the blocks themselves will cost less than the entire complex of necessary materials for pouring a monolithic foundation belt, and will also save builders from a lot of heavy construction work. For example, you won’t have to knock down and install formwork, or lay and tie reinforcement mesh.

Prefabricated or block foundation good for two or three-story houses, built from concrete slabs or brick. If you have the financial opportunity and the type of soil is suitable for installing blocks, then this type of foundation will be a good choice for building a large cottage.

Materials for arranging a strip foundation

If, nevertheless, a decision is made to build a building on a strip monolithic foundation, you need to buy everything necessary materials for its construction.

For this you will need:

- Ruberoid or dense polyethylene film - for waterproofing the formwork.

- A board 15 ÷ 20 mm thick and a block 20 × 30 mm - for installing formwork.

- Steel wire - for tying reinforcement and tightening, if necessary, formwork boards.

- Reinforcement with a diameter of 10 ÷ 15 mm - for installing a reinforcing belt.

- Nails or self-tapping screws - for installing formwork.

- Sand and crushed stone - for preliminary filling of “pillows”.

- If the concrete is still mixed independently, then it will need cement no lower than M400, sand and mid-fraction crushed stone or gravel. The solution is made from these materials, taken in proportions 1: 2: 4.

Sequence of work to create a strip foundation

To be confident in choosing a foundation, it is necessary to carry out some preparatory activities.

Foundation calculation

It is imperative to find out the type of soil on the site for building a house and the depth of its freezing in a particular region, as well as the depth of groundwater passage. To clarify all these features, you need to contact a design and construction organization that will conduct a geodetic study, carry out necessary calculations and will create an accurate foundation design based on the analysis obtained as a result of research.

If you start drawing up a project yourself, you may not take into account some nuances that will subsequently lead to the destruction of the walls of the house. This is especially true for buildings with several floors.

If you plan to build a small building, such as, for example, country house, garage, barn, chicken coop or bathhouse, then you can try the foundation, taking into account the recommendations of SNiP II-B.1-62. And it’s even easier - use a special table that allows you to get enough without making special calculations exactly exactly determine the required depth of the strip foundation, depending on the type of house and soil characteristics:

| Type of building | Depth of strip foundation (mm) depending on the type of soil | ||||||

|---|---|---|---|---|---|---|---|

| Rocky soil, opoka | Dense clay, loam that molds in the hand | Packed dry sand, sandy loam | Soft sand, sandy loam, silt soil | Very soft sand, sandy loam, silty soil | peat bog | ||

| Barn, bathhouse, outbuildings. the buildings | 20 | 200 | 300 | 400 | 450 | 650 | |

| One-story country house with attic | 30 | 300 | 350 | 600 | 650 | 850 | A different type of foundation is needed |

| Two-story cottage | 50 | 500 | 600 | Requires specialist calculations | Requires specialist calculations | A different type of foundation is needed | |

| Two or three story mansion | 70 | 650 | 850 | Requires specialist calculations | Requires specialist calculations | Requires specialist calculations | A different type of foundation is needed |

| The table shows the average load force on the ground of buildings of various types | |||||||

| In each specific case, an individual calculation is definitely welcome | |||||||

| For reference: 1 kg = 9.81 N; 1 kN = 101.9 kg; 10 kN = 1019 kg | |||||||

| The table is compiled based on data from British government building codes 2010 | |||||||

Site marking

When the necessary foundation calculations have been made, a architectural plan building and, accordingly, the location of the load-bearing walls is determined, markings are made on the site chosen for construction.

The most important question- correct marking of the foundation on the ground

The most important question- correct marking of the foundation on the ground - Before marking, the future site must be cleared of foreign objects and debris, and the top fertile layer of soil approximately 120 ÷ 150 mm thick must be removed. Organic residues can lead to biological decomposition processes, which is undesirable for basements.

- Preliminary work is carried out on the prepared site. marking the corners of the future building by driving in pegs.

Next, the evenness of the arrangement is carefully checked and the distance between them is specified. The pegs are rearranged as needed. A strong cord is pulled over them, with the help of which it will be easier to control the straightness of the corners and determine the correct direction of the foundation strip.

- Sometimes pre-made wooden ones are used to mark the corners. details - rectangles. First, place one rectangle at the desired point and secure it.

Next, two cords are tied to it at a distance the width of the trench under the foundation, they are pulled to the next place where the second corner is installed, and then the stretched cords are tied to it.

In this way, all four corners of the house are marked, and if load-bearing walls are also provided inside the building, then they are marked.

- After all the angles have been set, it is necessary to check the length of the diagonals of the designated rectangle or square. If they are equal, then all angles are set correctly.

- Next, along the cord, you can sprinkle dry lime powder - it will visually show the direction, and perhaps reveal some errors.

- When marking the contour of the foundation and the internal walls of the house is completed, you need to mark the foundation for the porch or terrace in the same way.

If you plan to install a brick stove or fireplace in your house, then it makes sense to immediately take care of the foundation for this structure. However, the tape for the house and the stove under the stove should not be rigidly connected to each other.

After the marking has been carried out, you can begin fairly large-scale excavation work.

Digging a trench

- Along the marked lines, trenches are dug to a depth specified in the calculations of specialists, and which will depend on the type of building being erected on the foundation.

- Digging a pit should begin from the bottom corner of the foundation - this will help maintain the same depth of the trench throughout its entire length.

- When digging soil, you should try to keep the walls of the trench level and vertical. If the soil begins to crumble around the ground, then temporary supports are installed in weak places.

- During the work process, measurements are periodically taken of the depth and slope of the bottom of the trench being dug. If the foundation is installed on a slope, then it is important that the trench has the same depth along the entire perimeter of its structure.

Preparing the pit bottom

- At the bottom of the finished trench, it is necessary to arrange a sand cushion, which should have a thickness of at least 150 ÷ 200 mm in a well-compacted form. It will help to properly redistribute the loads created by the mass of the structure onto the finished foundation. This technique is especially important if construction is taking place on unstable, heaving soils.

- Next, it is recommended to make a sand cushion roofing felt flooring, which will protect the sand cushion from erosion and will prevent laitance from being absorbed from the concrete when pouring the solution into the pit.

In addition, roofing felt will serve as waterproofing for the underground part of the foundation. The material is not only covered at the bottom, but also rolled onto the walls of the trench by 150 ÷ 200 mm.

Installation of formwork

It is installed in the prepared trench. It can be knocked down from boards, which will be dismantled after the solution hardens, or it can be made permanent, thereby insulating the foundation at the same time.

- If it is decided to install the formwork from boards, then panels are knocked down from them and installed vertically at the bottom of the trench. The formwork should rise above the ground to the height to which it is planned to raise the basement of the house, but usually no less than 350 ÷ 400 mm.

— The shields are fastened together by crossbars, and on the outer sides they are supported by scraps of timber. Sometimes, in order for the plank walls not to diverge when pouring concrete under pressure, it is necessary to additionally twist them with steel wire.

— If it is planned to make holes in the foundation for communications, then a piece of pipe is installed as a spacer between the panels, inside the formwork.

— When installing a wooden structure, you need to periodically check its levelness - this is done using a building level, otherwise the foundation may turn out crooked and will have to be leveled after it is ready.

- A permanent foundation consists of blocks of , which are installed on top of each other and are held in place by the jagged cutouts present on the edges of the blocks and their corresponding grooves. Expanded polystyrene in such formwork can have different thicknesses and serves as a good insulation material for the structure. Such blocks are produced in different widths, so they can be selected for any foundation.

The blocks do not require spacers or additional fastenings - they themselves are fully designed to reliably hold the concrete poured into them.

- Another formwork option that can be called combined. It consists of installed board panels, and inside the formwork, insulation, approximately 30 mm thick, is pressed against them - this can be expanded polystyrene or penoizol.

The material will not only insulate the foundation, but will also not allow cement laitance to leak out through the gaps between the boards or premature evaporation of moisture from the poured concrete, which means that the process of maturation and strength gain will take place in an optimal manner.

Installation of reinforcement grid

The next step is to install it in the formwork. It is made from a metal rod having a diameter of 8 ÷ 15 mm. The rods are cut into sections equal to the length of the walls, and they intersect at their corners. It is not recommended to fasten the rods by welding, since this will cause them to lose their mutual mobility and, when the structure shrinks, this can destroy the foundation. Therefore, they are twisted with steel wire.

If insulation material is installed inside the formwork, then it is desirable that the perpendicular sections of the reinforcement fit into the insulation - this way it will be securely fastened to the edges of the formwork.

An accurate calculation of the reinforcing belt is carried out by foundation designers taking into account m numerous criteria - the type and total mass of the building, soil stability, seismic characteristics of the region, and other quantities.

Pouring the foundation

If this option is not possible for one reason or another (for example, the absence of a corresponding company or completely unacceptable prices), then the concrete is poured in layers. But even in this case, you cannot do without mechanizing the process, which means you will definitely need a concrete mixer.

- When ordering finished material, the concrete solution is mixed at stationary production units in the required proportion, and delivered in special vehicles equipped with a concrete mixer and feed mechanisms.

— Next, a special gutter is installed through which the solution flows into the prepared formwork. It must be distributed using a shovel along the entire length of the structure until it is filled to the intended top.

— The surface of the concrete is leveled and left to set, mature and gain strength.

— The hardening time for such a structure is about four weeks in the warm season. Some work, for example, stripping and preparing for further operations, but without a significant load on the tape, can begin after 16 ÷ 20 days.

It is not recommended to fill the foundation in winter, but if it is — necessary measure, then both the composition of the concrete solution and the completion time of the poured structure will be completely different. This is described in more detail in the corresponding article on our portal -.

- In this case, the work will be carried out independently, they are carried out in the following sequence:

— First of all, the solution for pouring is prepared. As mentioned above, it will require cement and sand in proportions of 1: 2 or 1: 2.5, as well as 4 parts of crushed stone. The mixture is poured with water and kneaded.

- If all the materials are mixed in, then they are placed in the same proportions and a solution is prepared, which is then immediately poured into the formwork. Using such an installation, the work will certainly go much faster, and with the support of good assistants, the work can often be completed in one day.

- If the solution is mixed manually, then you will have to act in stages. So, the first layer of concrete solution is poured into formwork 150 ÷ 200 mm thick and compacted well with a wooden block. The entire formwork along the entire length along the perimeter must be filled with a completely uniform layer of equal thickness.

The next day, the same procedure is carried out, and so on until the formwork is filled to the top.

— It is recommended to cover the poured foundation with burlap, and if concrete works carried out in the summer heat, it is covered with plastic film so that rapid evaporation of moisture does not occur and the concrete hardens evenly.

A foundation made in layers matures faster than one poured at once. However, its strength is significantly lower, and there is a possibility of damage to the structure in winter during severe frosts if moisture suddenly appears between the layers. Therefore, it is necessary to apply a waterproofing coating to the foundation poured in this way, and it is also advisable to insulate it.

Prices for popular models of concrete mixers

- To mix the solution, you need to use materials that are free of soil and clay - gravel, sand and water.

- The proportions of the solution may vary, but crushed stones or gravel should always be taken 1.5 ÷ 2 times more than sand.

- Water in the solution should be approximately 50% of the mass of cement (not to be confused with volume! )

- If you have to use wet sand to prepare concrete, this must be taken into account when adding water to the concrete mixer so as not to make the solution too liquid.

- When mixing and pouring the foundation in cold weather, it is recommended to mix the solution with heated water - this will speed up the setting and hardening of the concrete.

- If the solution is too thick, then after pouring the solution into the foundation, tamping or frequent piercing with a metal rod is necessary. This process is carried out to remove the air remaining in the solution, otherwise so-called sinks may form inside the foundation.

- In addition, the formwork with the newly poured mortar is tapped with a wooden hammer - this process also helps the air to escape to the surface of the mortar.

- Removal of formwork is carried out no earlier than 5 ÷ 7 days after pouring the solution, and further large-scale actions can be carried out only after a month.

- Insulation and waterproofing of the foundation will be mandatory, as already mentioned, when pouring it layer by layer. However, it is better to make it a rule that these technological operations should be carried out in any case. This will dramatically increase the strength and durability of the foundation and, naturally, the entire structure. How to carry out the foundation - read in the publications of our portal.

It should be noted that a strip foundation is the optimal basis for many buildings, and its implementation is much easier than monolithic slab. And at the end of the article - a video example of the correct arrangement of a strip foundation:

Video: how to properly pour a strip foundation